2. Remove the wheel.

3. Remove the caliper assembly (see chapter 3).

Note: It is not necessary to disconnect the brake hose. After removing the caliper mounting bolts, attach the caliper to the body with a piece of string. Do not let the caliper hang on the brake hose as this may damage the hose.

4. Examine the surface of the brake disc. Minor scratches or gouges are perfectly acceptable, but if there are deep gouges or severe erosion, the blade needs to be replaced or reground. Vibration felt when braking can be caused by worn brake discs or worn wheel bearings.

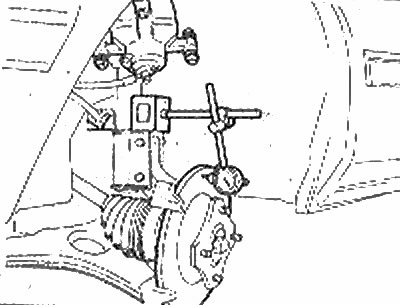

5. Install a micrometer on the caliper mounting bracket, rotate the brake disc and measure its runout. Check runout on both inner and outer surfaces. If the runout exceeds the maximum value specified in the Specifications, and the wheel bearings are known to be in good condition, remove the brake disc from the vehicle and have the dealer regrind it.

Measure brake disc runout

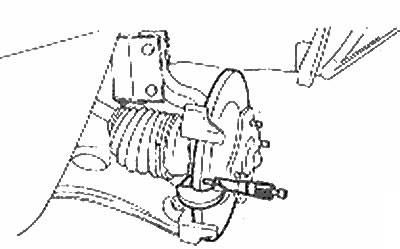

6. Using a micrometer, measure the thickness of the brake disc. If it is less than specified in Specifications at the very least, replace the drive. Measure the disc thickness at several points. If the difference between these measurements exceeds 0.0127 mm, vibration will be felt when braking. In this case, if the disc thickness permits, the disc can be reground.

Measure the brake disc thickness

7. Special tools are required to remove the disc from the hub. Remove the disk assembly with the hub (Section 10) and contact your dealer to have the disc resharpened or replaced.