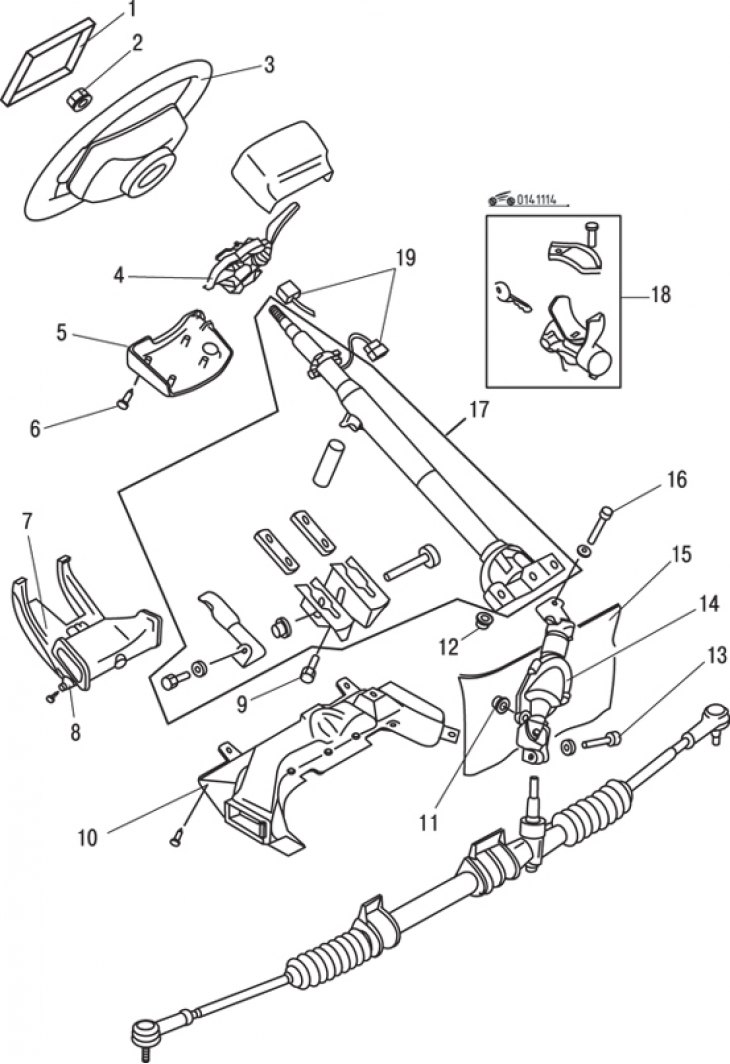

Pic. 11.14. Steering: 1 – sound signal button; 2, 11, 12 - nuts; 3 – a steering wheel; 4 – combination switch; 5 – a casing of a steering column; 6 - screw; 7 - bottom panel; 8 - screws; 9, 13, 16 - bolts; 10 - air duct; 14 - intermediate shaft; 15 - partition of the engine compartment; 17 - steering shaft; 18 – steering column lock; 19 - pin connectors

All models are equipped with rack and pinion steering, including steering wheel, steering column, intermediate shaft, steering gear, tie rods and steering knuckles (pic. 11.14).

The power steering also includes a belt-driven pump to generate hydraulic pressure. In non-power steering, the movement from the steering wheel is transmitted through the steering column and intermediate shaft to the steering gear shaft. The teeth on the pinion shaft are connected to the rack teeth so that when the shaft is turned, the rack moves to the left or right in the steering gear housing. Attached to each end of the rack are tie rods, which in turn are attached to the steering knuckles on the front wheels. Thus, the force of the rack moving to the right and to the left is directly the force that turns the wheels.

To reduce the force applied to the steering wheel to turn it, hydraulic power steering is installed on cars. As an additional force, a high-pressure working fluid is used, which is supplied to the working cylinders located on the steering gear. The distribution valve is used to pump fluid into the power cylinder under pressure, which corresponds to the angle of rotation of the steering wheel. Diverter valves operate according to the so-called open center principle, i.e. when the control valve is inactive, the liquid supplied by the pump is bypassed back into the reservoir at zero pressure. The hydraulic system is pressurized by a pump driven by a belt from the engine crankshaft pulley.

The energy-absorbing steering column folds down in the event of a frontal collision to reduce the chance of injury to the driver. The steering column also includes an ignition switch with steering lock, a warning buzzer, and switches for the turn signal, headlights, and windshield wipers. Due to the design features (developing) steering column, it is important that only special screws, bolts and nuts are used, which must be tightened to the required torques.

In addition to the standard steering column, it is possible to install a column with an adjustable tilt angle.

Technical specifications

- Type - Rack and pinion steering

- Turning radius, m - 5.1

Tightening torques, Nm

| Nut of fastening of a tip of steering draught | 30–45 |

| Nut of fastening of an intermediate shaft | 18–27 |

| Steering gear to body | 32–47 |

| Steering wheel nut | 40–50 |

| Nuts/bolts of fastening of a bracket of a steering column | 16–23 |

| wheel nuts | 90–120 |