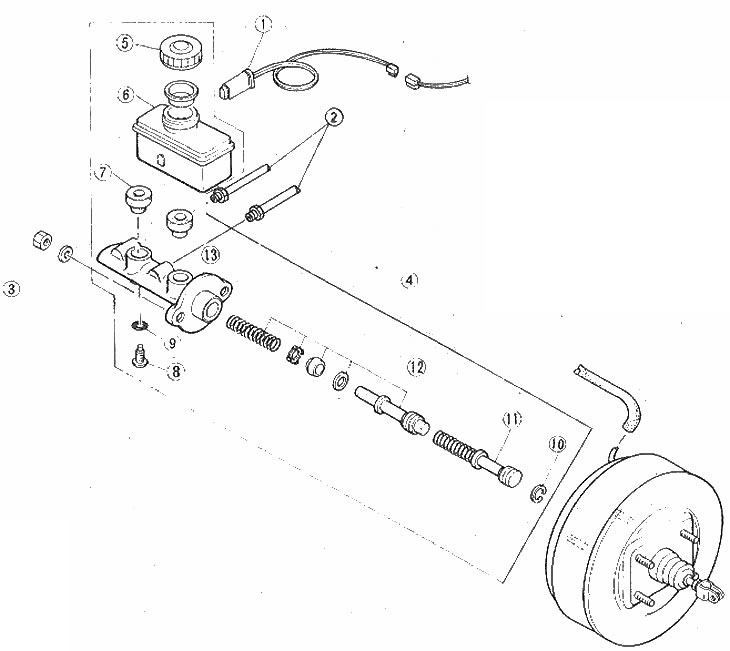

Location of master cylinder components

1. Liquid level sensor; 2. Tubes of torn system; 3. Nuts; 4. Master cylinder assembly; 5. Tank cover; 6. Reservoir; 7. Bushings; 8. Secondary piston fastening screw; 9. O-ring; 10. Thrust ring; 11. Assembly of the primary piston; 12. Assembly of the secondary piston; 13. Master cylinder body

1. Obtain a master cylinder overhaul repair kit. The kit contains all the necessary replacement parts. It is very important that the rubber seals are properly installed and tight. Be careful not to get grease or solvents on the rubber parts.

2. Cover surrounding painted surfaces where brake fluid may splash as the fluid dissolves the paint.

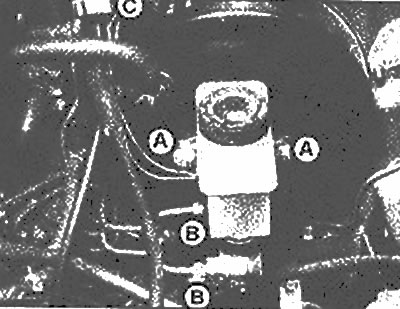

3. Disconnect the brake pipes. Place a rag or newspaper under the master cylinder to soak up the spilled liquid. Disconnect the fluid level sensor connector, remove the two master cylinder mounting nuts, and remove the master cylinder from the vehicle (photo).

Master Cylinder Lock Nuts (A), tubing connections (IN) and liquid level sensor connector (WITH)

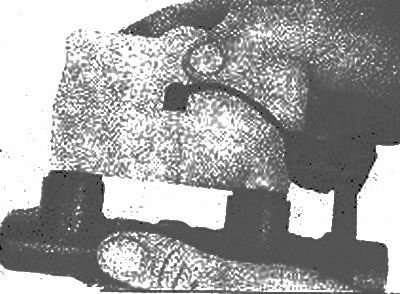

4. Drain any remaining fluid from the reservoir. Remove the reservoir by holding the master cylinder firmly and rocking the reservoir from side to side (photo).

While holding the master cylinder, rock the reservoir from side to side to remove it

5. Place the master cylinder in a vertical position (front end down), press the primary piston and remove the thrust ring.

6. Remove the primary piston and discard it.

7. Using a wooden pin, push out the secondary piston. Remove the O-ring and the mounting screw.

8. Turn the master cylinder upside down and tap it with a block of wood to remove the secondary piston.

9. Remove the spring from the forward end of the secondary piston.

10. Remove the rear spacer, cylinder head seal, valve gaskets, and two seals located on the rear of the piston from the secondary piston.

11. Remove bushings, reservoir cap and float.

12. Clean the master cylinder and inspect the cap for corrosion and damage. If such defects are found, replace the master cylinder body. The exception is when the defects are very small.

13. Inspect reservoir for cracks and bushings for wear. Replace components as needed.

14. Lubricate all components with clean brake fluid before assembly.

15. Install the valve gasket on the forward end of the secondary piston. Install the seal on the piston (open end first).

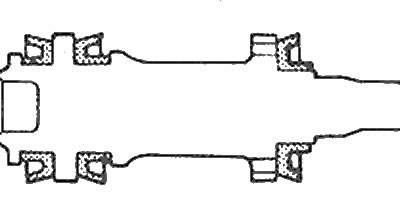

Installing secondary piston seals (shaded)

16. Install the center seal on the secondary piston (open end first).

17. Install rear secondary piston seal (open end back).

18. Place the O-ring on the secondary piston mounting screw.

19. Lubricate the primary and secondary pistons with clean brake fluid.

20. Push the secondary piston assembly into the cylinder using a wooden pin. Lightly compress the spring and insert the set screw.

21. Insert the primary piston with the spring seat forward. Slightly compress the spring and install the thrust ring.

22. Lubricate the reservoir bushings, place the reservoir on a hard surface and install the reservoir body onto the master cylinder.

23. Install the float assembly in the tank.

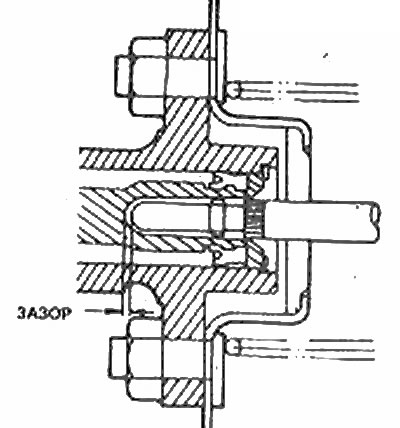

24. It is recommended to check the clearance between the primary piston and the push rod of the brake booster. Manufacturers have created a special tool for this purpose No. 49 11002 765. The gap should be 0.41-0.61 mm (booster vacuum released). The adjustment is made by turning the push rod of the brake booster, which is fastened with a lock nut.

Clearance between the master cylinder and the pusher of the vacuum brake booster

25. After installing the master cylinder, it is necessary to bleed the entire brake system. Bleeding can be completed faster if the master cylinder is filled with fluid before installation. Fill the reservoir with brake fluid and slowly push the piston all the way into the cylinder using a wooden prong screwdriver. Before releasing the piston, block the holes under the brake pipes so that air does not enter the master cylinder. Repeat the procedure until bubble-free brake fluid flows out of the cylinder. During pumping, monitor the level of liquid in the tank, do not let it empty.

26. Establish the main cylinder into place and hand-tighten the nuts of the brake pipes.

27. Install the master cylinder lock nuts and tighten them securely.

28. Tighten the brake pipe nuts securely and connect the fluid level sensor connector.

29. Bleed all the brakes (see chapter 15).