Attention. Do not disassemble the oil pump, water pump and balance block as they are precision units.

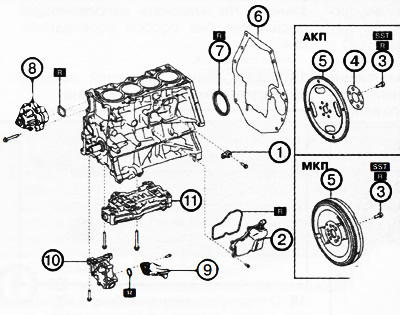

1. Knock sensor.

2. Oil separator.

3. Dual-mass flywheel mounting bolts (ITUC) /drive flange (AKP).

4. Platter (AKP).

5. Dual mass flywheel (ITUC) or drive flange (AKP).

6. End plate.

7. Rear crankshaft oil seal.

8. Water pump.

9. Oil intake with strainer.

10. Oil pump.

11. Balancing block.

Note:

: replace the part with a new one after each removal.

: use a special tool or attachments.

1. Remove the engine from the car.

2. Remove the attachment drive belts, as well as the timing and oil pump drive chains.

3. Remove the cylinder head and oil pan from the engine.

4. Unscrew the fastening bolt and remove the knock sensor.

5. To turn away bolts of fastening and to remove an oil separator.

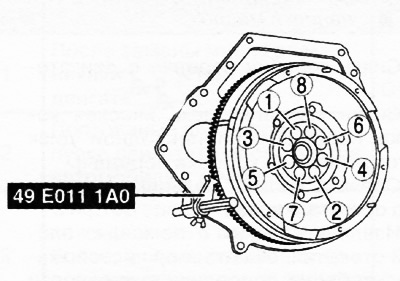

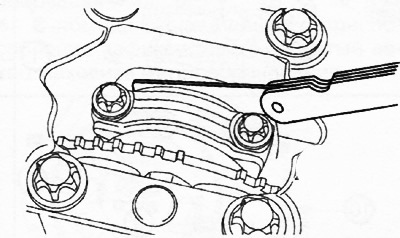

6. Fix the flywheel/drive flange ring gear with the special tool as shown.

7. Gradually unscrew the bolts in the sequence shown in the figure and remove the dual-mass flywheel (ITUC) or drive flange with platter (AKP).

8. Remove the end plate from the engine block.

9. To take a back epiploon of a cranked shaft.

10. To turn away bolts of fastening and to remove the water pump from the block of cylinders of the engine.

11. Remove the oil intake and oil pump from the engine block.

12. Unscrew the fastening bolts and remove the balancing block.

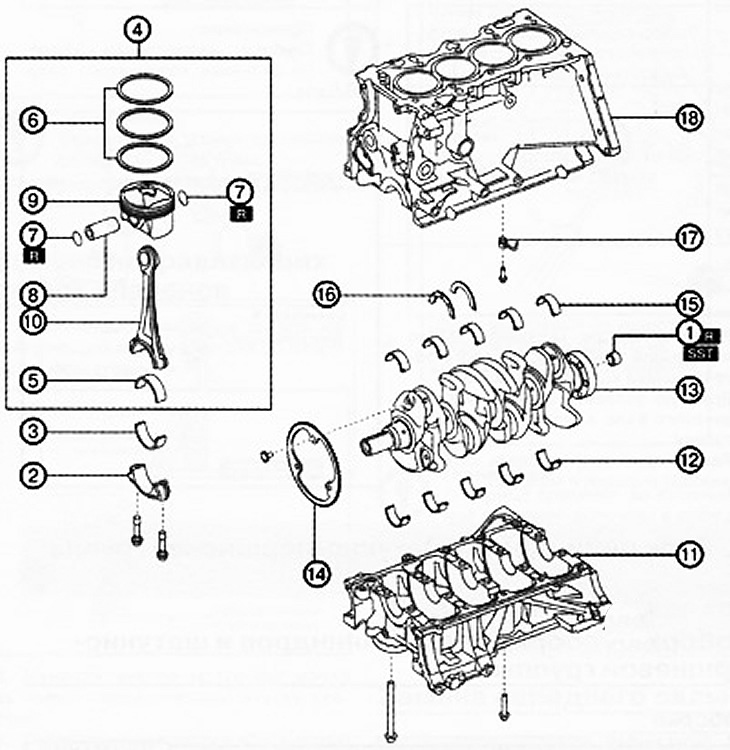

1. guide bearing (versions with MCP).

2. Connecting rod cap.

3. Lower connecting rod bearing.

4. Piston with connecting rod assembly.

5. Upper connecting rod bearing.

6. Piston rings.

7. Retaining rings.

8. Piston pin.

9. Piston.

10. Connecting rod.

11. The lower part of the cylinder block.

12. The lower shells of the main bearings of the crankshaft.

13. Crankshaft.

14. Impulse disk.

15. Upper shells of main bearings of the crankshaft.

16. Thrust half rings.

17. Oil nozzle.

18. Cylinder block.

Note:

: replace the part with a new one after each removal.

