Rotor

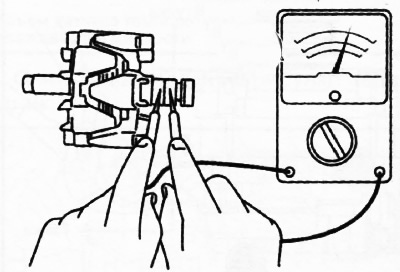

1. Using a tester, measure the resistance between slip rings. If the measured value is not correct (1.8-2.1 ohm at 20°C), replace the rotor with a new one.

2. Using a tester, make sure that there is no conductivity between the slip rings and the core. If the circuit is closed, replace the rotor with a new one.

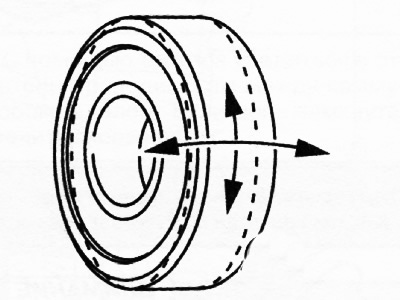

3. Check the condition of the surface of the slip rings. If the surface of the slip rings is rough, remove the defect with sandpaper.

Stator winding

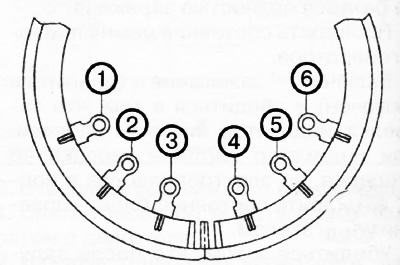

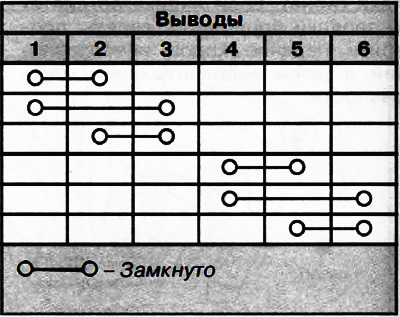

1. Check continuity between terminals according to the following table. If faults are found, replace the stator with a new one.

|  |

2. Using a tester, make sure that there is no conductivity between the stator winding leads and the core. If the circuit is closed, replace the stator with a new one.

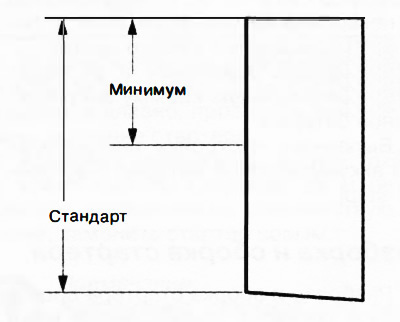

Brushes

1. Check brushes for wear. If any brush is worn to the limit or so, replace all brushes with new ones.

Note:

Brush length:

- Standard: 22.5 mm.

- Minimum: 5.0 mm.

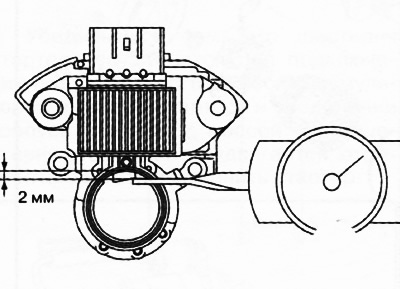

Brush springs

1. Using a dynamometer, measure the force of the brush springs.

2. Read off the spring pressure when the brush edge protrudes 2 mm. If the measured value is not correct, replace the brush spring with a new one.

Note:

Clamping force of brush springs:

- Standard: 4.1-5.3 N.

- Minimum: 1.7 N.

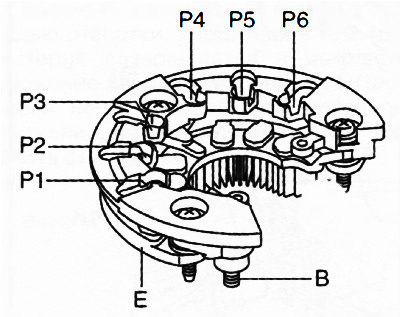

Rectifier

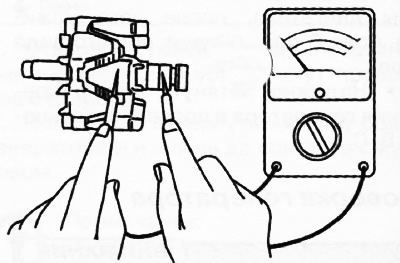

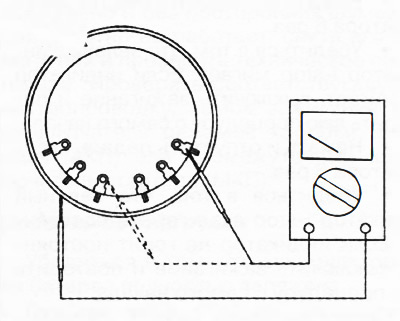

Check the conductivity of the diodes using an analog tester. If the test results are not correct, replace the rectifier with a new one.

Using an analog tester

Using a digital tester

Bearing

Check bearings for abnormal noise, looseness and jamming. If necessary, replace the bearing with a new one.