Attention. If the position of the engine support No. 3 during reinstallation differs from the original position, this will lead to increased noise and vibration of the engine. Before removing engine mount #3, make alignment marks on engine mount #3 to set the mount to the same position later.

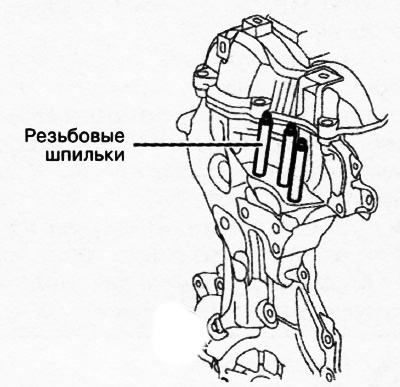

Note: If the #3 engine mount nuts are loose, the engine front cover threaded studs must be retightened as they may be the loose ones, not the nuts.

1. Tighten the threaded studs on the engine front cover to 40-52 Nm.

2. Tighten the gearbox studs to 15-25 Nm.

3. In reverse order, place the power unit under the vehicle's engine compartment, and then lower the vehicle on the lift.

4. Using an engine jack, raise the power package to the desired height.

5. Install bolts and nuts of #3 mount:

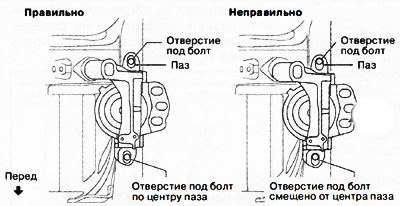

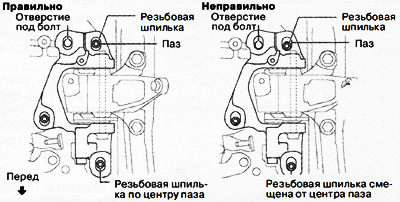

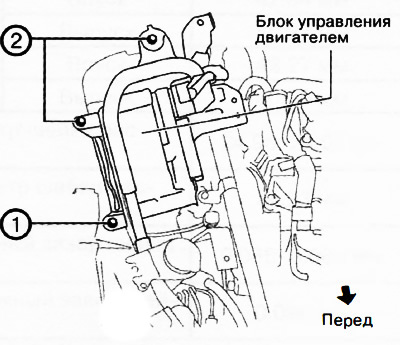

Install the bolts shown in the illustration to center the #3 engine mount mounting slots.

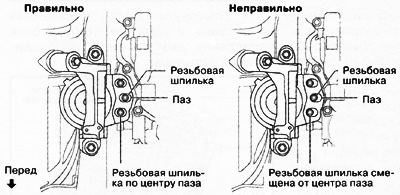

Install the nuts shown in the illustration to center the threaded studs on the engine front cover with the #3 engine mount mounting slots.

Note: If the threaded studs are off center of the slots, center them by moving the motor slightly, then tighten the set nuts.

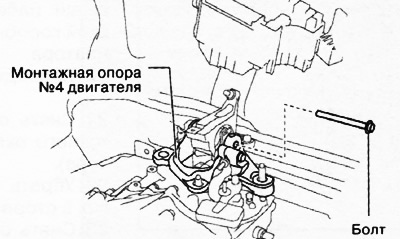

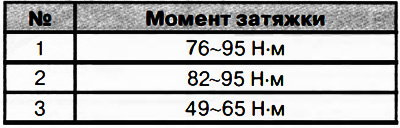

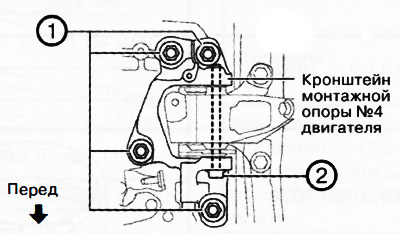

6. Install the #4 engine mount mounting bolts and nuts:

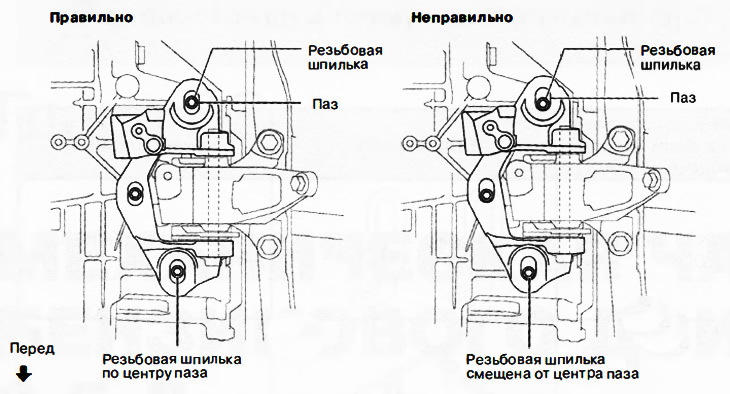

Fit the bolt shown in the picture.

