Disassembly

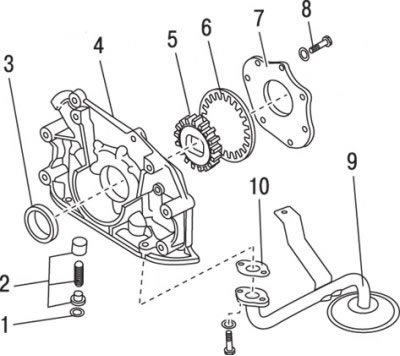

Pic. 3.17. Oil pump details: 1 - retaining ring; 2 - bypass valve of the pressure regulator; 3 - stuffing box; 4 - pump casing; 5 - internal gear; 6 - outer gear; 7 - cover; 8 - screw; 9 - oil receiver; 10 - gasket

Loosen the screws securing the back cover of the pump and remove it (pic. 3.17).

Remove the gears from the pump housing. To do this, you can turn the case over so that the gears fall out by themselves.

Clamp the pump in a soft-jawed vise, remove the circlip, plug, pressure regulator valve plunger and spring.

Examination

Wash the pump parts in solvent.

Check the parts for signs of wear, cracks or other damage.

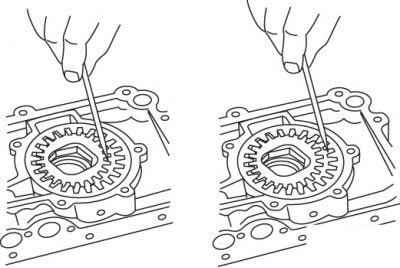

Pic. 3.18. Checking the gap between the inner surface of the teeth (A) and outdoor (IN) gears and a crescent-shaped calibration insert

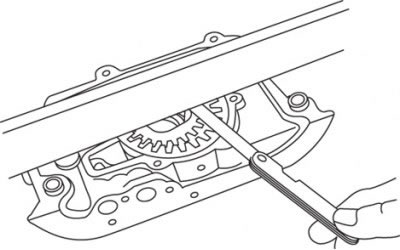

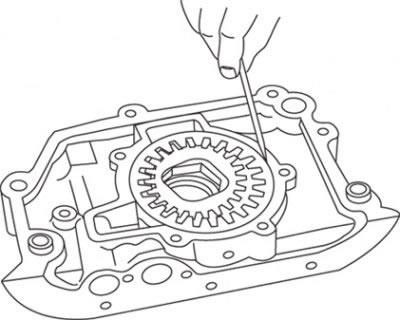

Check the gap between the surface of the teeth of the inner and outer gears and the crescent-shaped calibration insert, the gap between the surface of the outer gear and the housing and the gap between the gear plane and the mating surface of the housing cover (pic. 3.18, 3.19, 3.20).

Pic. 3.19. Checking the gap between the plane of the gears and the mating plane of the housing cover

Pic. 3.20. Checking the clearance between the surface of the outer gear and the housing

Be sure to replace the seal.

Assembly

Install valve assembly with plunger and spring and secure with circlip.

Lubricate and install gears.

Install the back cover of the pump and tighten the screws tightly, lubricating their threads with locking compound (blocking fluid), preventing self-removal.