: use a special tool or attachments.

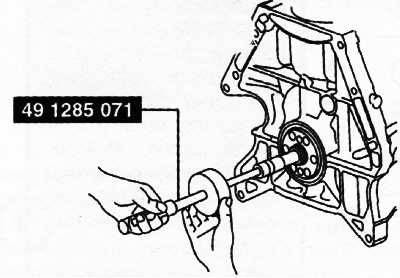

13. Versions with manual transmission: if necessary, use the special tool to remove the pilot bearing from the crankshaft.

Note: The pilot bearing should only be removed for replacement. Do not remove the pilot bearing unless absolutely necessary.

14. Before removing the connecting rod cover, check the side clearance of the connecting rod.

15. Unscrew the connecting rod bolts and remove the connecting rod caps. Position the removed connecting rod caps in the correct order for the engine cylinders and in the correct direction.

16. Remove the lower connecting rod bearings from the connecting rod caps and arrange in the appropriate order and direction.

17. Remove carbon from the top of the cylinder.

Note: Before removing the piston with connecting rod from the engine, check the oil clearance in the connecting rod bearing (see related section below).

18. Remove the piston and connecting rod assembly through the top of the cylinder.

19. Remove the upper connecting rod bearings and arrange in the appropriate order and direction.

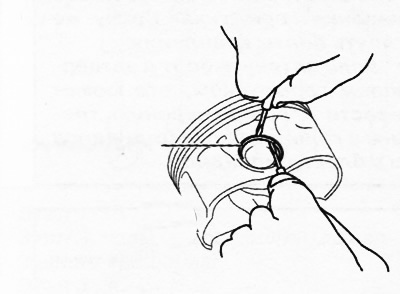

20. Using special pliers, remove the piston rings from the piston.

21. Verify that the bottom of the connecting rod falls freely under its own weight without resistance when the piston is turned.

22. Using flat screwdrivers, remove the circlips.

23. Remove the piston pin from the piston and separate the piston and connecting rod.

Note: Before removing the lower part of the cylinder block, check the end play of the crankshaft (see related section below).

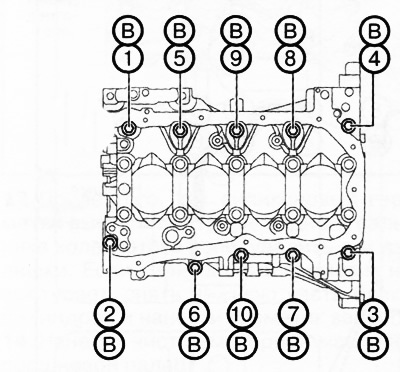

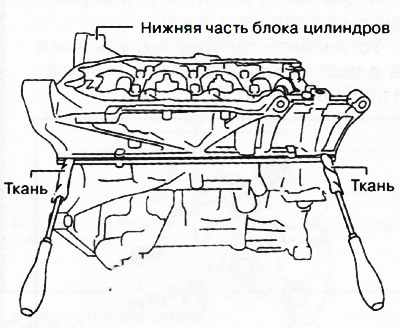

24. Loosen bolts B fastening the lower part of the cylinder block in two or three approaches in the sequence shown in the figure.

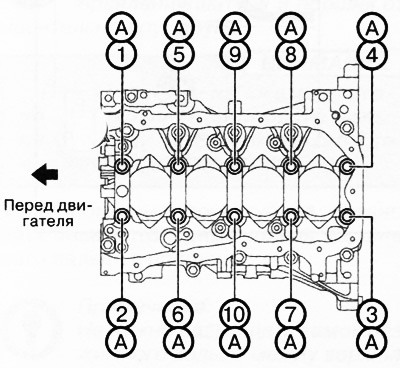

25. Loosen the bolts A of the lower part of the cylinder block in two or three approaches in the sequence shown in the figure.

26. Using a screwdriver wrapped in a cloth, gradually separate the sealant and remove the lower part of the cylinder block.

Attention.

- Do not apply excessive force to the screwdriver. Otherwise, the lower part of the cylinder block may be damaged.

- Be careful not to scratch or damage the seal surfaces. Otherwise, oil leaks may occur.

27. To take the lower loose leaves of main bearings of a cranked shaft from the bottom part of the block of cylinders and to arrange in the corresponding order and direction.

28. Remove the crankshaft from the engine block.

Attention. Do not place the crankshaft on a flat surface, as the diameter of the impulse disk mounted on the crankshaft is larger than the size of the crankshaft balancers. Place wooden blocks or other suitable objects under both ends of the crankshaft so that the impulse disk does not directly touch a flat surface.

29. If necessary, unscrew the mounting bolts and remove the impulse disk from the crankshaft.

30. To take the top loose leaves of main bearings of a cranked shaft and persistent half rings from the block of cylinders and to arrange in the corresponding order and direction.

31. Unscrew the mounting bolts and remove the oil nozzles from the cylinder block.