Install the nuts shown in the illustration to center the #4 engine mount bracket slots.

Versions with manual transmission

Versions with automatic transmission

Note: If the threaded studs are off center of the slots, center them by moving the motor slightly, then tighten the set nuts.

7. Install front subframe with #1 engine mount pad (see chapter "Suspension").

8. Make the following parts:

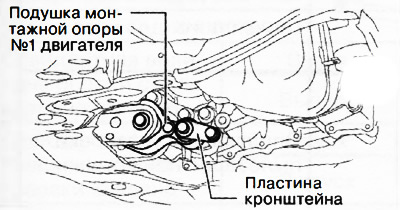

Versions with front wheel drive only (2WD): #1 engine mount bracket, #1 mount pad, and bracket plate.

Versions with all-wheel drive (4WD): #1 mount pad and bracket plate.

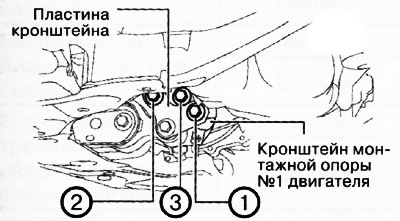

9. Versions with front wheel drive only (2WD): Tighten the No. 1 engine mount bracket and the bracket plate mounting bolts in the sequence shown in the figure to a torque of 131-153 Nm.

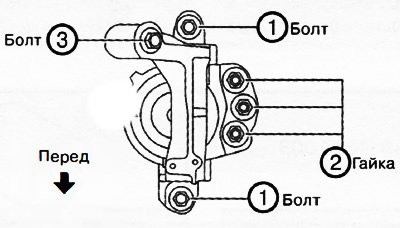

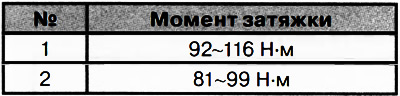

10. Tighten the #3 motor mount set bolts and nuts in the sequence shown in the illustration.

|  |

11. Tighten the #4 engine mount bracket set bolts and nuts in the sequence shown in the illustration.

Versions with manual transmission

Versions with automatic transmission

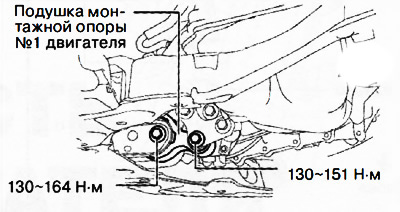

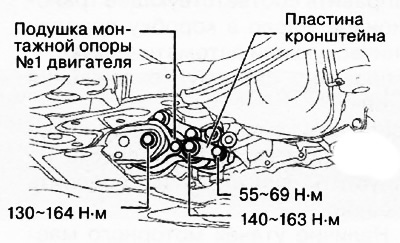

12. Tighten the #1 engine mount pad mounting bolts.

Versions with front wheel drive only (2WD)

Versions with all-wheel drive (4WD)

13. Install the sealing plate.

14. Install the wiring bracket, A/C hose and connector.

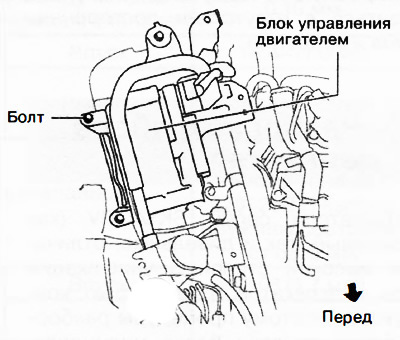

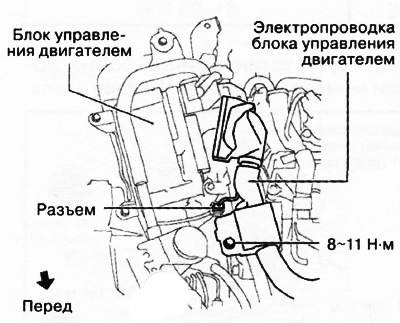

15. Install the electronic engine control unit:

Install the screws shown in the figure.

Tighten the bolts of the electronic engine control unit in the sequence shown in the figure with a tightening torque of 9-10 Nm.

Install the bolt and connector shown in the figure.

Connect the engine control unit connector (140 pins).

16. Fill the appropriate gear oil into the gearbox (mechanical or automatic).

17. Fill the engine cooling system.

18. Check vehicle wheel alignment (see chapter "Suspension").

19. Start the engine and check the following:

- Leaks in engine oil, coolant, transmission oil and fuel.

- Runout or snagging of pulleys and drive belts.

- idle frequency.

- Functioning of all engine components.

Note: After installing the engine on the vehicle, it is necessary to perform a test drive in order to make sure that there are no extraneous noises and vibrations.