Attention. The engine stand is equipped with a self-locking mechanism. However, if the rear final drive is tilted, the self-locking mechanism may not work. If the rear final drive turns unexpectedly, it could cause injury. Therefore, do not carry out work on an inclined rear final drive. When overturning the rear final drive, it must be securely supported by hands.

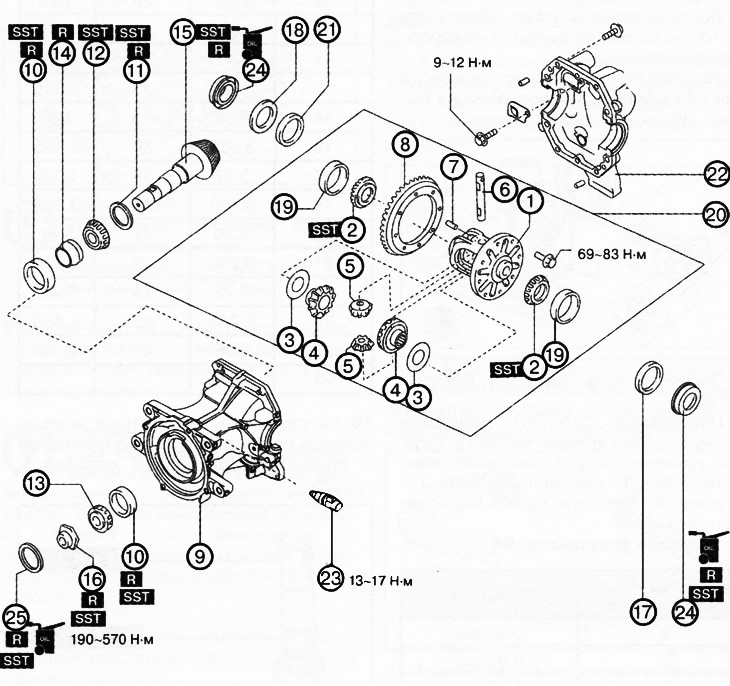

1. Differential box.

2. The inner rings of the side bearings.

3. Thrust washers.

4. Side gears.

5. Satellites.

6. Axis of satellites.

7. Pin.

8. Ring gear.

9. Rear final drive housing.

10. Bearing outer ring.

11. Spacer.

12. The inner ring of the rear bearing.

13. The inner ring of the front bearing.

14. Composite spacer.

15. Main gear drive.

16. Lock nut.

17. Left shim.

18. Spacer.

19. The outer ring of the side bearing.

20. Rear differential assembly.

21. Right shim.

22. Rear cover of the final drive housing.

23. Rear final drive oil temperature sensor.

24. Side gear seals.

25. Coupling gland.

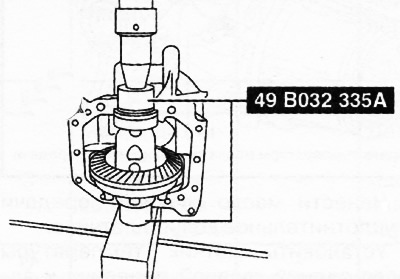

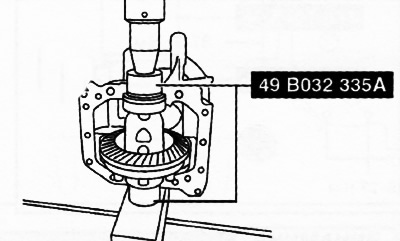

Note:

: replace the part with a new one after each removal.

: use a special tool or attachments.

: apply lubricant.

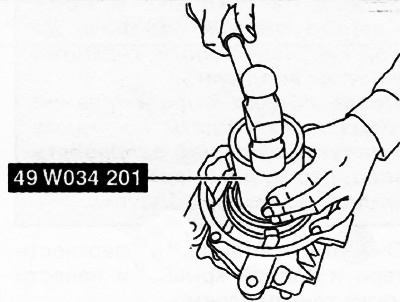

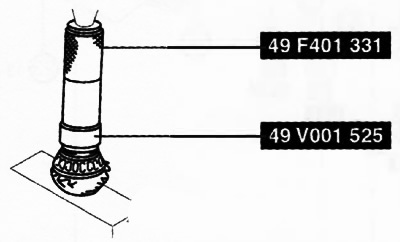

1. Using a suitable drift, press the inner races of the side bearings onto the differential case.

Attention. Do not confuse the left and right side bearings.

