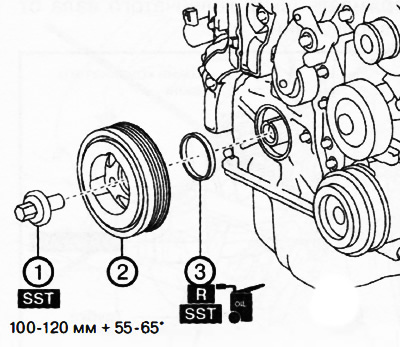

1. Crankshaft pulley bolt.

2. Crankshaft pulley.

3. Front crankshaft oil seal.

Note:

: replace the part with a new one after each removal.

: use a special tool or attachments.

: apply oil.

Attention. A hot engine can cause burns. Before starting work, turn off the engine and wait until it cools down.

1. Remove the front protective tray No. 2 of the engine.

2. Remove mudguard.

3. Remove the attachment drive belt.

Note: At least one other person is required to loosen the crankshaft pulley bolt.

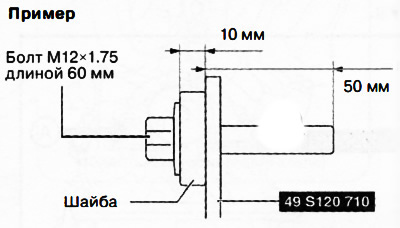

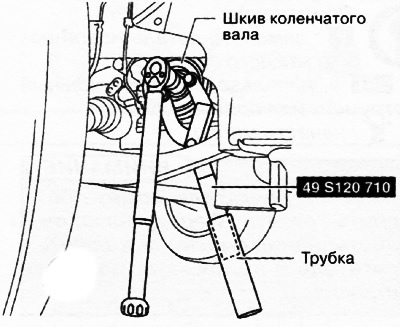

4. With bolts (M12x1.75 strength class 8.8 or higher, length 48-50 mm - length can be adjusted by adding washers) install a special tool on the crankshaft pulley. Tightening torque: 15 Nm.

Attention.

- To prevent damage to the crankshaft pulley and engine front cover, be sure to use bolts of the specified size and tighten them to the specified torque when installing the special tool on the crankshaft pulley.

- After installing the special tool, make sure that the bolts do not touch the engine front cover.

Note: If bolts with a length of 50mm or more are used, additional washers must be added to adjust the working length of the bolt to 48-50mm. So, to use M12x1.75 bolts with a length of 60 mm, which are supplied with special tool 49 S011 102A, you need to add a washer 10 mm thick.

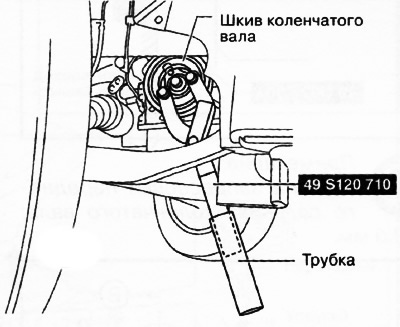

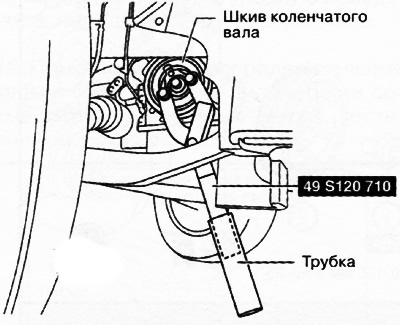

5. One person needs to connect the extension tube of suitable length (100 mm or more) to the special tool and hold the crankshaft pulley from turning.

6. The second person must unscrew and remove the crankshaft pulley bolt.

7. Remove the pulley from the crankshaft with the special tool.

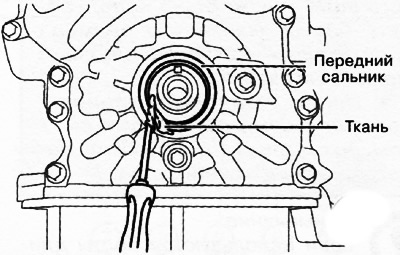

8. Cut off the edges of the gland with a regular knife.

9. Remove the oil seal using a flathead screwdriver wrapped in a clean cloth so as not to damage the surfaces of the crankshaft.

