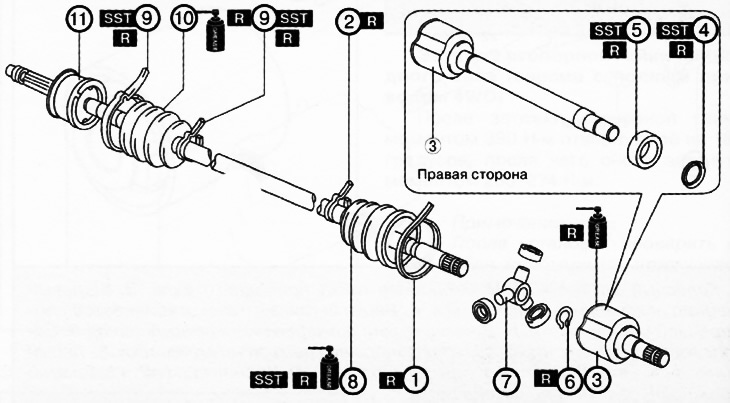

1. Large diameter boot collar (from the gearbox side).

2. Small diameter boot collar (from the gearbox side).

3. Outer ring.

4. Dust ring (if equipped).

5. Bearing.

6. Retaining ring.

7. Tripod.

8. Boot from the side of the gearbox.

9. Bellow collar (from the side of the wheel).

10. Boot from the side of the wheel.

11. Shaft with ball joint.

Note:

: replace the part with a new one after each removal.

: use a special tool or attachments.

: apply lubricant.

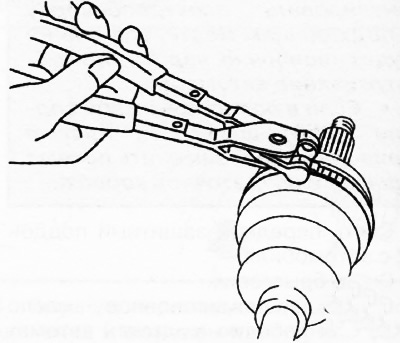

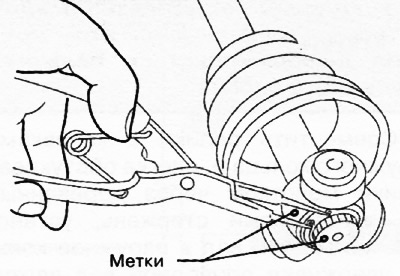

1. Using pliers, pry off the anther collar at the points indicated in the figure and remove the large diameter collar from the anther on the gearbox side.

Note: The small diameter dust collar can only be removed if it is damaged.

2. Remove the small diameter anther clamp using special pliers.

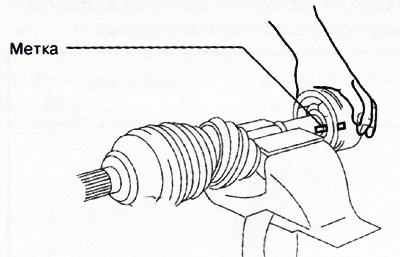

3. Mark the position of the outer ring in relation to the shaft for correct assembly later.

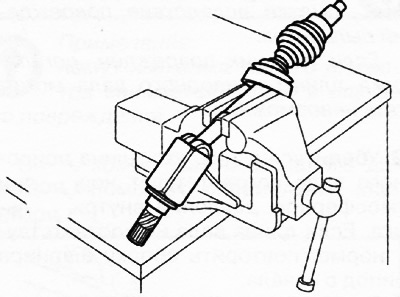

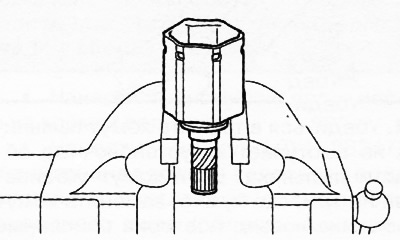

4. Fix the drive shaft in a vise.

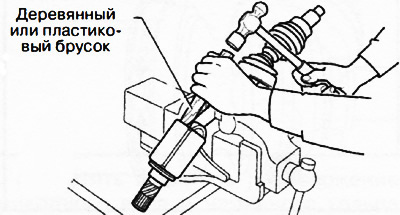

5. Tap the outer race lightly with a hammer through a block of wood or plastic, then remove the outer race from the drive shaft.

Attention. Be careful when hitting the outer ring, otherwise there is a risk of damage to the tripod hinge rollers.

