Replacing the valve body seal

1. Disconnect the negative battery terminal.

2. Remove the engine air filter.

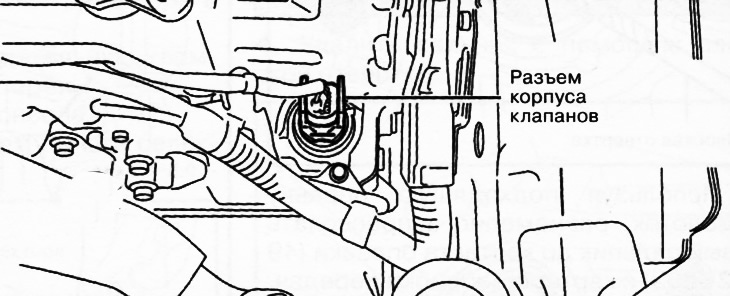

3. Disconnect the valve body connector.

Attention.

- Be careful not to touch the terminals of the connector with your hands, as this may damage the terminals.

- Water or foreign objects entering the connector can cause poor connections and corrosion. When disconnecting the connector, make sure that water and foreign objects do not get into it.

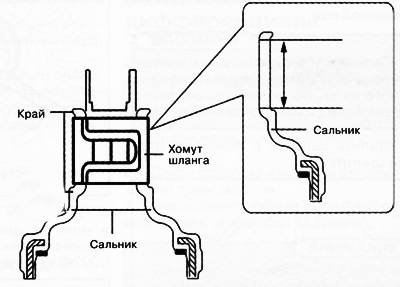

4. Remove the hose clamp.

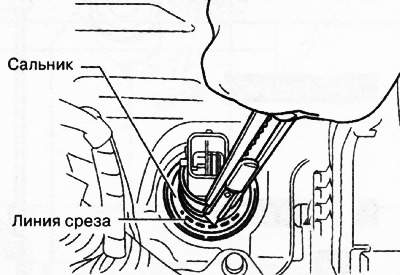

5. Cut off the oil seal with a knife as shown.

Attention.

- Take care not to damage the gearbox housing and the valve body connector.

- To prevent foreign material from entering the gearbox, thoroughly clean the oil seal installation area and cut off the oil seal without leaving any fragments.

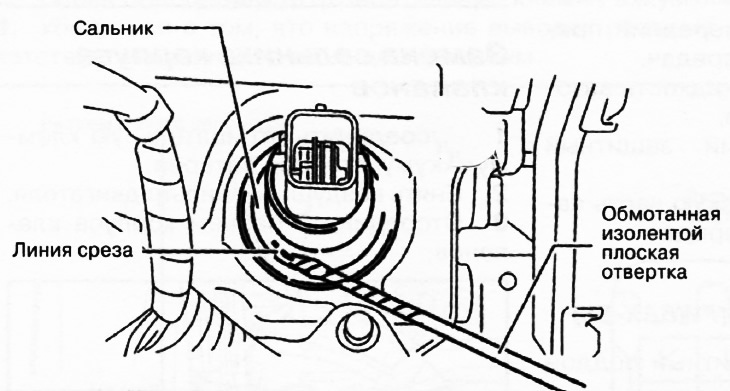

6. Using a flathead screwdriver wrapped with electrical tape, remove the oil seal from the gearbox housing.

Note. Remove the oil seal by tapping the tip of a tape-wrapped flathead screwdriver against the inner circumference of surface A of the oil seal.

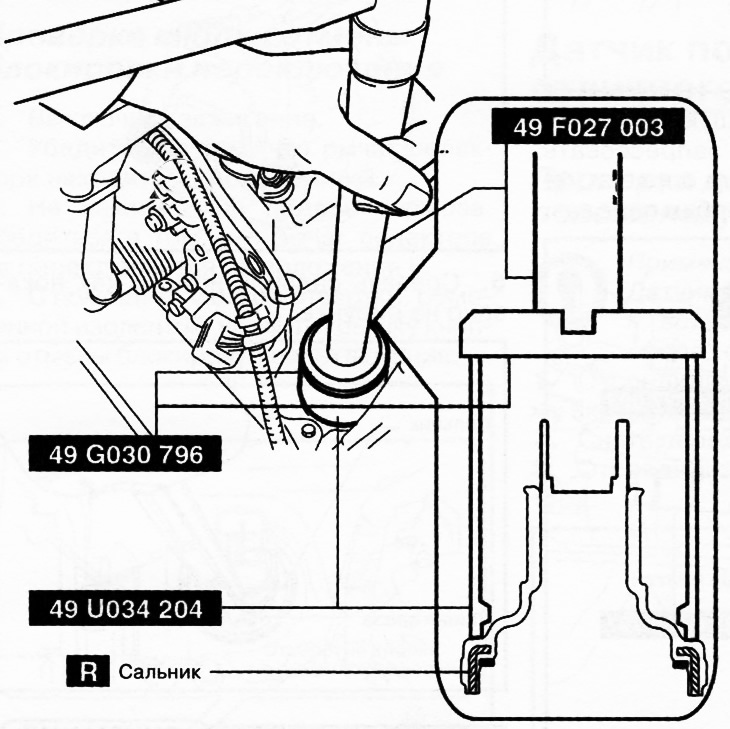

7. Screw on the valve body seal by hand.

8. Using a suitable mandrel and hammer, press in the valve body oil seal without distortion flush with the surface of the gearbox housing.

Note:replace the part with a new one after each removal.

Attention. When pressing in the valve body seal, care must be taken not to erroneously hit the valve body connector with a hammer. This can damage the connector, violating its tightness.

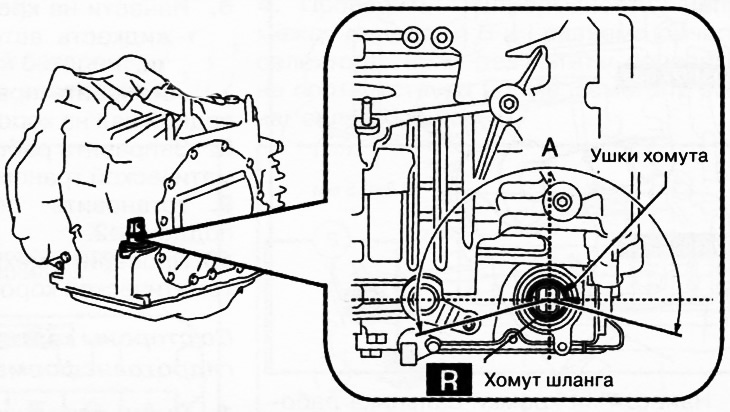

9. Install a new hose clamp in the position shown in the illustration.

Range A: 210°.

Note:replace the part with a new one after each removal.

Attention.

- Reusing a hose clamp can cause automatic transmission fluid leaks, so only a new hose clamp should be used.

- Install the lugs of the hose clamp so that they are in the range A shown in the figure.

- Install the hose clamp so that it does not snag on the top and bottom edges of the stuffing box to ensure proper tightness.

10. Connect the valve body connector.

Attention.

- Be careful not to touch the terminals of the connector with your hands, as this may damage the terminals.

- Water or foreign objects entering the connector can cause poor connections and corrosion. When disconnecting the connector, make sure that water and foreign objects do not get into it.

- Insert the connector straight so as not to damage its pins.

- Turn the connector lever until it clicks.

11. Install the engine air filter.

12. Connect the negative battery terminal.