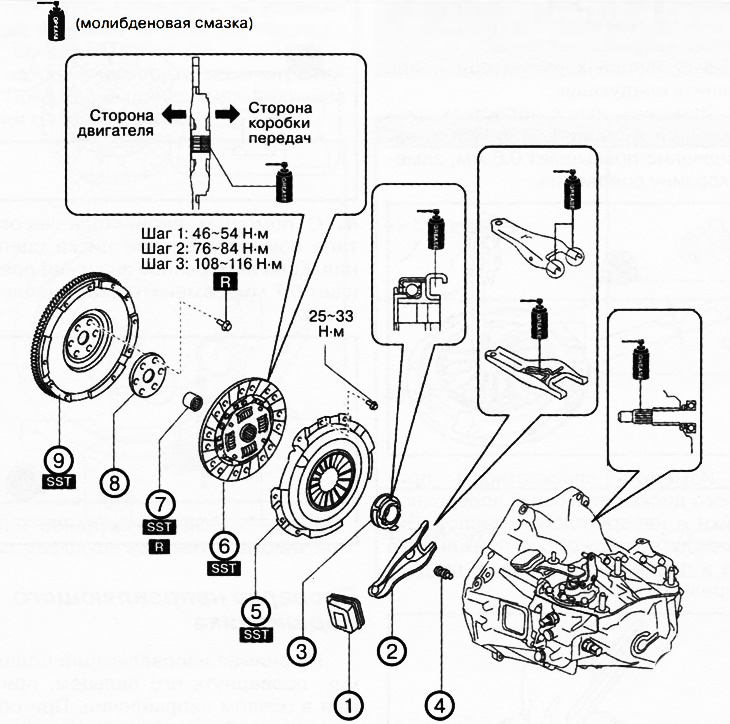

Note: Removal and installation of the clutch mechanism is shown using the C66M-R, C66MX-R clutch as an example.

1. Anther.

2. Clutch release fork.

3. Clutch release bearing.

4. Support pin.

5. Clutch basket.

6. Clutch disc.

7. Guide bearing.

8. Disk.

9. Flywheel.

Note:

: replace the part with a new one after each removal.

: use a special tool or attachments.

Removing

1. Disconnect the negative battery terminal.

2. Remove the manual transmission assembly.

3. Remove basket and clutch disc:

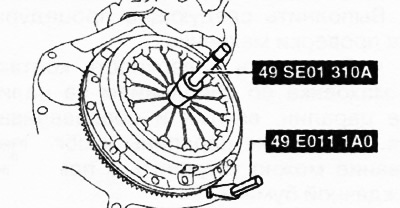

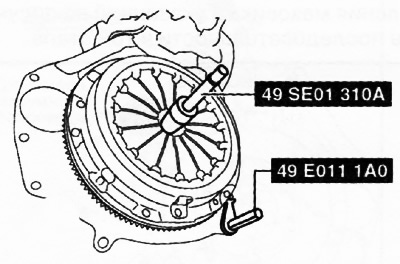

Using a special tool, fix the clutch mechanism.

Loosen each bolt in a criss-cross pattern one turn per set to release the tension on the springs.

Remove basket and clutch disc.

4. If necessary, remove the clutch guide bearing using the special tool.

Note: The pilot bearing should only be removed for replacement.

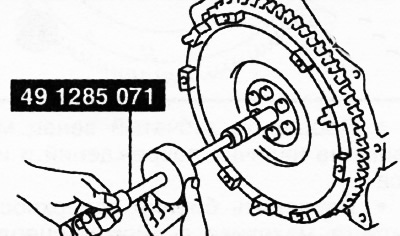

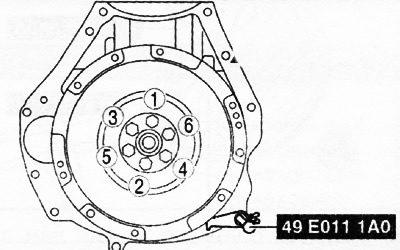

5. Remove the flywheel:

After fixing the flywheel with a special tool, unscrew the mounting bolts in the sequence indicated and remove the flywheel with the disk.

Check for leaks at the crankshaft rear oil seal. If necessary, replace the crankshaft rear oil seal with a new one.

Installation

1. Install the flywheel:

- Clean the threaded holes in the crankshaft.

- Install the flywheel with disc on the crankshaft and install new bolts.

- Fix the flywheel with the special tool.

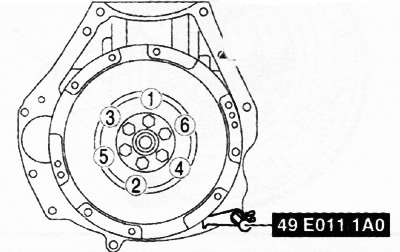

Fully tighten the flywheel mounting bolts in the sequence shown in the figure in three stages.

Flywheel bolt tightening:

- Stage 1: 46-54 Nm

- Stage 2: 76-84 Nm

- Stage 3: 108-116 Nm.

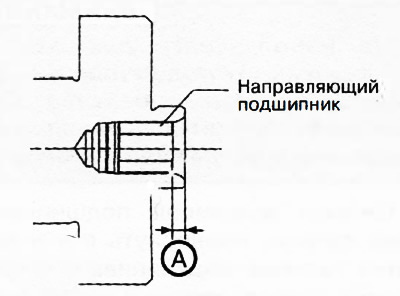

2. If it was removed, install a new clutch pilot bearing in the desired position using the adapter A160M7 (20-22 mm) from the A160M kit. To do this, position the 20 mm side of the adapter A160M7 to the pilot bearing. In addition, you can use any other mandrel or socket nozzle with an outer diameter of 21 mm and an inner diameter of 19 mm.

Note: Distance A to the guide bearing from the end of the crankshaft: 1.5-2.5 mm.

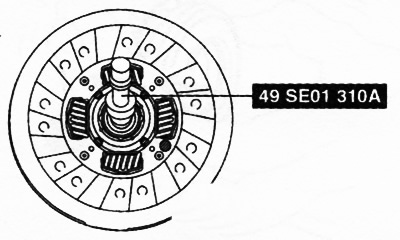

3. Install the clutch disc and basket using the special centering rod.

4. Fix the clutch mechanism from turning using a special tool.

5. Tighten the bolts in at least two passes:

Install the bolts in the sequence shown in the figure.

Fully tighten the bolts in the sequence shown in the figure to a torque of 25-33 Nm

6. Remove special tools.

7. Further installation is carried out in the reverse order of removal. After installation, fill the required amount of gear oil into the gearbox.