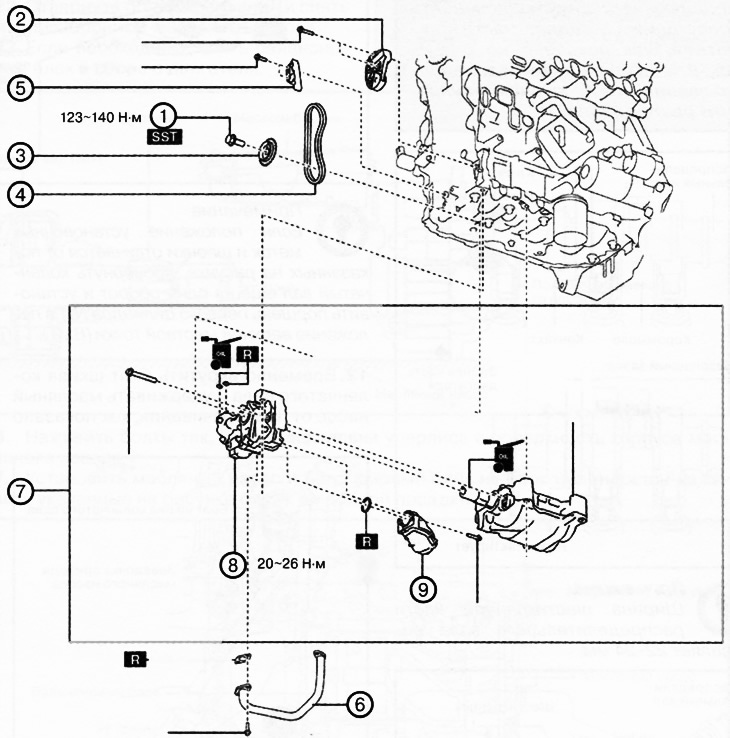

Removal and installation of the oil pump

Diesel engine:

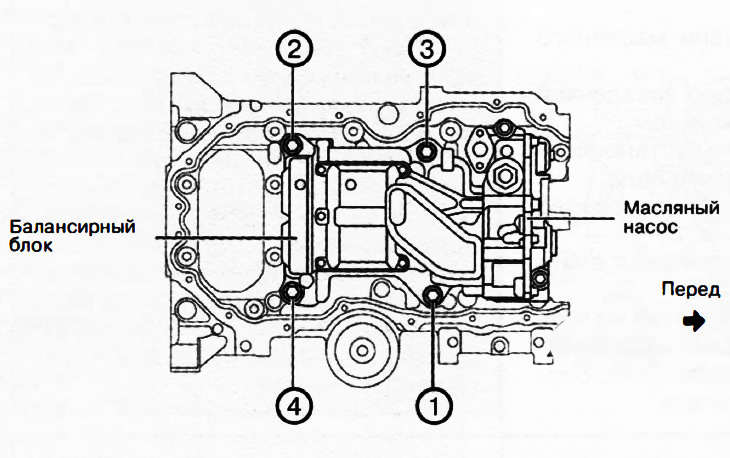

1. Oil pump sprocket bolt.

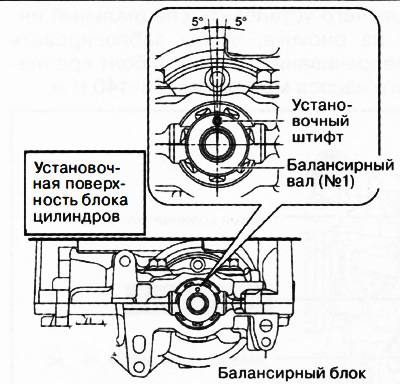

2. Oil pump drive chain tensioner.

3. Oil pump sprocket.

4. Oil pump drive chain.

5. Oil pump drive chain damper.

6. Oil pipe.

7. Balancing block assembly.

8. Oil pump.

9. Oil intake.

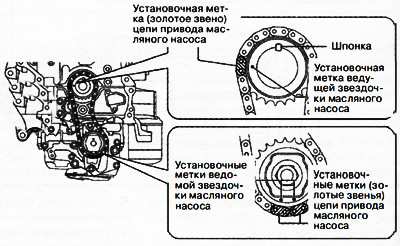

Note.

: replace the part with a new one after each removal.

: use a special tool or attachments.

: apply oil.

Attention.

- A hot engine and engine oil can cause various burns. You must turn off the engine and wait until it cools down.

- A vehicle that is raised on a lift but not secured with safety stands is dangerous. It may come off and fall, causing death or serious injury. Do not work around or under a raised vehicle that is not supported by safety stands.