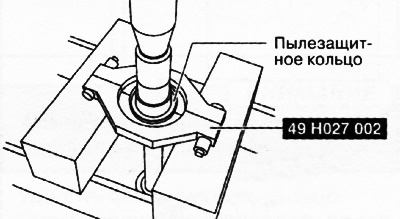

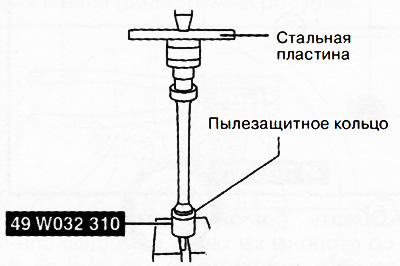

6. If equipped, remove the dust ring using a press and tool.

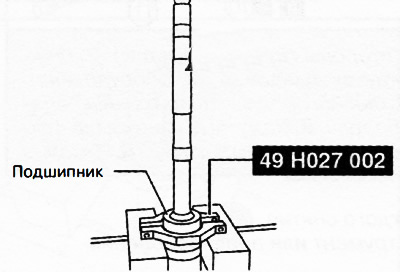

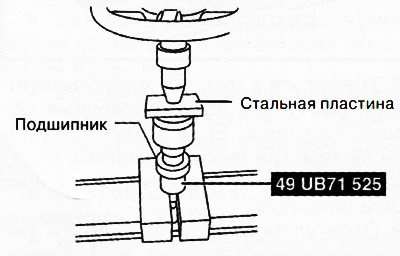

7. Remove the bearing from the drive shaft using a press and a special tool.

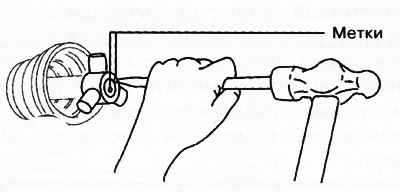

8. Put alignment marks on the shaft and hinge of the Tripod.

9. Using special pliers, remove the retaining ring.

10. Remove the Tripod hinge from the shaft.

Attention. Do not attempt to knock the Tripod hinge off the shaft with a hammer. This can damage the Tripod hinge.

Note: Remove the boot from the wheel side only in the event of a malfunction.

11. Wrap the splines of the shaft with electrical tape.

12. Remove the clamps and remove the boot from the side of the wheel from the shaft.

Note: The driveshaft boot on the wheel side and the gearbox side are different. Be careful not to mix up the anthers during installation.

13. Lay grease inside the new boot from the wheel side.

Note:

Do not touch lubricant with hands. Apply grease through a grease gun to prevent foreign material from entering the boot.

Amount of lubricant:

- SKYACT/VG 2.0 petrol engine: 96-106

- Diesel engine SKYACT/VD 2.2: 160-180 g.

14. After making sure that the splines of the shaft are still wrapped with electrical tape, install the boot on the drive shaft.

15. Remove tape from shaft splines.

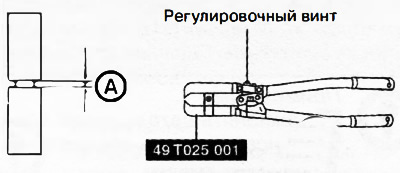

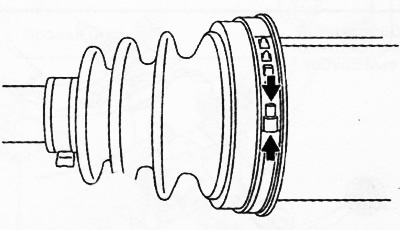

16. Adjust gap A to 2.9 mm by turning the adjusting screw of the special crimping tool.

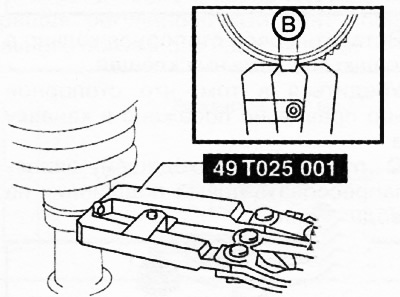

17. Compress the small collar of the anther from the side of the wheel using a special tool. Make sure gap B is correct (2.4-2.8mm). If gap B exceeds the allowable range, reduce gap A on the crimping tool and crimp the clamp again. If gap B is less than normal, replace the boot collar with a new one, increase gap A on the crimping tool, and crimp the new collar.

