Clean the outside of the caliper with brake fluid, denatured alcohol or a brake cleaner (never use gasoline or kerosene), then place the caliper on a clean workbench.

Turn out the union for removal of air.

If the piston has not been removed, remove it from the caliper by supplying low-pressure air to the brake cylinder through the brake hose connection hole, replacing the brake shoes with a wooden block. Use just enough air pressure to push the piston out of the hole. If the piston is thrown out with great force, even if the block of wood remains in place, the piston may be damaged.

Attention! When using compressed air to extract a piston, never put your fingers in front of the piston in an attempt to catch or protect it, as serious injury may result.

Remove the retainer and dust seal from the caliper piston bore.

Using a wooden or plastic tool, pry the piston seal out of the groove in the caliper cylinder. Using metal tools can damage the caliper cylinder.

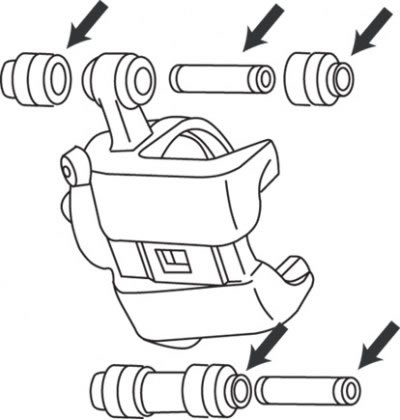

Remove the dust covers, guide pins and bushings from the caliper ears.

Clean remaining parts with brake fluid. Wait until all the brake fluid has drained and then shake the parts vigorously to remove as much fluid as possible.

Carefully examine the piston and caliper cylinder for notches, scuffs, corrosion and scuff marks. If surface defects are found, replace parts. It is allowed to process the caliper cylinder with fine-grained sandpaper to remove traces of light corrosion and stains. Inspect bolts, pins and bushings for signs of corrosion and damage, replace worn parts as necessary.

Lubricate the piston bore and seal with clean brake fluid when assembling. Apply the red grease from the repair kit to the piston seal.

Install the seal in the groove of the caliper cylinder.

Put the dust seal on the piston. Apply some of the orange grease from the repair kit to the dust seal, then install the piston and dust seal into the caliper cylinder. Install the dust seal retainer.

Screw the bleed valve into the caliper.

Pic. 10.4. Lubrication points for boots, guide pins and caliper pins

Lubricate dust covers, guide pins and pins with orange grease and install in caliper (pic. 10.4).

Apply a light coat of lubricant to the brake pad gaskets (part number 817 549 248 according to Mazda specification) or a special soundproofing composition. Keep lubricant away from friction surfaces. Install the brake pads.

Install the caliper and bleed the hydraulic brake system.