2. Assemble the side gears, thrust washers and pinion gears into the differential case, install the pinion axle and insert the pin.

3. After inserting the pin, crimp it so that the pin does not fall out of the differential box.

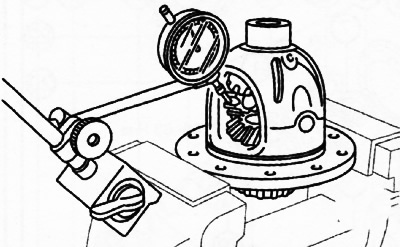

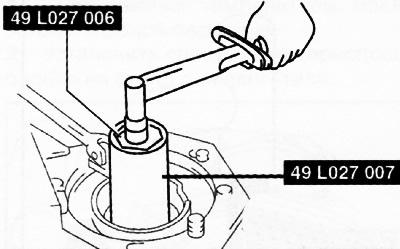

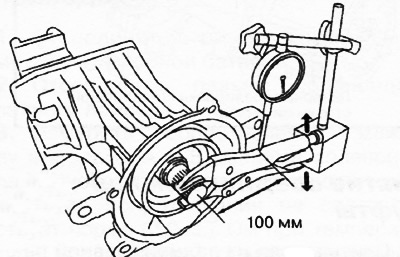

4. Install a dial indicator on the satellite as shown in the figure.

5. Fix one of the side gears.

6. While moving the satellite, measure its play with a dial indicator. If the amount of backlash exceeds the norm (no more than 0.1 mm), use an appropriately sized thrust washer for adjustment.

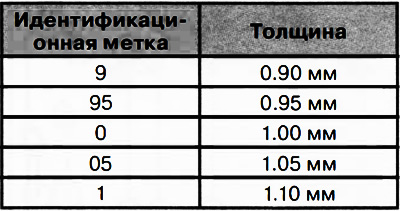

Thickness of thrust washers

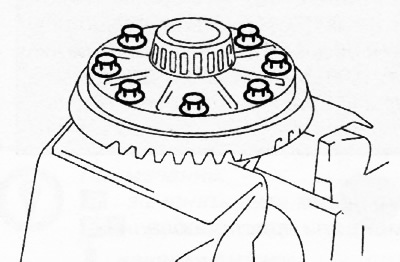

7. Align the marks made on the ring gear and the differential box during disassembly and tighten the fastening bolts in a diagonal sequence to a torque of 69-83 Nm.

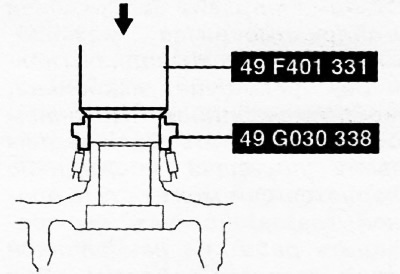

8. Using a suitable mandrel and a press, press the bearing outer races into the final drive housing.

9. Install a new spacer of the same size as the one previously installed.

10. Press the rear bearing inner race onto the pinion shaft using a suitable mandrel and press.

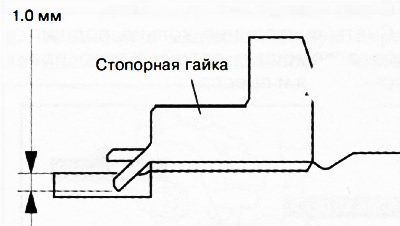

11. Apply final drive oil to the new lock nut.

12. Assemble the new compound spacer, front bearing inner race and spacer onto the pinion shaft and install the lock nut.

13. Turn the threaded part of the pinion shaft by hand to seat the bearing.

14. Tighten the lock nut to the lower limit of the specified torque range (190-570 Nm), thus creating the necessary preload. If the required preload (0.9-1.6 Nm) not ensured, replace the compound spacer and check the preload again.