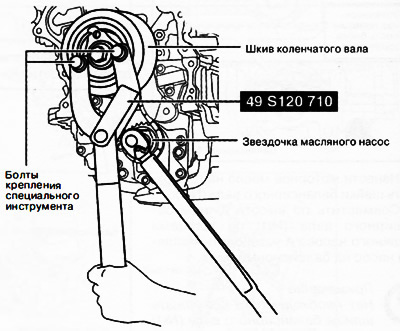

- Prolonged skin contact with used engine oil can cause skin cancer. Wash hands thoroughly with soap and water immediately after handling engine oil.

- If the camshaft is rotated after the timing chain has been removed, when the piston is at top dead center, the valves may hit the piston crown, causing engine damage. When rotating the camshaft with the drive chain removed, it is necessary to set all the engine pistons to the middle position.

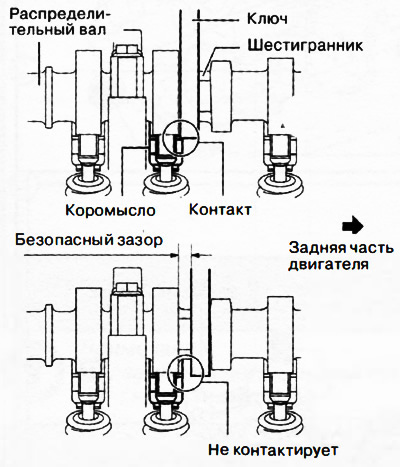

- When turning the camshaft with a wrench on the hex part, the wrench may rest against the rocker and damage it. To prevent damage to the rocker arm, when holding the camshaft by the hex part, place the wrench closer to the rear of the engine, as shown in the figure, to ensure a safe gap between the wrench and the camshaft cam.

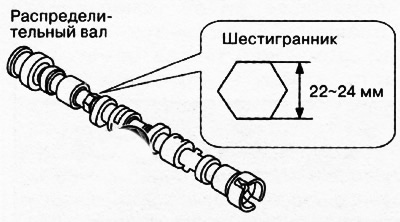

Note. The width of the hexagonal part of the camshaft is 22-24 mm.

Removing the oil pump

1. Disconnect the negative battery terminal.

2. Remove the decorative engine cover.

3. Remove the protective tray No. 2 of the engine.

4. Remove mudguard.

5. Remove the attachment drive belt.

6. Drain engine oil.

7. Remove the oil pan from the engine.

8. Remove fuel injectors.

9. Drain coolant.

10. Remove the timing chain (see chapter "The mechanical part of the diesel engine 2.2 l").

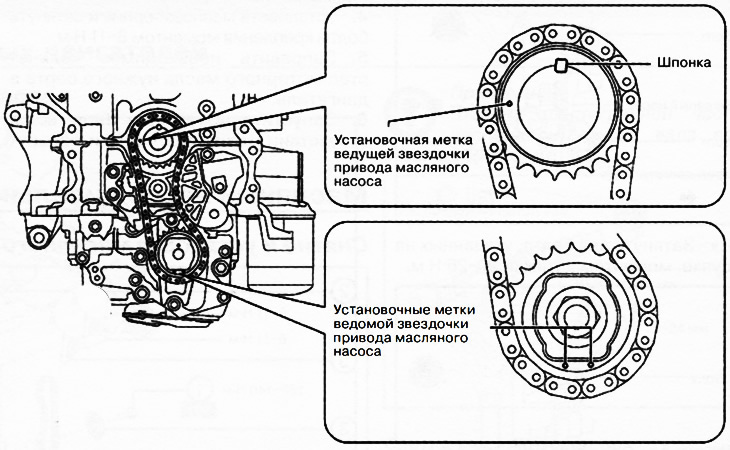

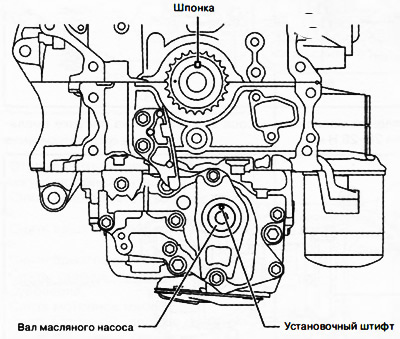

11. Make sure that the alignment marks of the oil pump drive sprocket and the key are in the positions shown in the figure.

Note. If the position of the alignment marks and the key differs from those shown in the figure, rotate the crankshaft one more turn and set the piston of the first cylinder No. 1 to the top dead center position (TDC).

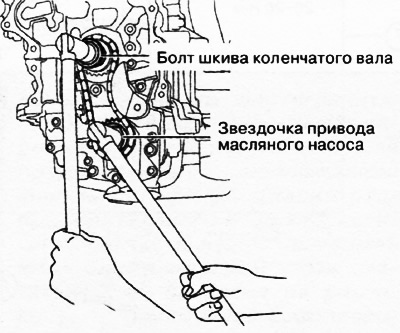

12. Temporarily screw in the crankshaft pulley bolt and hold the oil pump from turning as shown in the figure.

13. Loosen the oil pump sprocket bolt.

Note. At this stage, you only need to loosen the sprocket mounting bolt, but do not unscrew it completely. Remove the bolt after removing the oil pump drive chain tensioner.

