Attention. If the piston is replaced with a new one, replace the piston, piston pin and circlips in one set.

1. Using a micrometer, measure the outer diameter of the piston 8 mm from the edge of the piston skirt (uncoated skirt area) in the direction of the stop.

Note: Standard piston outer diameter: 88.965-88.995 mm.

2. Measure the bore diameter of the cylinder.

3. Calculate the clearance between the piston and the cylinder by subtracting the piston diameter from the cylinder diameter. If the resulting gap exceeds the maximum allowable value, replace the piston or cylinder block.

Note:

- Standard clearance between piston and cylinder: 0.025-0.045 mm.

- Maximum allowable clearance between piston and cylinder: 0.066 mm.

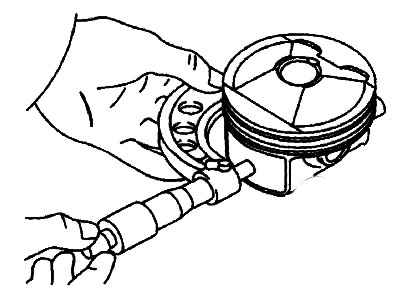

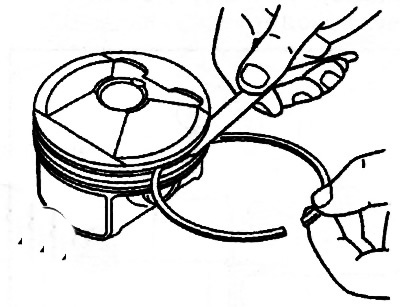

4. Using a set of flat feeler gauges, measure the backlash of the piston rings in the grooves around the piston. If the measured clearance is not correct, replace the piston or piston ring.

Note:

Standard backlash of piston rings in piston grooves:

- Top compression ring: 0.04-0.08mm.

- Second compression ring: 0.03-0.07 mm.

- Oil scraper ring: 0.04-0.12 mm.

Maximum permissible side clearance of piston rings in the piston grooves:

- Top compression ring: 0.12mm.

- Second compression ring: 0.10 mm.

- Oil scraper ring: 0.17 mm.