15. Compress the lock nut with a chisel and hammer.

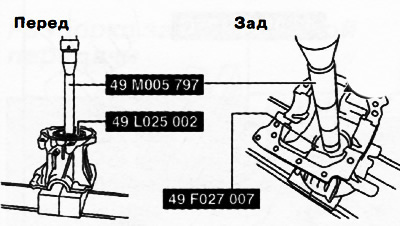

16. Install the reverse final drive housing on a special tool on the engine stand.

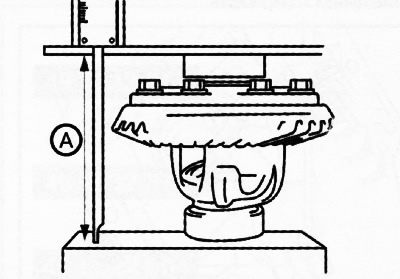

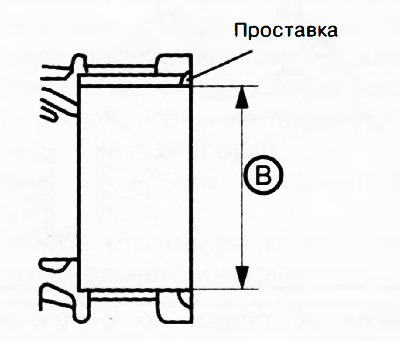

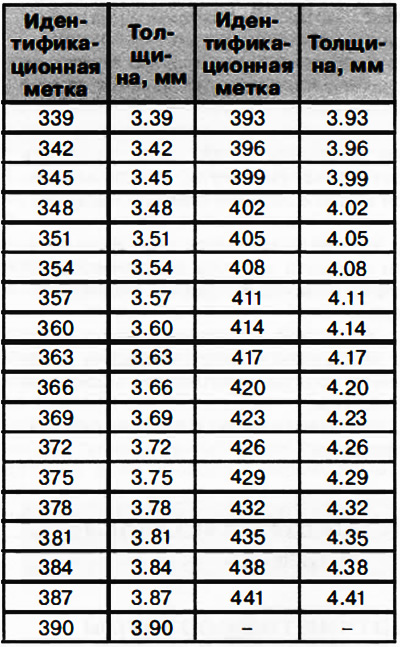

17. Install the spacer on the rear final drive housing.

18. Place the differential case with the outer races of the side bearings on a flat surface as shown in the illustration and measure the height with a caliper and straight edge. This is the value of A.

19. Measure the width of the installed differential in the final drive housing with the spacer installed. This value is V.

20. The total thickness of the left and right shims is determined by the following formula.

- C1 =B-A+0.16mm

- C2 =B-A+0.25mm

21. If the total thickness of previously installed shims is between C1 and C2, use these shims.

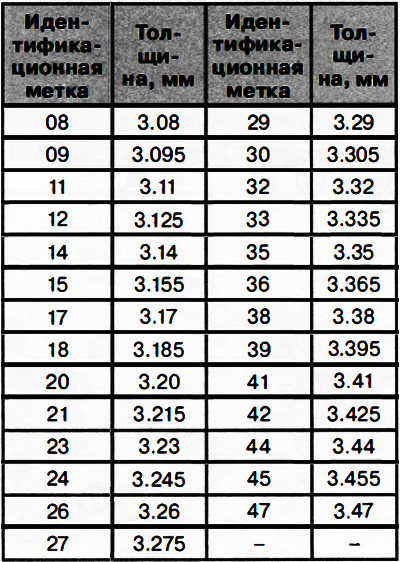

22. If the total thickness of the previously installed shims is not between C1 and C2, the shims must be replaced by selecting two suitable shims from the following table.

Thickness of shims

Attention.

- If shims are reused, do not confuse left and right shims.

- Do not confuse left and right side bearing outer races and spacers.

23. Install the differential with outer bearing races in the differential housing.

24. Drive the selected shims between the spacer and the bearing race with a plastic hammer.

25. Clean the contact surfaces of the crankcase and rear final drive cover.

26. Using a special tool (49 8032 335A), use a press to pressurize the final drive housing as shown in the illustration, and install the rear final drive cover.

Attention. Do not apply more than 2 tons of force.