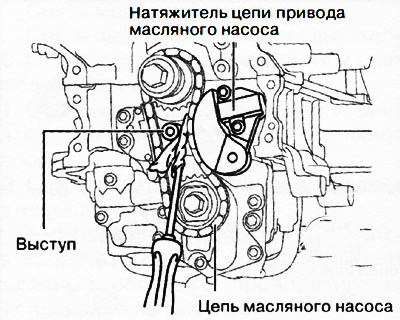

14. Insert a flat screwdriver wrapped with a cloth into the gap between the protrusion on the bottom of the cylinder block and the oil pump chain, as shown in the figure.

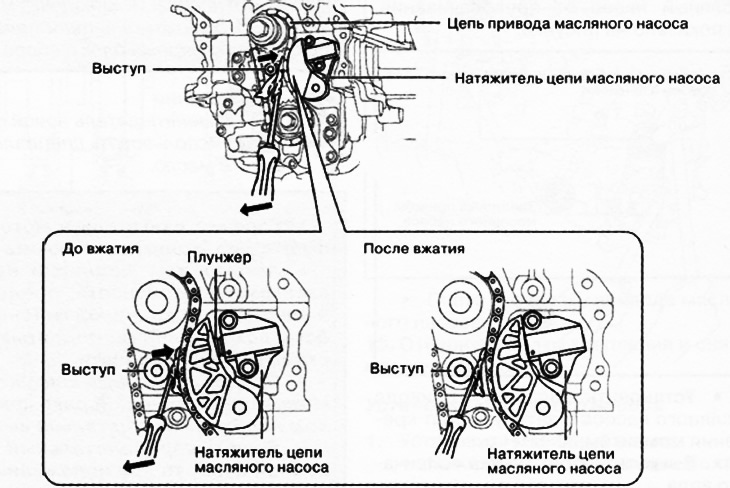

15. Moving the screwdriver in the direction of the arrow, press the oil pump drive chain and push in the oil pump drive chain tensioner plunger.

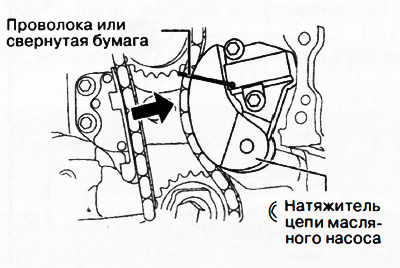

16. While pressing the plunger, insert a wire with a diameter of approximately 1.4 mm or folded paper into the hole in the oil pump chain tensioner housing.

Note. The wire or rolled paper will hold the plunger, which will relieve tension on the drive chain.

17. Remove the oil pump chain tensioner.

18. Remove the drive chain with the oil pump sprocket in one assembly.

19. Remove the temporarily installed crankshaft pulley bolt.

20. Remove the oil pump drive chain damper.

21. To turn away bolts of fastening and to remove an oil branch pipe.

22. Unscrew the mounting bolts and remove the oil intake from the oil pump.

23. If necessary, remove the balancing block assembly from the engine.

Oil pump installation

Attention.

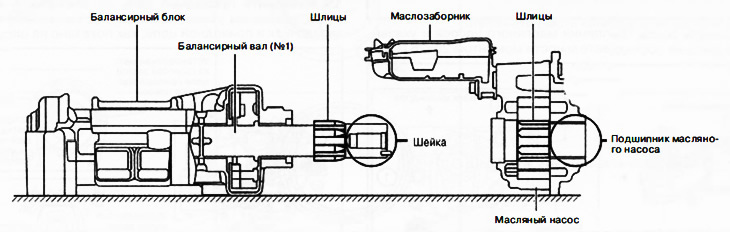

- If the balance shaft splines (№1) are damaged, the engagement with the oil pump gear will be broken and the installation of the oil pump may not be possible. Be careful not to damage the balancer shaft splines.

- Since the balance shaft journal (№1) rotates with the oil pump bearing, if the journal is damaged, the bearing may also be damaged. Be careful not to damage the balance shaft journal.

1. Apply clean engine oil to a new oil pickup O-ring.

2. Install the oil pickup on the oil pump.

3. Verify that the balance shaft dowel pin is (№1) located perpendicular to the mounting surface of the cylinder block. If the position of the dowel pin is different, by turning the balance shaft (№1), correct the position.

4. Apply engine oil to the surface of the journal of the balance shaft (№1).

5. Align the splines of the balance shaft (№1) with the oil pump splines and install the oil pump on the balancing block.

