Attention.

- A hot engine and engine oil can cause various burns. You must turn off the engine and wait until it cools down.

- A vehicle that is raised on a lift but not secured with safety stands is dangerous. It may come off and fall, causing death or serious injury. Do not work around or under a raised vehicle that is not supported by safety stands.

- Prolonged skin contact with used engine oil can cause skin cancer. Wash hands thoroughly with soap and water immediately after handling engine oil.

Versions with petrol engine

1. Disconnect the negative battery terminal.

2. Remove the front protective tray #2.

3. Remove the oil pressure sensor.

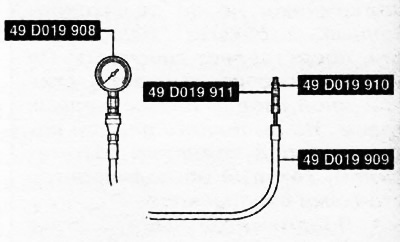

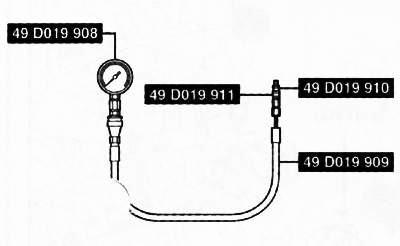

Note. Engine oil pressure is checked using pressure gauge 49 0019 908, hose 49 0019 909 and adapters 49 0019 910 and 49 0019 911.

4. Connect a pressure gauge with a hose to the oil pressure sensor mounting hole:

- Preassemble hose 49 0019 909, adapter 49 0019 911 and pressure gauge 49 0019 908 outside the engine compartment.

- Insert adapter 49 0019 910 into the mounting hole of the oil pressure switch.

- Connect adapter 49 0019 911 to adapter 49 0019 910.

5. Connect the negative battery terminal.

6. Warm up the engine to normal operating temperature.

7. Increasing the engine speed to the desired value, record the readings of the pressure gauge. If the values obtained are not correct, find out the cause and eliminate the malfunction by repair or replacement.

Note.

Oil pressure may vary depending on viscosity, temperature and engine speed.

Oil pressure (indicative value) at a coolant temperature of 80-90°C:

- Low (1 500 rpm): 110-175 kPa (1.13-1.78 kg/cm2).

- High (4 500 rpm): 300-430 kPa (3.06-4.38 kg/cm2).

8. Stop the engine and wait until it cools down.

9. Disconnect the negative battery terminal.

10. Remove pressure gauge with hose and adapters.

11. Install the oil pressure sensor.

12. Connect the negative plug of the storage battery.

13. Start the engine and check for oil leaks. If oil leaks are found, repair or replace the relevant component.

14. Install front skid plate #2.

Versions with diesel engine

Note. Engine oil pressure is checked using pressure gauge 49 0019 908, hose 49 0019 909 and adapters 49 0019 910 and 49 0019 911.

1. Disconnect the negative battery terminal.

2. Remove the expansion tank of the cooling system.

3. Disconnect the oil temperature/pressure sensor connector:

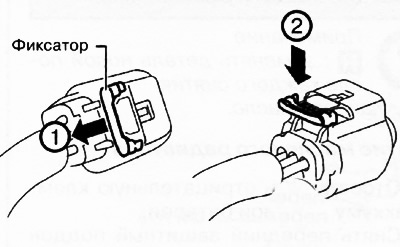

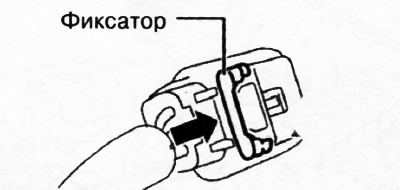

Pull out the connector lock in the direction of the arrow (1) on the image.

Pressing the latch down in the direction of the arrow (2), disconnect the connector.