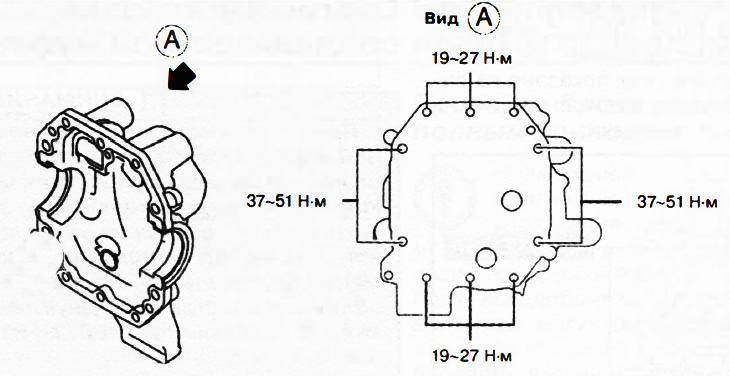

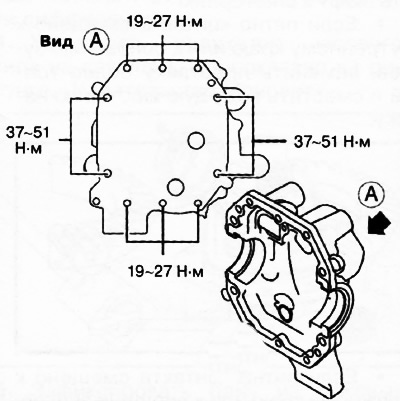

27. Fit the bolts and tighten to the tightening torques shown in the figure.

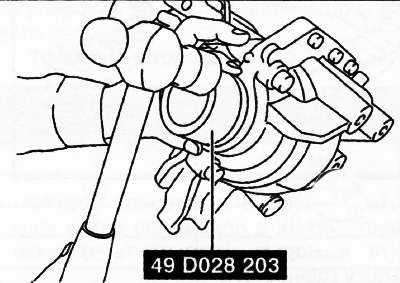

28. Place an adjustable wrench or similar tool on the gear shaft splines as shown in the figure and measure the play at a distance of 100 mm from the center of the shaft.

Note:

Backlash of the gear shaft of the rear final drive:

- Standard: 0.13-0.21mm.

- Minimum: 0.07 mm.

29. If the play is not correct, adjust the position of the differential assembly by moving it in the axial direction.

Note: When moving the differential assembly axially, replace the shims. If the right side shim is replaced with a new one 0.05mm thicker, replace the left side shim with a new one 0.05mm thinner.

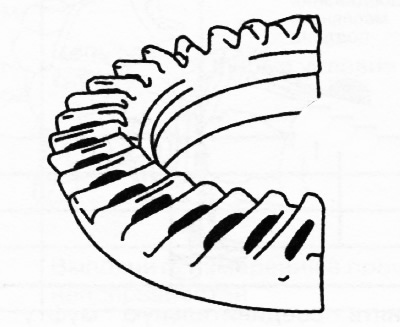

30. Check the contact patch in the teeth of the drive gear and the main gear ring gear:

- Apply a uniform thin layer of the coloring composition on both surfaces of the ring gear.

- Turn the ring gear back and forth several times by hand and check the spot in the meshing of the teeth.

- Check the contact patch in the meshing of the teeth at four points around the circumference of the ring gear to ensure that the position of the contact patch is correct everywhere. If the contact patch is normal, remove the paint from the teeth. If the contact patch is misaligned, adjust the pinion height and then adjust the backlash in the gears.

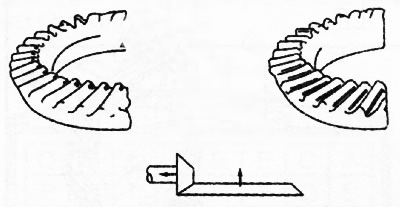

- If the contact patch is shifted to the inside edge or to the base of the teeth, replace the spacer with a thinner one and move the pinion gear outward.

|  |

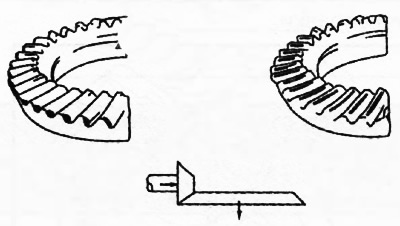

If the contact patch is shifted to the outer edge or to the top of the teeth, replace the spacer with a thicker one and move the drive gear inward.

31. If the backlash in the gears is correct, and the position of the contact patch is normal, install the rear final drive cover.

Attention.

- Before applying a new sealant, carefully remove the remnants of the old one.

- Install the rear cover on the final drive housing before the applied sealant begins to harden.

- After assembling the rear final drive, wait at least 30 minutes before adding oil to allow the sealant to cure properly.

32. Clean the contact surfaces of the crankcase and rear cover and apply a thin layer of sealant.

33. Using a special tool (49 8032 335A), use a press to pressurize the final drive case as shown in the figure, and install the rear cover on the final drive case.

Attention. Do not apply more than 2 tons of force.

34. Install the bolts and tighten to the tightening torques shown in the figure.

35. Apply final drive oil to the lips of the new side oil seal and install the oil seal using a suitable drift.

36. Apply final drive oil to the lip of the new coupling oil seal and install the oil seal using a suitable drift.