Note. No need to align balance shaft splines (№1) and the oil pump in some strictly defined position.

6. Screw on the bolts so that their heads rest against the surface of the oil pump housing.

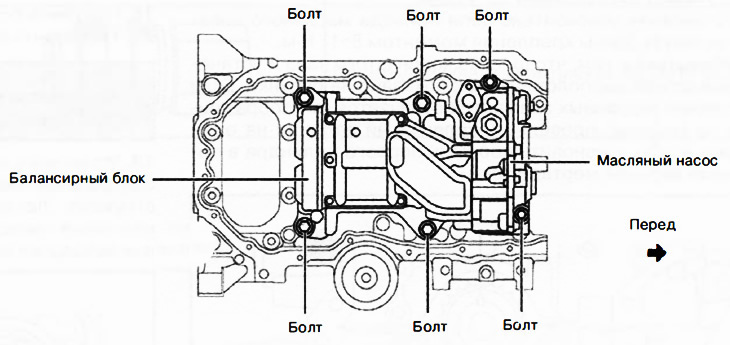

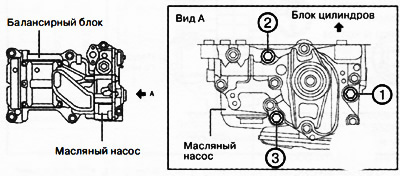

7. Install the oil pump and balancing block on the cylinder block and screw on the bolts shown in the figure until they are fully seated.

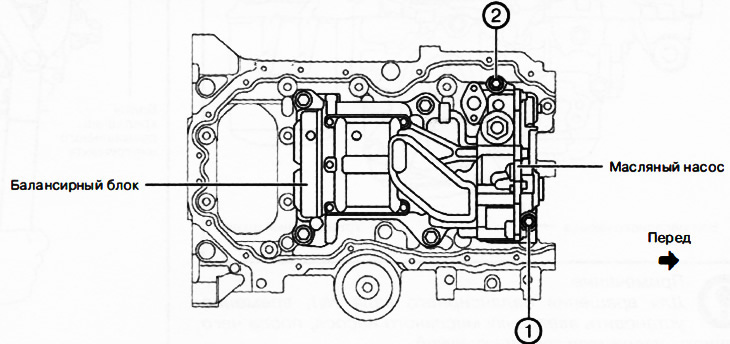

8. Tighten the oil pump mounting bolts in the sequence shown in the figure to a torque of 20-26 Nm.

9. Tighten the balancing block mounting bolts in two stages in the sequence shown in the figure:

- Stage 1: 16-22 Nm.

- Stage 2: 30-36 Nm.

10. Tighten the oil pump mounting bolts in the sequence shown in the figure to a torque of 20-26 Nm.

11. Install the oil pipe with new gaskets and tighten the mounting bolts 10-13 Nm.

12. Install the oil pump drive chain damper and tighten the mounting bolts to a torque of 8-11 Nm.

13. Verify that the crankshaft key and dowel pin are positioned as shown. If the position of the indicated elements differs from that shown in the figure, turn the crankshaft one more turn to set the piston of the first cylinder to the top dead center position.

Note. To rotate the #1 balance shaft, temporarily install the oil pump sprocket, then rotate while holding the sprocket with your hand.

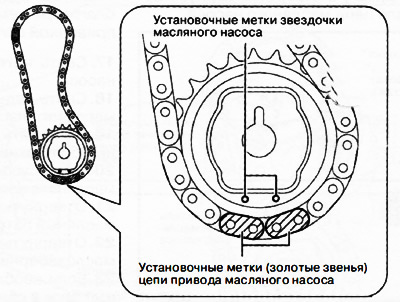

14. Align the timing marks on the drive chain with those on the oil pump sprocket.

15. Install the drive chain with the oil pump sprocket in one unit, aligning the alignment marks on the sprockets and the drive chain, as shown in the figure.

16. Fit the oil pump sprocket bolt.

17. Install the oil pump drive chain tensioner.

Attention. At this stage, do not remove the wire or rolled paper inserted into the tensioner body.

18. Install the crankshaft pulley and temporarily screw in the central bolt, then install the special tool shown in the figure to block the oil pump from turning. Tighten the oil pump sprocket bolt to 123-140 Nm.

19. Unscrew the temporarily installed central bolt and remove the pulley from the crankshaft. Remove the wire or folded paper inserted into the hole in the oil pump housing.

Note. If using a new drive chain tensioner, remove the installed retainer.

20. Install the remaining parts in the reverse order of removal.

21. Fill the required amount of engine oil of the correct grade into the engine.

22. Fill with coolant.

23. Check the tightness of the cooling system.

24. Start the engine and check:

- The presence of engine oil leaks.

- Engine oil level.

- Runout and grazing of pulleys and drive belt.

- Engine idle speed.