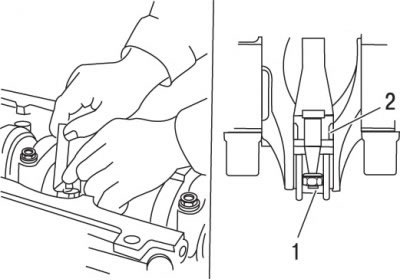

Before removing the connecting rods, check their end play. Install the indicator so that its leg coincides with the axis of the crankshaft and touches the side surface of the cover of the first connecting rod.

Pull the connecting rod towards the rear of the engine, applying maximum effort, and in this position, set the indicator scale to zero. Then move the connecting rod forward to the maximum distance and read the indicator. Axial play is equal to the distance that the connecting rod has moved. If the end play of the connecting rod exceeds the value given in the technical data, it must be replaced. In exactly the same way, measure the end play on the other connecting rods.

Pic. 3.32. Using a feeler gauge for connecting rod end play: 1 – connecting rod cover; 2 - backlash measurement place

Alternatively, you can use another way to measure end play by inserting a feeler gauge between the connecting rod and the surface of the crankshaft thrust flange (pic. 3.32). Increase the thickness of the feeler gauge until there is no play. The amount of axial play is equal to the final thickness of the stylus.

Check for marks on the connecting rods and connecting rod caps. If there are no marks, then mark them so that the number of marks corresponds to the number of the cylinder in which this connecting rod is installed.

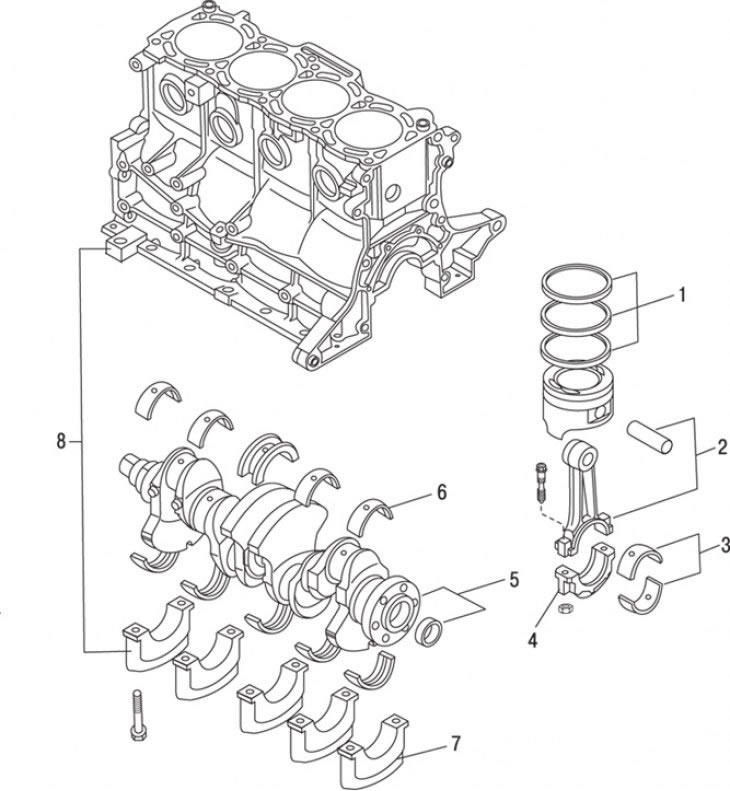

Pic. 3.33. Cylinder block, crankshaft, liners and connecting rods: 1 - piston rings; 2 - connecting rod and piston pin; 3 - shells of the connecting rod bearing; 4 - connecting rod cover; 5 - crankshaft and needle bearing; 6 - insert of the main bearing; 7 – a cover of the radical bearing; 8 - cylinder block

Loosen the nuts by backing them out 1-2 turns. Remove the cover from the connecting rod of the first cylinder together with the connecting rod bearing (pic. 3.33). Do not remove the connecting rod bearing from the cover. Put pieces of rubber or plastic hoses on the connecting rod cap bolts so as not to damage the crankshaft journal and cylinder walls when removing the connecting rod, push the piston assembly with the connecting rod through the top of the cylinder. To do this, use a wooden spacer, resting it on the upper connecting rod bearing. If there is resistance to piston removal, recheck that the collar has been removed from the top of the cylinder.

Repeat the procedure for the remaining cylinders. After the pistons with connecting rods are removed from the cylinders, remove the connecting rod caps, remove the connecting rod bearings, reinstall the caps and tighten the nuts by hand.

Connecting rod bearings are recommended to be removed only before assembly, thus preventing accidental damage to their working surfaces.