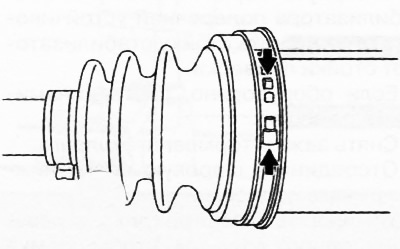

18. Make sure that the boot collar does not protrude beyond the boot mounting areas. If the clamp is not in the correct position, replace the boot clamp with a new one by repeating the above steps.

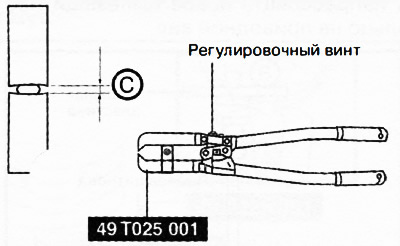

19. Adjust gap C to 3.2 mm by turning the adjusting screw of the special crimping tool.

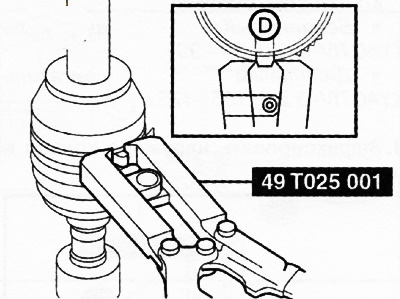

20. Crimp the large boot collar on the wheel side with the special tool. Make sure clearance D is correct (2.4-2.8mm). If gap D exceeds the allowable range, reduce gap C on the crimping tool and crimp the clamp again. If gap D is less than normal, replace the boot collar with a new one, increase gap C on the crimping tool and crimp the new collar.

21. Make sure the boot collar does not protrude beyond the boot mounting areas. If the clamp is not in the correct position, replace the boot clamp with a new one by repeating the above steps.

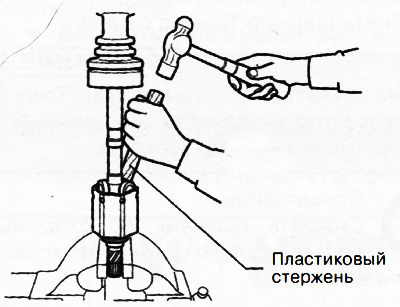

22. Aligning the alignment marks on the shaft and hinge, install the Tripod hinge on the shaft using a hammer and a suitable rod.

23. Insert a new circlip using special pliers.

24. Make sure the circlip is properly seated in the shaft groove.

25. Using a suitable mandrel, press a new bearing onto the drive shaft.

26. Using a suitable mandrel, press a new dust ring onto the drive shaft.

27. Lay in the outer ring with anther (from the gearbox side) the necessary lubricant.

Note:

Do not touch lubricant with hands. Apply grease through a grease gun to prevent foreign material from entering the boot. Amount of lubricant:

- SKYACTIV-G 2.0 petrol engine: 89-99

- Diesel engine SKYACTIV-0 2.2: 155-175 g.

28. Fix the outer ring in a vise.

Attention. Be careful when clamping the outer ring in a vise as this may deform the outer ring seal.

29. Align the rollers with the grooves in the outer ring and, lightly tapping the rollers with a hammer through a wooden or plastic rod, install the drive shaft into the outer ring, keeping the drive shaft vertical.

Attention. Ensure that foreign material does not get into the outer ring of the joint (e.g. dust or dirt), otherwise the drive shaft may be damaged.

30. Adjust the length of the drive shaft to the standard value (see section "Service Data" at the beginning of the chapter).

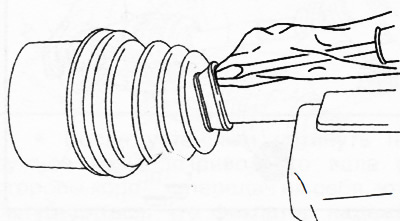

31. Release all air from the anthers by carefully prying up the small diameter edges of each anther with a flat screwdriver wrapped in cloth.

Note:

- Check that there are no grease leaks due to damaged boots.

- If the boot is damaged, it may not be possible to adjust the length of the drive shaft.

32. Verify that the length of the drive shaft is correct at atmospheric pressure inside the boot. If the shaft length is not correct, repeat the assembly of the Tripod hinge from the beginning.

33. Using pliers, pry off the large-diameter anther collar at the points indicated in the figure and tighten the collar.

34. Make sure that the clamp is securely installed on the boot.