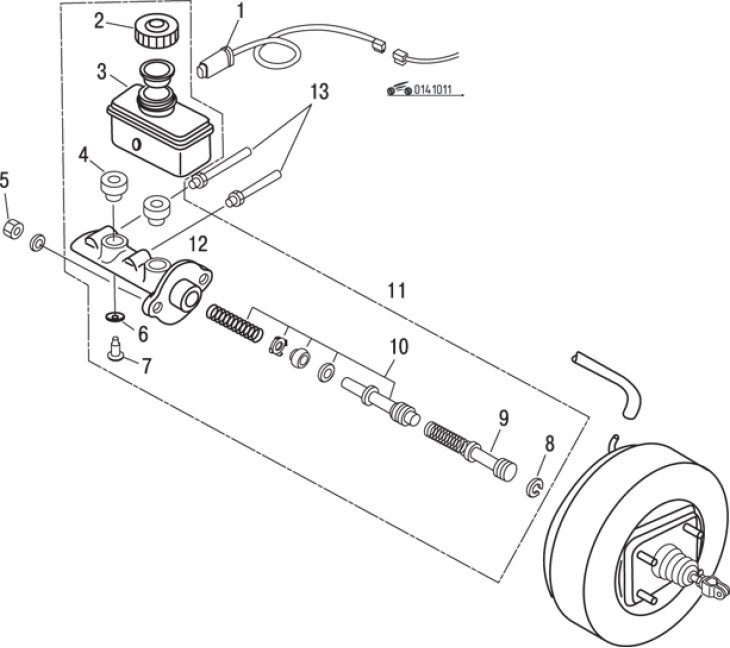

Pic. 10.11. Master brake cylinder: 1 - brake fluid level sensor; 2 - tank cover; 3 - reservoir for brake fluid; 4 - bushing; 5 - nut; 6 - ring seal; 7 - locking screw; 8 - thrust ring; 9 - assembly of the primary piston; 10 - assembly of the secondary piston; 11 – assembly of the main brake cylinder; 12 - the main brake cylinder; 13 - brake pipes

Removing

Disconnect the brake pipes from the master brake cylinder. To collect leaking fluid, place rags or newspapers under the brake master cylinder. Disconnect the connector from the brake fluid level sensor, unscrew the two nuts securing the brake master cylinder and remove the brake master cylinder from the vehicle (fig.10.11).

Drain the remaining brake fluid from the reservoir. Remove the reservoir by holding the master cylinder firmly and rocking the reservoir from side to side.

Install the master cylinder in a vertical position (the front should be pointing down), press the primary piston and remove the thrust ring.

Remove the primary piston. The repair kit includes a replacement part.

Press the secondary piston with a wooden rod, remove the O-ring and remove the screw.

Tap the master cylinder against a piece of wood to remove the secondary piston.

Remove the spring from the front of the secondary piston.

Remove the rear spacer and cylinder cup seal, valve gaskets, and two seals from the rear of the piston from the secondary piston.

Remove the tank bushings, cover and float.

Clean the master cylinder and inspect the bore for signs of corrosion or damage. If significant corrosion or damage is found, replace the brake master cylinder housing.

Inspect the tank for cracks and the bushings for wear, replacing them with new ones if necessary.

Lubricate all components with clean brake fluid before assembly.

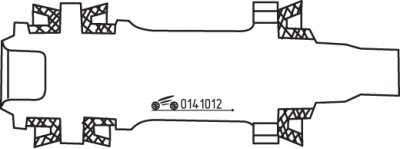

Pic. 10.12. The location of the seals on the secondary piston of the master cylinder

Install the valve gasket in front of the secondary piston. Place the seal on the piston (open part forward) (pic. 10.12).

Install the center seal on the secondary piston, open side first.

Install the rear secondary piston seal with the open side toward the rear.

Install the O-ring on the secondary piston mounting screw.

Repair

Purchase a brake master cylinder repair kit.

Unscrew the bleed screw and shake out the steel ball. If necessary, to remove the ball, tap the working brake cylinder on a wooden block.

Attention! Avoid getting brake fluid on the car's paintwork, as it can destroy it.

