2. Position the piston/rod assemblies and new rings in the same cylinders.

3. Insert the top ring (№1) into the first cylinder by pushing it with the top of the piston (photo). The ring should be near the base of the cylinder. Measure clearance. inserting a feeler gauge between the ends of the ring (photo). Compare measurement with specifications.

Before checking the piston ring clearance, the ring should be perpendicular to the cylinder liner. This can be achieved by pushing the rings into the cylinder |

With the ring perpendicular to the cylinder, measure the clearance with a feeler gauge |

4. If the clearance is greater or less than specified in Specifications, then first make sure that you have chosen the rings of the desired repair size.

5. If the gap is too small, then it must be increased. The gap is bored with a small file clamped in a vise. Place the file in a vise equipped with soft jaws and grind the rings slowly (photo).

To increase the gap of the ring, fix the needle file in a vise and carefully grind the ring

6. It is allowed to grind no more than 1 mm. If there is a need to grind more, then most likely you are dealing with rings of the wrong repair size.

7. Repeat the procedure for each ring in the first cylinder and for each ring in the remaining cylinders.

8. Once the gaps are correctly set, the rings can be installed on the pistons.

9. Oil scraper ring (the bottom of the piston) installed first. It is made up of three separate components. Install gasket/expander in groove (photo), then install the lower part. Do not use a tool to install the oil scraper ring, as it can be easily damaged. Instead, place one end of the ring in the groove between the gasket/expander and push the other end (photo). Then, install the top part in the same way.

Install the oil ring expander in the lower groove of the piston and check that its ends fit correctly into the lock |

When installing the oil scraper ring, use a ring installation tool |

Installing the oil scraper ring and the location of the gaps

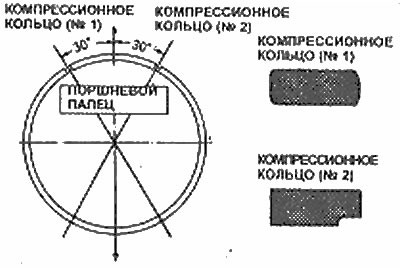

10. After the three components of the oil slinger are installed, check that both the top and bottom parts rotate easily in the groove. See accompanying ring installation illustration.

11. Ring number 2 (average) set next. It is stamped with the R mark, which must face the top of the piston.

Note: Follow the instructions printed on the ring manufacturer's box. Do not interchange the top and middle rings as they have different cross sections.

12. Using a piston ring installer, make sure the ring markings are facing the top of the piston. install the ring in the middle groove on the piston (photo). Do not expand the ring more than necessary. Instead of a tool for installing rings, you can use a feeler gauge - see chapter 16.

Use a ring expander to install a compression ring

13. Install ring #1 in the same way (top). Check that the ID mark is in the correct position. Be careful not to mix up the ring numbers (#1 and #2). See related illustration.