A diaphragm type damper at the fuel pump outlet reduces the fuel pressure pulses generated by the pump rollers. The fuel pump has a valve designed to maintain residual pressure in the system when the engine is not running.

The fuel pump circuit contains a switch mounted on the air flow meter that turns the pump off when the engine is stopped.

Check, removal and installation

To check the pressure generated by the fuel pump, a pressure gauge and tube are needed.

Disconnect the wire from the negative battery terminal.

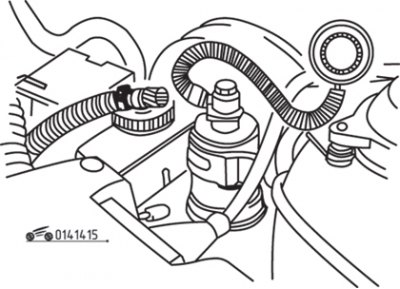

Pic. 14.15. Checking the pressure generated by the fuel pump

Disconnect the fuel hose from the fuel filter on the engine side and connect a pressure gauge instead (pic. 14.15).

Connect the wire to the negative terminal of the battery and turn on the ignition.

Pic. 14.16. Using a piece of wire to connect the contacts of the fuel pump control connector

Connect a piece of wire between the contacts of the control connector of the fuel pump (pic. 14.16) and check the fuel pressure, which should be between 3.5–5.0 kg/cm2.

To check the winding of the fuel pump armature, block the front wheels, raise the rear of the car and secure it on supports.

Disconnect the connector from the fuel pump, measure the resistance between its contacts with an ohmmeter. If the resistance is 1.0 ohms, the fuel pump is good.

To remove the fuel pump, disconnect the inlet and outlet hoses and connector, then remove the bracket mounting bolts.

After removing the fuel pump, its operation can be checked by applying a voltage of 12 V to the contacts of its connector.

Installation is carried out in the reverse order of removal.

Checking the fuel pump relay

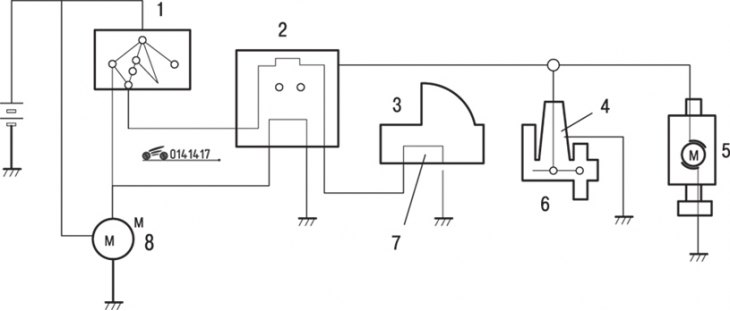

Pic. 14.17. Wiring diagram for the fuel pump power circuit opening relay: 1 - ignition switch; 2 – circuit opening relay; 3 - air flow meter; 4 - heating coil; 5 - fuel pump; 6 - air valve; 7 - fuel pump switch; 8 - starter

The circuit opening relay, mounted on the right side of the bulkhead, supplies current to the fuel pump and air valve only when the engine is started and running (pic. 14.17). After the engine is stopped, the circuit is opened by the fuel pump switch on the air flow meter.

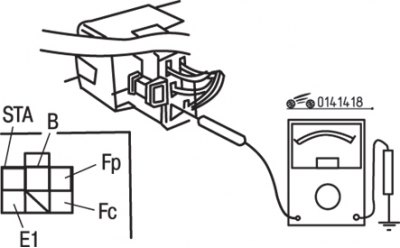

Pic. 14.18. The location of the contacts of the fuel pump circuit opening relay connector: Fp - to the fuel pump; Fc - to the fuel pump switch; B - to the ignition switch; STA - to the ignition switch (ST); E1 - «weight»

With the ignition on, measure the voltage between the contacts on the relay with a voltmeter (pic. 14.18). Voltage between contacts «Fc» And «IN» should be 12 V. Open the air flow meter measuring plate and check that the voltage between «Fr» And «IN» equals 12 V.

Disconnect and connect with «weight» the wire «NT» coils, then have an assistant turn the key in the ignition switch to the engine start position and check that between the contacts «Fr», «IN» And «STA» voltage was 12 volts.

Disconnect the connector from the relay and measure the resistance between the contacts with an ohmmeter «STA» And «E1», which should be within 15–30 ohms, between contacts «IN» And «Fc» – 80–150 ohm and between contacts «IN» And «Fr» equals infinity.

Replace relay if necessary.

Fuel pressure check

A manometer, a tee and a tube are needed to check the pressure.

Disconnect the wire from the negative battery terminal.

Disconnect the fuel hose from the engine side fuel filter and connect a pressure gauge instead.

Connect the wire to the negative terminal of the battery and turn on the ignition.

Connect a piece of wire between the contacts of the control connector of the fuel pump (see fig. 14.15) and check the fuel pressure, which should be 2.5-2.85 kg/cm2.

Start the engine and let it idle, then check that the fuel pressure is between 1.9-2.3 kg/cm2.

If the fuel pressure is not correct, check the fuel filter, pump and pressure regulator.

Switch off the ignition, remove the connecting wire and pressure gauge, then reinstall the fuel hose.