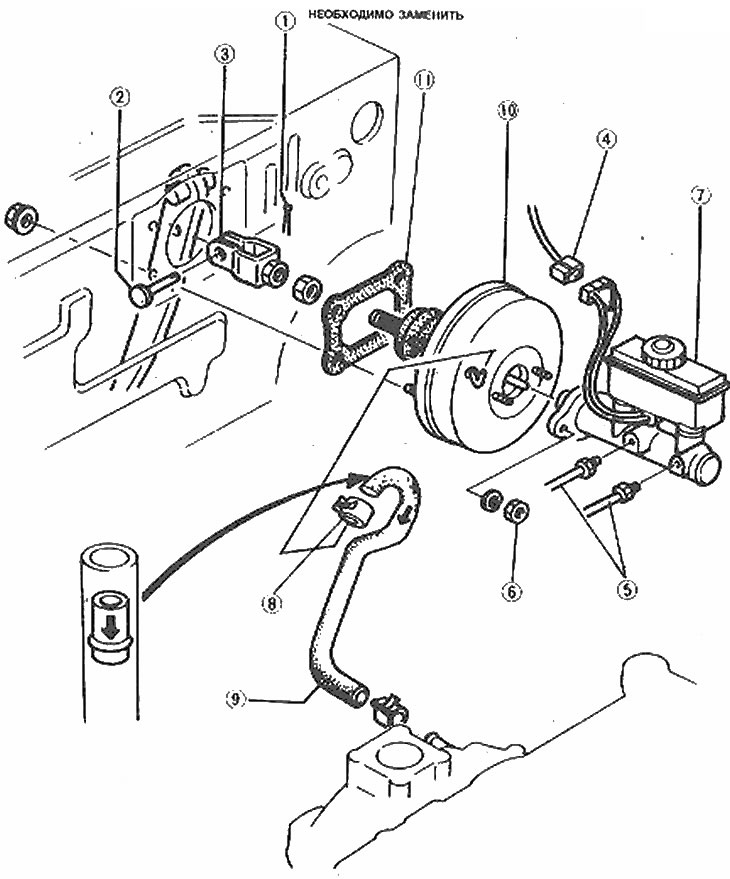

Brake Booster Components

1. Hairpin; 2. Pin with a hole for a hairpin; 3. Fork and bunny; 4. Liquid level sensor connector; 5. Brake pipes; 7. Master cylinder assembly; 8. Hose clamps; 9. Vacuum hose; 10. Vacuum brake booster block; 11. Gasket

1. The brake booster does not require any special maintenance, except for periodic inspection of the hoses and inspection of the air filter under the boot at the end of the pedal pusher.

2. Bulkhead brake booster requires the use of special tools. If the amplifier is defective, it is recommended that it be replaced rather than attempted to be repaired.

3. Remove the mounting nuts securing the brake master cylinder to the brake booster. Disconnect the brake fluid level sensor connector and move the master cylinder to the side, being careful not to deform the tubes going to the master cylinder. If there is any doubt about the flexibility of the lines, disconnect them from the cylinder and seal their ends.

4. Disconnect the vacuum hose going to the front end of the brake booster. Plug the end of the hose.

5. Remove the fan duct and trim from under the dashboard. Remove the stud and pin and disconnect the booster pushrod from the brake pedal. When disconnecting, do not move the pusher to the side.

6. Remove the four mounting nuts of the vacuum booster unit and carefully remove the unit from the engine compartment.

7. When installing a new booster, measure the gap between the primary piston of the master cylinder and the pushrod of the booster block - see Chapter 8, paragraph 24.

8. Fit four mounting nuts and connect the pusher to the brake pedal. Tighten the nuts and connect the vacuum hose to the master cylinder. If the brake pipes have been disconnected, bleed the entire system (see chapter 15).

9. Check the position of the free play of the brake pedal and adjust them if necessary - see Chapter 11, point 8.