General description

1. The air intake system helps reduce hydrocarbons and carbon monoxide in the exhaust by introducing air into the intake ports of each cylinder.

2. The air intake system uses exhaust pressure pulses to pull air into the exhaust system and uses fresh filtered air.

3. Parts used in the system include thin valves located in the air filter, external fittings and hoses.

Examination

4. Exhaust gas flowing back through the air filter assembly is a sign of damage to the air intake system. When starting any inspection, carefully check all hoses. Make sure they are in good condition, all connections are tight and clean.

5. A simple, functional test of this system can be performed with the engine running.

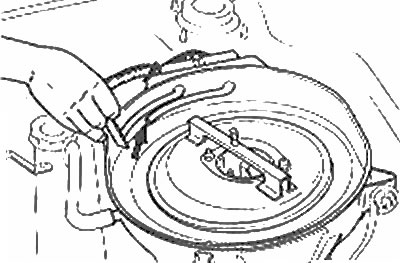

6. Remove the top of the air filter and filter element assembly.

7. With the engine at normal idling temperature, place a piece of paper over the burner valve inlet port. With the engine idling, there should be a steady flow of air drawn into the valve. Get a helper to control the throttle and once the engine changes speed, see if the suction increases.

Checking the operation of the thin valve of the air intake system with a piece of paper |

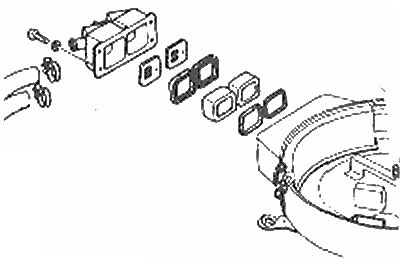

Fine Valve Details |

8. If this does not happen, the hoses are leaking or clogged, or the thin valves are faulty.

9. Increase engine speed to approximately 1500 rpm and check for exhaust gas leaks at the vent connection.

10. Replace the thin valve with a new one if it fails any of the tests.

Replacement Parts

11. Remove the air filter.

12. Remove the screws securing the thin valve housing cover and remove the valves and filters from the housing (photo).

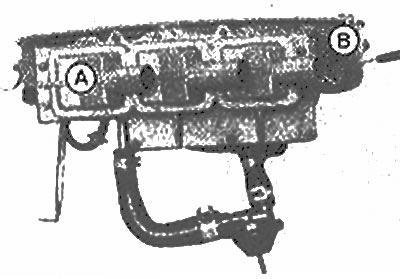

Slim valve assembly (A) attached to the air filter housing (IN) screws |

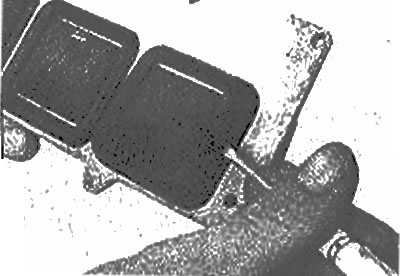

Use a small screwdriver to pry out the thin valve |

Removing the thin valve from the casing

13. Assembly is carried out in the reverse order.