Lay out the pistons with connecting rods and new piston rings in such order that the set of rings corresponds to the given cylinder, on which the clearance in the lock will be measured.

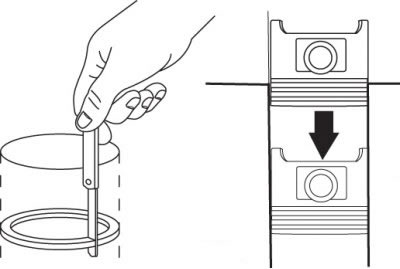

Pic. 3.46. Piston ring gap measurement

Insert the upper ring into the first cylinder and push the piston head inward so that the ring inside the cylinder becomes perpendicular to its axis. The ring must be at the bottom of the cylinder in the position corresponding to the bottom dead center. Piston ring gap is measured with a feeler gauge (pic. 3.46). Compare the result with the required value.

If the clearance is greater or less than specified, repeat the measurement to ensure that the ring can be installed.

If the gap is too small, then it must be increased, because otherwise, during the operation of the engine, the ends of the ring are connected, which can cause serious damage. The gap in the piston ring lock can be increased by carefully filing the ends with a thin file. Clamp the file in a vise with soft jaws and carefully move the ring along it, removing excess material.

The gap may exceed the specified, but should be no more than 1 mm.

The measurement should be repeated to ensure the fit of the ring.

Repeat the measurements for each ring installed in the first cylinder, as well as for the remaining rings installed in other cylinders.

After measuring the gaps in the locks of the rings and adjusting them, the rings can be installed on the pistons.

The oil scraper ring is installed first (the bottom of the piston).

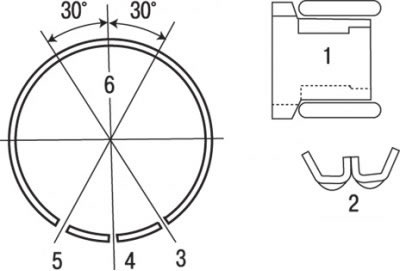

Pic. 3.47. The location of the elements of the oil scraper ring and locks: 1 - oil scraper ring; 2 - oil scraper ring (expander); 3 - bottom guide; 4 - expander; 5 - top guide; 6 - piston pin

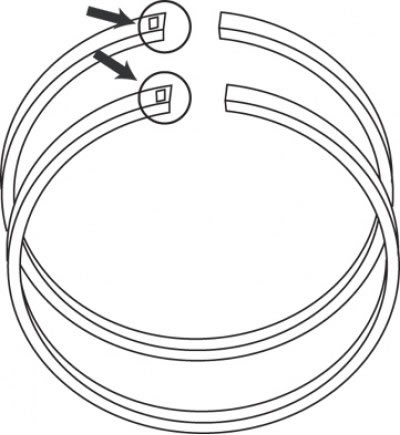

Pic. 3.48. Installing the elements of the oil scraper ring

This ring is made up of three elements. Install spacer/expander in groove (pic. 3.47), then install the lower oil ring guide. When installing the guides, do not use the device for installing rings, as they may break. Insert one end of the guide into the groove of the piston between the separator and the horizontal groove platform and, holding it firmly, insert the other end of the ring into the groove with your finger (pic. 3.48). Install the second guide in the same way.

After installing all the elements of the oil scraper ring, make sure that the upper and lower guides turn freely in the groove. Arrange locks of an oil scraper ring according to fig. 3.47.

The middle ring is installed next. It has a label stamped on it «R», which should be directed towards the bottom of the piston.

Attention! Always follow the instructions on the piston ring packaging, different manufacturers may have different designations.

Attention! Do not confuse the top and bottom compression rings as they have different cross-sectional profiles.

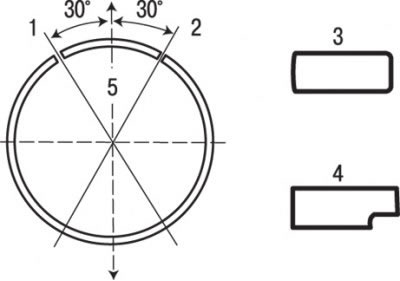

Pic. 3.49. The location of the marks on the compression piston rings

Install the piston ring installer, make sure the marks are facing the piston crown and move the appropriate ring into the middle groove of the piston (pic. 3.49). Do not spread the ends of the ring a distance greater than is required for its passage over the piston. Instead of a fixture, you can use metal strips.

Pic. 3.50. The position of the compression rings and the location of their locks: 1 - lock of the upper compression ring; 2 - lock of the lower compression ring; 3 - upper compression ring; 4 - lower compression ring; 5 - piston pin

Install the top compression ring in the same way. Make sure the labels are pointing up. Do not interchange the top and bottom compression rings. Arrange the locks of the rings in accordance with fig. 3.50.