Micrometer-device designed for measuring linear dimensions by the absolute contact method in the region of small dimensions with high accuracy (from 0.01 to 0.001 mm), the converting mechanism of which is a screw-nut micropair.

The micrometer must be kept clean. Be careful not to drop the micrometer, as its bracket may become deformed, resulting in inaccurate measurements.

The action of the micrometer is based on the movement of the screw along the axis when it is rotated in a fixed nut. The movement is proportional to the angle of rotation of the screw around the axis. Full revolutions are counted on a scale printed on the stem of the micrometer, and fractions of a revolution are counted on a circular scale printed on the drum. It is optimal to move the screw in the nut only to a length of no more than 25 mm due to the difficulty of manufacturing a screw with an exact pitch over a longer length. Therefore, the micrometer is made in several sizes for measuring lengths from 0 to 25 mm, from 25 to 50 mm, etc. For micrometers with measurement limits from 0 to 25 mm with closed measuring planes of the heel and micrometer screw, the zero stroke of the drum scale must exactly match the longitudinal stroke on the stem, and the beveled edge of the drum must coincide with the zero stroke of the stem scale. For measurements of lengths greater than 25 mm, a micrometer with interchangeable heels is used; the setting of such micrometers to zero is carried out using a setting measure applied to the micrometer, or end measures. The measured product is clamped between the measuring planes of the micrometer. Usually the screw pitch is 0.5 or 1 mm and, accordingly, the scale on the stem has a division value of 0.5 or 1 mm, and 50 or 100 divisions are applied on the drum to obtain a reading of 0.01 mm. This reading is the most common, but there are micrometers with readings of 0.005, 0.002 and 0.001 mm. A constant axial force when the screw contacts the workpiece is provided by a friction ratchet device. When the measuring surfaces of the micrometer are in close contact with the surface of the measured part, the ratchet begins to turn with a slight crackle, while the rotation of the microscrew should be stopped after three clicks.

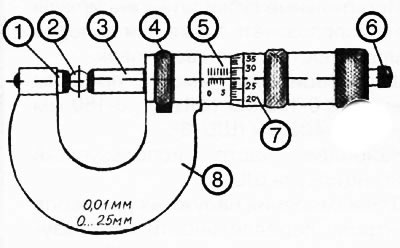

When taking measurements, the subject (2) clamped between the heel and the micrometer screw (3). On the surface of the stem there are two dashed scales, shifted relative to each other by 0.5 mm, and having a division value of 1 mm. Drum (7) rotates around a circular scale, which is also located on the bevel of the drum. The micrometer screw can be fixed in any position. The screw is equipped with a ratchet mechanism to ensure a constant measuring pressure.

1. Heel.

2. Subject of measurement.

3. Spindle.

4. Wheel.

5. Measuring scale (in mm).

6. Ratchet.

7. Nonius drum.

8. Staple.

1. The object is installed between the heel and the micrometer screw, while rotating the drum, set the spindle on the approximate size of the object.

2. The spindle is carefully approached until it touches the object to be measured.

3. The size in mm is determined using the vernier of the drum, which corresponds to the horizontal index stroke of the stem scale.

4. The total size of the measured object is determined.

Note. When in contact with the measured object, do not press the spindle by rotating the drum sleeve by hand, this can lead to breakage of the micrometer. For more accurate sizing, you need to make sure that the item is well fixed.