Measures to eliminate jerks in the brakes

Shocks in the brake mechanisms appear in three forms:

- The steering wheel vibrates in the direction of the turn. This is most noticeable when applying the brakes at vehicle speeds of 100-140 km/h.

- When the brakes are applied, the body of the car sways back and forth. The degree of buildup does not depend on the speed of the car.

- When the brakes are applied, pulsating forces tend to push the brake pads back. This pulsation is transmitted to the brake pedal.

The most likely causes of brake pulsation are:

Excessive beat (wobbling from side to side) brake disc, uneven brake disc thickness

- If the runout exceeds 0.04 mm at a distance of 10 mm from the edge of the brake disc, this indicates uneven wear of the brake disc due to uneven fit of the brake pads.

- If the runout is less than 0.04 mm, there is no uneven wear.

Thermal deformation of the brake disc

- Repeated emergency braking can increase the temperature in some areas of the brake disc up to about 1000°C, as a result of which the brake disc is deformed.

Due to corrosion, the thickness and coefficient of friction of the brake disc change

- If the vehicle is left parked on a slope for a long time, the brake disc surfaces will corrode.

- The thickness of the corrosion is uneven and in some places the disc has a wavy surface, as a result of which the coefficient of adhesion changes, causing the appearance of reactive forces.

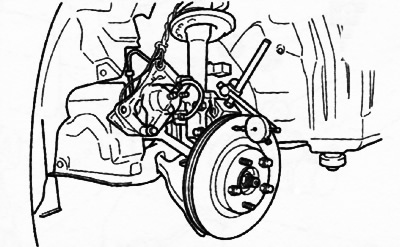

Checking the axial runout of the brake disc

1. In order to fix the brake disc with the hub, insert the washer (thickness 10 mm, inner diameter not less than 12 mm) between all hub bolts and nuts, then tighten all hub nuts.

Note: Components of special equipment (49 8017 001 or 49 G019 003) can be used as suitable nuts.

2. After tightening all hub nuts to the same torque, place a dial indicator on the working surface of the brake disc 10 mm from the outer edge of the disc.

3. Rotating the brake disc, measure the amount of axial runout.

Note: Front brake disc runout limit: 0.04mm.

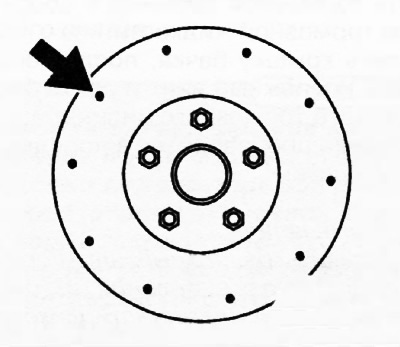

Checking the uneven thickness of the brake disc

1. Use a special cleaner to clean the friction surfaces of the brake disc/brake pads.

2. With caliper (micrometer) measure the brake disc at the points indicated in the figure.

3. Subtract the minimum value from the maximum and, if the result is not correct (0.015 mm), grind the brake disc with a special milling machine.

Attention. Do not exceed the permissible minimum size of the brake disc.

Checking the thickness of the brake disc

Attention. Grooving the brake disc with its removal from the car can cause increased wear in the future. Perform turning of the brake disc without removing it from the car using a special milling machine.

Measure the brake disc thickness. If the measured value is not correct, replace the brake disc with a new one.

Note:

- Minimum brake disc thickness: 26.0 mm.

- The minimum thickness of the brake disc after turning: 26.8 mm.

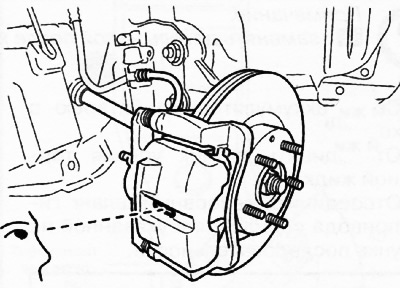

Checking the thickness of the brake pads

1. Raise the front of the car with a jack and install the support stands.

2. Remove the front wheels from the vehicle.

3. Check the residual thickness of the brake pads.

Note: Minimum thickness of brake pads: 2.0 mm.

4. If the thickness of at least one of the brake pads is less than the minimum, replace the brake pads of the right and left wheels in one set.