Checking the clutch release bearing

Attention. Do not use cleaning agents or a steam cleaner to clean the clutch release bearing as the bearing is filled with grease.

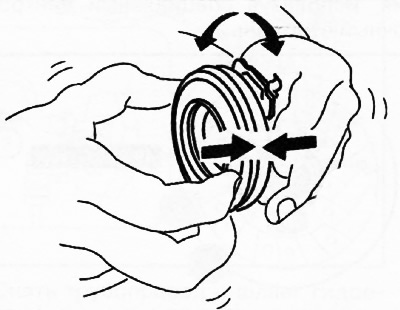

1. Squeezing the release bearing on both sides, turn it and check for wedging, excessive resistance and extraneous noise.

2. If any faults are found, replace the clutch release bearing with a new one.

Checking the clutch basket

1. Remove the clutch basket.

2. To check the clutch basket, do the following:

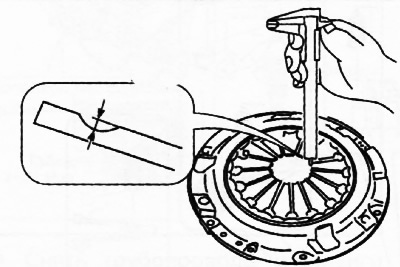

Measure the wear on the diaphragm spring petals. If the measured value is greater than 0.6 mm, replace the clutch basket.

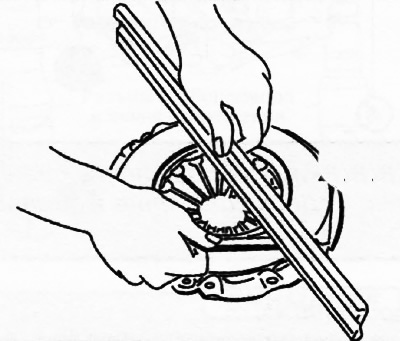

Measure the flatness of the pressure plate using a straightedge and a set of flat feeler gauges. The gap between the surface of the pressure plate and the straightedge should not exceed 0.3 mm.

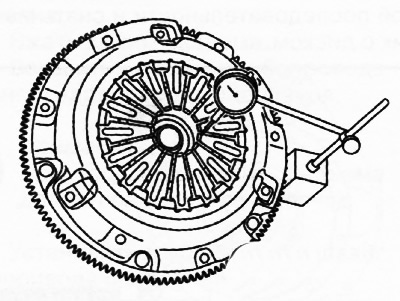

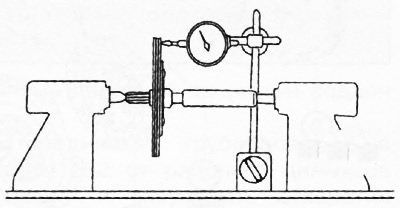

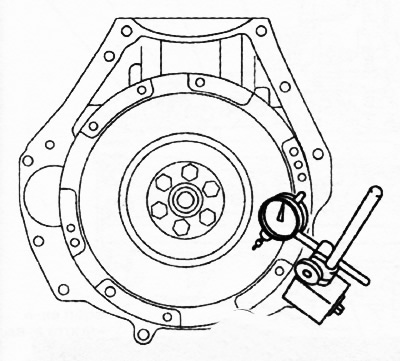

Check the uneven height of the diaphragm spring petals. To do this, install the clutch basket and place the dial indicator on the cylinder block as shown in the figure. Rotating the flywheel, check the discrepancy in height of the petals of the diaphragm spring. The difference in the height of the petals of the diaphragm spring should not exceed 0.1mm.

Checking the clutch disc

1. Check friction lining surface for discoloration and grease.

2. Check the wear of the torsion springs and the loosening of the friction lining rivets.

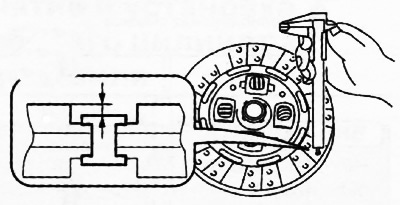

3. Using a vernier caliper, measure the depth of the rivets in the friction linings of the clutch disc. If the measured rivet depth is less than 0.3 mm, replace the clutch disc with a new one.

4. Using a dial gauge, measure the runout of the clutch disc. If the measured value is greater than 0.7 mm, replace the clutch disc with a new one.

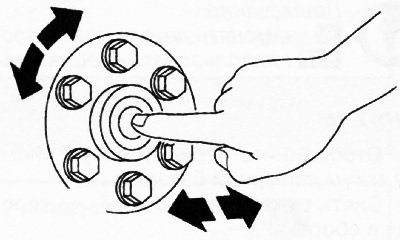

Checking the guide bearing

Without removing the guide bearing, turn it with your finger, pressing in the axial direction. If any defects are found (jamming, the presence of extraneous noise, etc.) replace the guide bearing with a new one.

Flywheel check

1. Remove the flywheel.

2. Perform the following procedures to check the flywheel:

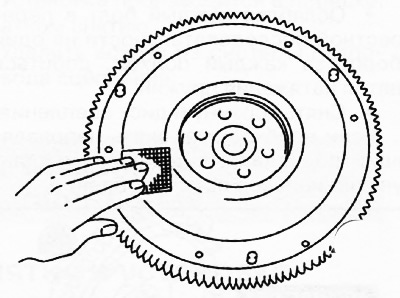

Check the contact surface of the flywheel with the clutch for scratches, dents and discoloration. Minor scratches and discoloration can be removed with sandpaper.

Check the flywheel ring gear for damage and wear.

Check the runout of the contact surface of the flywheel with the clutch disc. To do this, place a dial indicator on the installed flywheel, as shown in the figure, and, by rotating the flywheel, measure the amount of runout. The maximum allowable value of the flywheel runout: 0.1 mm.

If any unrecoverable defects are found, replace the flywheel with a new one.