However, when the engine is running at maximum load, the ignition timing should be shifted to the earliest without crossing the detonation combustion boundary.

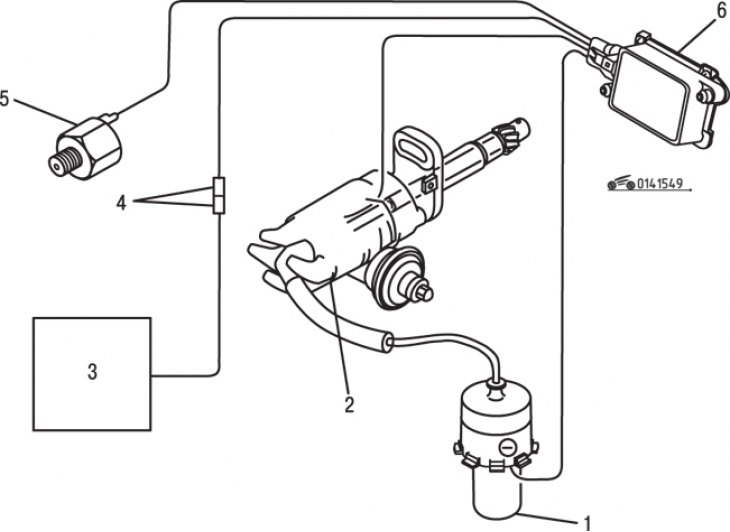

Pic. 15.49. Elements of the fuel detonation control system for cars manufactured in 1986 and 1987: 1 - ignition coil; 2 - ignition distributor; 3 - control unit; 4 - diagnostic socket; 5 - knock sensor; 6 - ignition control unit

The knock control system consists of a knock sensor, an ignition timing control unit and an EGI control unit (pic. 15.49). The knock sensor reacts to the high-frequency oscillations of the cylinder block that occur during detonation and transforms them into electrical signals to the control unit. This information is then compared with the signals obtained during the combustion of the fuel without detonation. When detonation occurs, the ignition timing is shifted to the side of delay by 6°.

At an engine speed of 1650–4500 min-1 or under conditions when the pressure in the intake manifold is below atmospheric pressure, the engine control unit sends a signal to the ignition control unit, which provides a shift in the ignition timing towards an earlier.

Attention! The following test procedure applies only to 1986 and 1987 models, as servicing later models requires special equipment, so you should contact a service station.

Checking the knock sensor

Carefully touch the probe of the voltmeter to the output «1U» on the control unit. At idle, the voltage indicated by the voltmeter should be zero. If the reading is different, check the wire from the control unit to the ignition timing control unit (contact «G»).

Check the ignition timing at idle, then disconnect the diagnostic connector from the control unit. Lightly tap the wall of the receiver with a hammer and check if the ignition timing is shifted towards a later one. If the ignition timing is retarded, reconnect the connector and tap the receiver wall again. Verify that the ignition is not shifted to a later one, which indicates the normal operation of the ignition control unit. Otherwise, the control unit is defective and must be replaced.

If the ignition timing does not lag on the first test, disconnect the diagnostic connector, connect a known-good knock sensor to the connector, and connect it to «weight». Lightly tap on the sensor and check the offset of the ignition timing to a later ignition. If the ignition is shifted to a later one, the sensor that was working is faulty. Otherwise, check the wires from the sensor to the control unit. If the wires are OK, replace the ignition control unit.

Replacing elements

To replace the knock sensor, disconnect the connector and unscrew the sensor from the cylinder block. Installation is carried out in the reverse order of removal.

To replace the ignition control unit, disconnect the wire from the negative terminal of the battery. Disconnect the connector from the block, unscrew the two nuts and remove the block. Installation is carried out in the reverse order of removal.