10. Apply clean engine oil to the inside surfaces of the new front crankshaft oil seal.

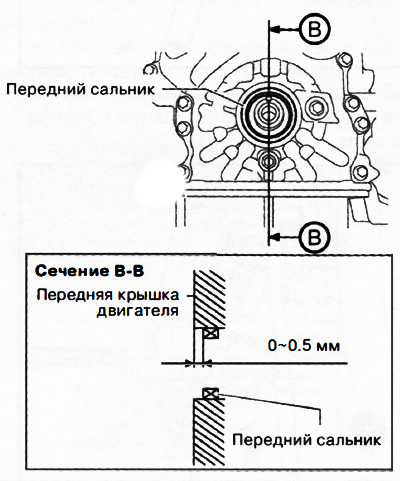

11. Manually insert the crankshaft front oil seal into the engine front cover.

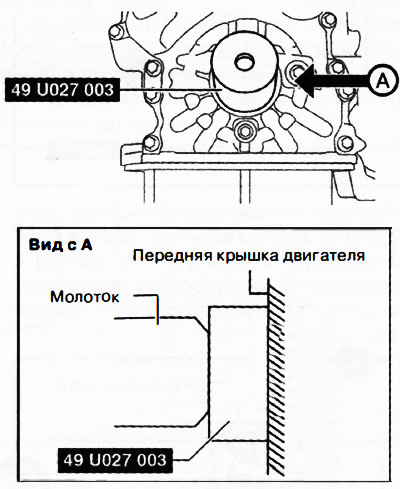

12. Press in the oil seal evenly using a suitable mandrel and hammer.

Note: Pressing depth of the crankshaft front oil seal: 0-0.5 mm.

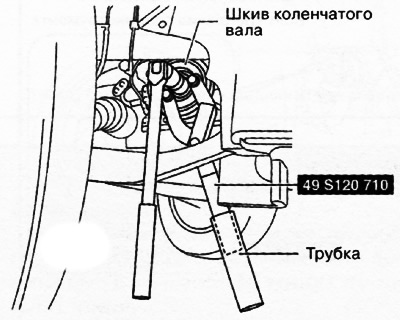

13. Install the pulley with the special tool on the crankshaft.

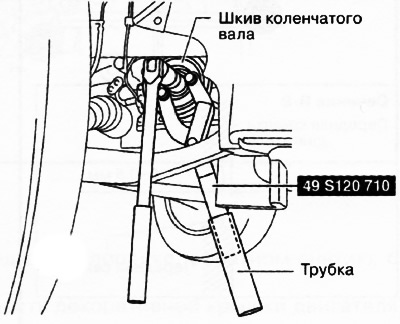

Note: The crankshaft pulley bolt must be tightened in two stages. For the second stage of tightening (stretching to a certain angle) helper needed.

14. Connect an extension tube of suitable length (100 mm or more) to the special tool and hold the crankshaft pulley from turning.

15. Tighten the crankshaft pulley bolt to 100-120 Nm.

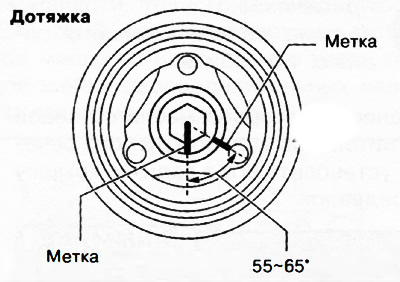

16. Use a marker to mark the bolt and crankshaft pulley as shown in the figure to tighten the bolt to the required angle.

17. While one person is holding the anti-rotation tool, the other should tighten the pulley bolt 55-65°.

|  |

18. Remove the special tool from the crankshaft pulley.

19. Further installation is carried out in the reverse order of removal.