Tightening torques, Nm

- Rear brake caliper guide pins - 63–82

- Rear brake caliper mounting brackets - 49–74

Accessory Drive Belt Tension Adjustment

Some later models do not have a belt tension adjuster, because the adjustment is made by moving the alternator or A/C compressor.

Adjusting the engine idling speed and the quality of the air-fuel mixture (engines with PBT system)

Apply the parking brake and place the shift lever in neutral.

Connect a tachometer to the engine and turn off all electrical consumers.

Start the engine and warm it up to normal operating temperature, then let it run at a crankshaft speed of 2500-3000 min-1 for 3 minutes.

Stop the engine and install the exhaust gas analyzer sensor in the exhaust pipe.

Start the engine and leave it to idle. If the electric radiator fan turns on, wait until it turns off.

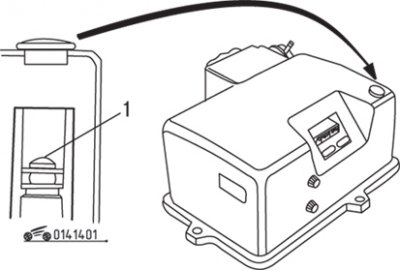

Pic. 14.1. Screw location (1) adjusting the air supply when the engine is idling

Check engine idling speed and compare with specification. If the frequency differs from the required one, adjust it by turning the air supply screw (pic. 14.1).

To adjust the composition of the air-fuel mixture, disconnect the pipes of the air intake system from the air filter and close them with suitable plugs.

Start the engine and warm it up to normal operating temperature, let it run at a crankshaft speed of 2500-3000 min-1 for 3 minutes and leave it to idle. If the electric radiator fan turns on, wait until it turns off.

Check the CO content in the exhaust gases and compare the result with the technical data. If the CO content is not correct, remove the rubber plug from the air filter and adjust the CO content by turning the air supply adjusting screw with the Mazda §49 HC27 140 special tool., so it is impossible to make such a tool on your own.

Replace the rubber plug, then adjust the idle speed.

Checking and adjusting the ignition timing (engines with PBT system)

This operation is in principle similar to the operation given in subsection «Checking and adjusting the ignition timing» (see sect. 2 «Adjustments and maintenance»), but before checking and adjusting the ignition timing, additionally disconnect and plug the tube of the vacuum regulator of the ignition distributor. Upon completion of the check, replace the tube and check that the ignition delay vacuum valve is set correctly.

Checking the rear disc brakes

Block the front wheels, raise the rear of the vehicle and secure it on stands. Remove rear wheels.

Through the hole in the back of the caliper, check the thickness of the brake pads, which must be at least 1.0 mm, otherwise replace all four rear brake pads.

Check the brake hoses for cracks and cuts, check the calipers for leaks and signs of damage.

Check the rear brake discs for deep scratches and if there are any, replace them.

Install the rear wheels and lower the vehicle to the ground.

Checking and adjusting the carburetor damper (engines with PBT system)

Fully open the throttle, then press the carburetor damper rod with your finger and check that it moves slowly. After releasing the thrust, it should quickly return to its original position.

To adjust the carburetor damper, start the engine and warm it up to normal operating temperature.

Stop the engine and connect the tachometer.

Increase the engine speed to 3500 min-1, then slowly reduce the speed and check that the throttle lever touches the damper rod at a speed of 3000+100 min-1.

If necessary, loosen the locknut and set the rod to the required position.

After adjustment, tighten the locknut and remove the tachometer.

Fuel filter replacement (engines with PBT system)

The fuel filter is located on the left side of the engine compartment.

Place a piece of cloth under the fuel filter to collect leaking fuel.

Turn out hollow bolts and disconnect hoses from the fuel filter. Remove washers.

Loosen the nuts and remove the fuel filter. Loosen the clamp bolt and remove the bracket.

Check the filter mounting rubber for wear and replace if necessary.

Install a new fuel filter. Installation is carried out in the reverse order of removal.

Air filter replacement (engines with PBT system)

Remove the four bolts securing the air filter cover and air flow meter to the bottom of the housing.

Remove the cover and take out the air filter.

Wipe the inside of the lid and bottom of the case. If necessary, you can completely remove the lower housing by unscrewing the nuts and disconnecting the air supply hose.

Install a new air filter. Installation is carried out in the reverse order of removal.

Replacing wiper blades

The wiper blades and arms of models manufactured since October 1984 have been modified. The brush is attached to the arm with a hook and hinge rather than a pin and socket.

To remove the brush, first turn it at a right angle to the wiper arm, then disconnect from the hook and remove from the end of the arm. Installation is carried out in the reverse order of removal.