Remove the dust covers and pistons from the cylinder bore, then separate the covers from the pistons.

Press the piston on one side of the bore to remove it and to remove the spring cup and spring.

Clean the working brake cylinder with brake fluid, denatured alcohol or using a brake cleaner. Under no circumstances should oil-based solvents be used to clean brake parts.

Use compressed air to remove excess fluid from the working brake cylinder and blow out the passages.

Check the brake cylinder bore for signs of corrosion and scoring. To remove them, it is allowed to machine the hole with fine-grained abrasive paper, but it is necessary to replace the cylinder with a new one if it is impossible to eliminate defects or the hole has burrs.

Lubricate the new cups and the brake cylinder bore with clean brake fluid.

Install the spring, spring cups and piston cups into the cylinder.

Make sure the cups are properly installed (the open ends of the cup should point inwards).

Install new piston covers. Lubricate the pistons with clean brake fluid. If the repair kit includes a brake lubricant kit, apply lubricant to the inside of the boot (or according to instructions).

Install the pistons and boots into the brake cylinder, making sure the boots are positioned correctly.

Install the steel ball and screw in the bleed screw.

Installation

Correctly position the working brake cylinder, tighten the union nut of the brake tube by hand and check that there are no distortions.

Screw in the brake cylinder mounting bolts and tighten them securely.

Tighten the brake tube union nut and install the brake shoe assembly.

Install the brake drum and adjust the wheel bearings. Install the wheel and secure it with nuts.

Bleed the hydraulic brake system and lower the vehicle.

Lubricate the primary and secondary pistons with clean brake fluid.

Use a block of wood to push the secondary piston into the master cylinder bore. Slightly compress the spring and screw in the screw.

Insert the primary piston with the spring forward. Slightly compress the spring, then install the thrust ring.

Lubricate the reservoir bushings, place the reservoir on a hard surface and, rocking it, press the master cylinder body onto the reservoir.

Install the float switch for the brake fluid level.

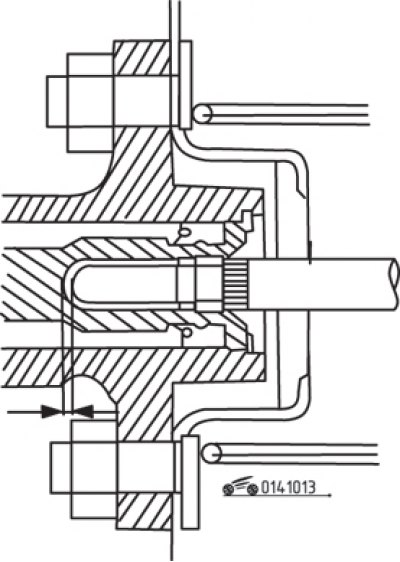

Pic. 10.13. Clearance between the primary piston and the pusher of the vacuum brake booster

Theoretically, it is necessary to measure the gap between the primary piston and the pusher of the vacuum brake booster (pic. 10.13). The manufacturer produces a special tool 49 B002 765 for this purpose. If it is not available, use a depth gauge or similar tool to determine the depth of the recess in the primary piston and the protrusion of the vacuum booster pusher. The recommended value without applying vacuum to the amplifier is 4.06-6.09 mm.

Adjustment is made by rotating the vacuum booster pusher held by the locknut.

Each time the brake master cylinder is removed, the hydraulic system must be completely bled. The time to prime the system can be reduced if the master cylinder is filled with fluid and pumped or «tested in a test way» prior to installation on the vehicle. Fill the reservoir with brake fluid and slowly push the piston all the way in using a wooden rod or Phillips screwdriver. Before releasing the piston, block the brake line connections to prevent air from entering the brake master cylinder, then release the piston. Repeat the procedure until brake fluid without air bubbles comes out of the brake line connections. Be careful - do not allow the bottom of the tank to be exposed during pumping.

Correctly position the main brake cylinder on the studs of the vacuum brake booster and with your fingers, without distortions, tighten the cap nuts of the brake pipes.

Tighten the brake master cylinder nuts securely.

Securely tighten the union nuts of the brake pipes and connect the connector to the sensors.