4. Disconnect the starter terminal B and move the wire aside.

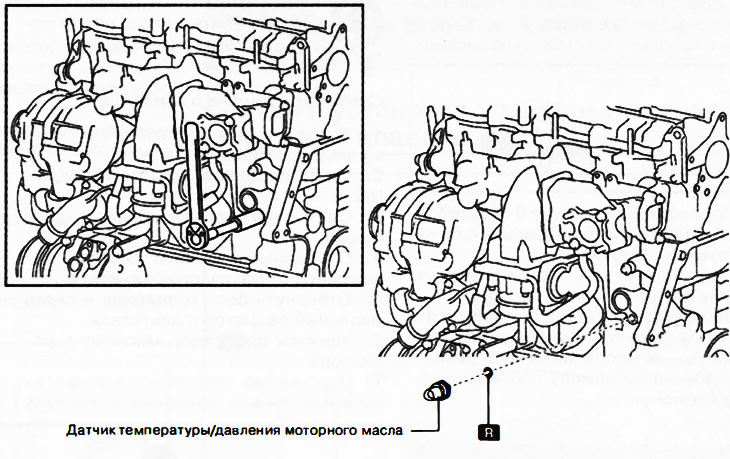

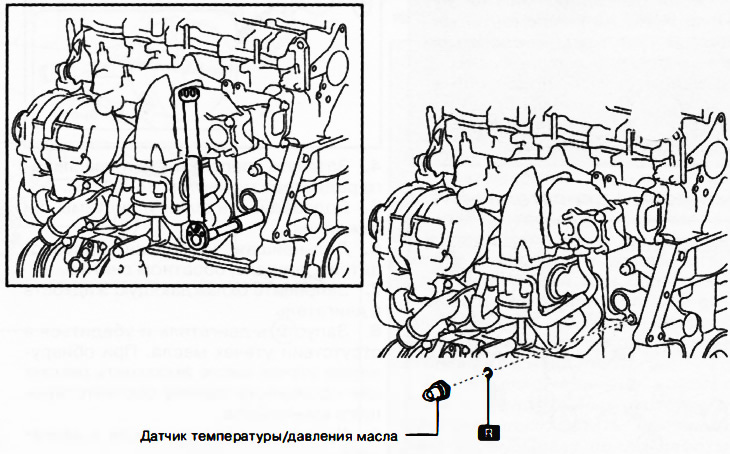

5. Remove the oil temperature sensor from the engine.

Note.: replace the part with a new one after each removal.

6. Connect a pressure gauge with a hose to the oil pressure sensor mounting hole:

- Preassemble hose 49 0019 909, adapter 49 0019 911 and pressure gauge 49 0019 908 outside the engine compartment.

- Insert adapter 49 0019 910 into the mounting hole of the oil pressure switch.

- Connect adapter 49 0019 911 to adapter 49 0019 910.

7. Connect terminal B of the starter.

8. Install the expansion tank of the cooling system.

9. Connect the negative battery terminal.

10. Warm up the engine to normal operating temperature.

11. Increasing the engine speed to the desired value, record the readings of the pressure gauge. If the values obtained are not correct, find out the cause and eliminate the malfunction by repair or replacement.

Note.

Oil pressure may vary depending on viscosity, temperature and engine speed.

Oil pressure (indicative value) at a coolant temperature of 80-90°C:

- Low (1 500 rpm): 140-190 kPa (1.43-1.93 kg/cm2).

- High (4 500 rpm): 300-440 kPa (3.06-4.48 kg/cm2).

12. Stop the engine and wait until it cools down.

13. Disconnect the negative battery terminal.

14. Remove the expansion tank of the cooling system.

15. Disconnect the starter terminal B and move the wire aside.

16. Remove pressure gauge with hose and adapters.

17. Install the oil pressure temperature sensor and tighten to 14-18 Nm.

Note.: replace the part with a new one after each removal.

18. Connect the oil temperature / pressure sensor connector and press the retainer in the direction of the arrow in the figure.

19. Connect terminal B of the starter.

20. Install the expansion tank of the cooling system.

21. Connect the negative battery terminal.

22. Start the engine and check for oil leaks. If oil leaks are found, repair or replace the relevant component.