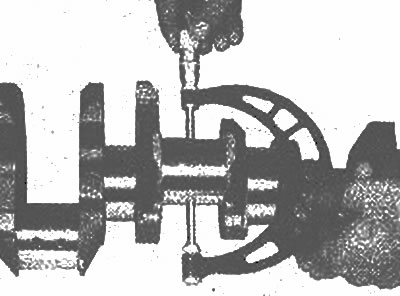

2. Using a micrometer, measure the diameter of the crankshaft main and connecting rod journals and compare the results with the specifications. The diameter should be measured at several points on the neck to determine if it has become oval. Take a measurement at each end of the neck near the counterweights to determine if it is tapered (photo). If you do not have a micrometer, contact a service station.

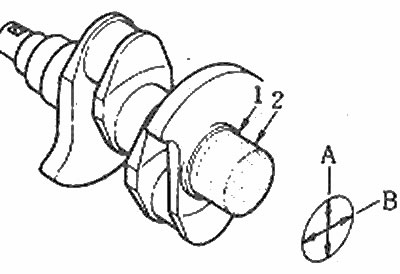

Measure the crankshaft at two points (1 and 2) and four directions (A and B) on each neck |

Measure the diameter of each crankshaft journal at several points to find taper |

3. If the crankshaft journals are damaged, tapered, oval or worn beyond the limits given in the Specifications, the crankshaft must be reground - contact a specialist. Remember that after regrinding the crankshaft, bearing shells of the correct size must be used to obtain proper running clearance.

4. Guided Chapter 18, inspect the main and connecting rod bearing shells for unusual wear.