Checking the throttle assembly

Turn the throttle lever and make sure it moves easily. When released, the lever should touch the throttle stop screw. If necessary, clean the axle elements, check the damper for binding.

Start the engine and warm it up to normal operating temperature.

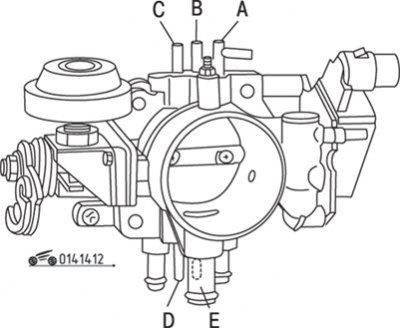

Pic. 14.12. Channel layout (A, B, C, D, E) body of the throttle assembly of the RVT system

Set the idle speed, then disconnect the hoses in turn and check the pressure in the channels, guided by fig. 14.12. On the channels «A», «IN» And «WITH» there should be no vacuum, on the channels «D» And «E» the vacuum level should be the same as in the intake manifold.

Repeat the check with engine speed higher than idle. in channels «A», «IN» And «WITH» there must be a vacuum in the channels «D» And «E» vacuum should be less than in the intake manifold.

Removal and installation of the throttle assembly

Drain the coolant.

Loosen the clamp and disconnect the air inlet hose.

Disconnect the accelerator cable and connector from the throttle position sensor.

Turn out bolts of fastening of an arm.

Disconnect the vacuum hoses from the top pipes.

Disconnect the cooling hoses and air hose from the bypass valve.

Turn out bolts of fastening of a throttle knot to an expansion chamber, remove a lining and disconnect the remained vacuum hoses.

Installation is carried out in the reverse order of removal. Install a new gasket and fill with coolant. Adjust the location of the throttle position sensor and the engine idle speed.

Checking and adjusting the throttle position sensor

Remove the rubber boot from the sensor connector located on the throttle body.

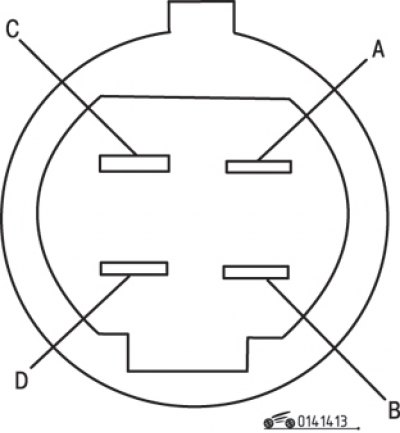

Pic. 14.13. The location of the contacts of the connector of the throttle position sensor of the PBT system

Turn on the ignition and use a voltmeter to measure the voltage between each of the connector pins and «weight» (pic. 14.13). On contact «A» there should be a voltage of 0.4–0.6 V, on the contact «IN» - less than 1.5 V, on the contact «WITH» – 4.5–5.5 V and on the contact «D» - less than 1.5 V.

Fully open the throttle and retest. On contact «A» there should be a voltage of 4.5 V, on the contact «D» - approximately 12 V. On the contacts «IN» And «WITH» should be the same voltage as measured earlier.

If the contact voltage «D» does not correspond to the required value, check the adjustment of the throttle position sensor. If the voltage on the other pins does not match the required values, check the resistance of the throttle position sensor.

Switch off the ignition and install the rubber casing.

To adjust the throttle position sensor, disconnect the connector.

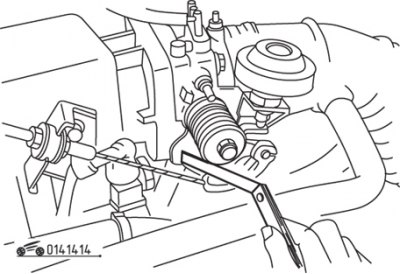

Pic. 14.14. Using a feeler gauge to adjust the PBT throttle position sensor

Insert a 0.2 mm gap tester between the throttle lever and the adjusting screw, then measure the continuity between the contacts with an ohmmeter «D» And «IN» on the sensor (pic. 14.14). Insert a probe 0.5 mm thick, the resistance between the contacts should be equal to infinity.

If necessary, adjust the position of the probe to obtain the desired results.

Before connecting the connector with an ohmmeter, measure the resistance between the connector pins. When the throttle is closed, the resistance between the contacts «A» And «IN» should be about 500 ohms, and with the damper open - about 4500 ohms. Between contacts «IN» And «WITH» resistance should be between 4000-6000 ohms regardless of throttle position, otherwise replace the sensor.