1. Rear nuts.

2. Front nuts.

3. Center bearing nuts.

4. Spacers.

5. Cardan shaft.

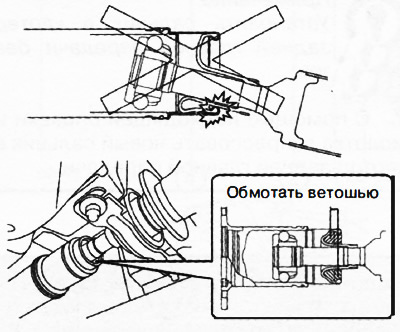

Attention. If the CV joint was bent during removal/installation or while transporting the driveshaft, the CV boot could touch metal parts and be damaged. Before starting repair work, insert a rag between the boot and the metal cover to protect the boot.

1. Remove the support cover from the bottom of the body

2. Remove the central protective tray.

3. Remove the exhaust pipe insulator.

4. Remove the tunnel cross member.

5. Remove the bracket from the bottom of the car.

6. Loosen the propshaft rear nuts.

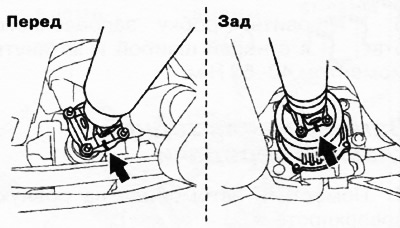

7. Before unscrewing the nuts, make alignment marks on the front connecting flange and the constant velocity joint, as well as the rear connecting sleeve and the cardan shaft yoke, as shown in the figure.

Attention. Do not punch marks to prevent imbalance.

8. Loosen nuts (front, rear and center support bearing).

9. Remove front and rear driveshaft nuts.

Attention. The cardan shaft must be mounted on threaded studs.

10. Press the cardan shaft and remove from the rear.

Attention. Do not bend the cardan shaft, so as not to damage its boot.

11. To turn away nuts of fastening of the central basic bearing and to remove cardan shaft from the car.

12. Installation is carried out in the reverse order of removal, taking into account the following:

Attention.

- If the nuts are loose, make sure that the threaded studs are screwed into the coupler with a torque of at least 6.4 Nm (if necessary, tighten the studs with a torque of 6.4-9.6 Nm).

- If, when loosening the nut, it unscrews along with the stud, replace the stud with a new one.

- When replacing the threaded studs, remove oil and other impurities from them and from the mounting surfaces.

Note: Continuous threaded studs are the same for the front and rear of the driveshaft.

Degrease tightened areas.

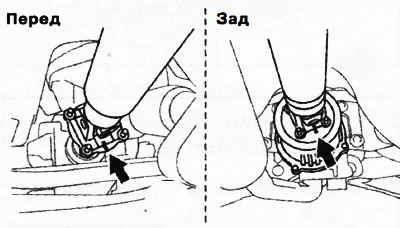

Align the alignment marks and screw on the nuts (front, rear and center support bearing).

Attention. Do not bend the cardan shaft, so as not to damage its boot.

First tighten the propshaft front nuts to the specified torque, and then tighten all other nuts.

Carry out a test drive to make sure there are no abnormal noises or vibrations.