1. Remove the caliper (Chapter 3) and brake pads (Chapter 2). The caliper piston can be removed in two ways. Item 4 below describes removing the piston from the caliper removed from the vehicle. With the brake hose still attached to the caliper and the pads removed, the piston can be pushed out using hydraulic pressure. Close the caliper with a die or a cloth folded in several layers. Do not put your fingers under the piston. Have an assistant depress the brake pedal very slowly to push the piston out. Be prepared for brake fluid to come out (photo).

When extracting pistons with hydraulic pressure, use a ram to protect the caliper. Don't expose your fingers to the impact of the piston

2. Clean the outer surface of the caliper with brake fluid, denatured alcohol or special cleaner (never use gasoline or kerosene). Place the caliper on a clean workbench.

3. Remove the caliper bleeder.

4. If the piston has not yet been removed, cover the caliper with a die or rag and push the piston out of the caliper using compressed air. It is enough just to remove the edge of the piston from the hole. If the piston flies out, even if it hits a rag, it may be damaged.

Warning: Do not try to catch the piston with your fingers, as this may result in injury.

5. Remove the retainer and dust seal from the caliper channel.

6. Using a suitable wooden or plastic tool, drive the piston seal out of the groove in the caliper bore. Metal instruments can damage the canal walls.

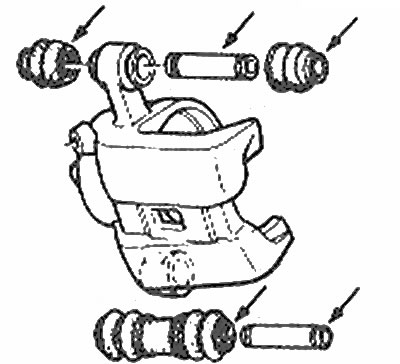

7. Remove dust covers, pins and bushings from the caliper eyes.

Case, bushing and caliper pins (arrows indicate areas requiring lubrication)

8. Clean remaining parts with brake fluid. Allow the liquid to drain, then vigorously shake off any remaining liquid.

9. Carefully inspect the piston and caliper bore for scratches, burrs, corrosion. If these defects are found, replace the parts. If the defects are minor, the caliper channel can be sanded with a fine abrasive paper. Inspect mounting bolts, pins and bushings for corrosion and damage. If necessary, replace components.

10. When assembling, lubricate the caliper channel and seal with clean brake fluid. Coat the piston seal with the red grease supplied with the seal kit.

11. Insert the seal into the groove of the caliper channel (photo).

11 Insert the piston seal into the groove of the caliper bore

12. Install the dust seal on the piston. Apply some orange grease to the dust seal (supplied with seal kit), then install the piston and dust seal into the caliper bore. Install the dust seal retainer.

13. Install the bleed valve.

14. Lubricate dust covers, bushings and dies with orange grease and install caliper.

15. Apply a small amount of grease to the brake pads. For disc brakes (Mazda 8175 49 248) or a special sound-absorbing composition. Avoid getting grease on friction surfaces. Install the brake pads.

16. Install the caliper and bleed the brakes (Chapter 15).