Checks should first be carried out to find out the causes of malfunctions in the hydraulic clutch system. First you need to check the level of the working fluid in the tank. When the level decreases, add fluid and visually check for leaks along the entire line of the system. To check the completeness of the clutch disengagement, measure the full stroke of the slave cylinder. When you press the clutch pedal, the rod should extend to its full length.

Clutch pedal installation height

Measure the distance from the floor of the body to the surface of the clutch pedal pad.

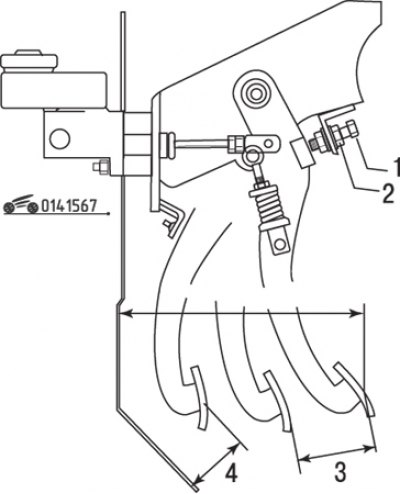

Pic. 15.67. Clutch pedal position adjustment: 1 - limiter bolt; 2 - locknut; 3 - free travel of the clutch pedal; 4 - distance to the floor with the clutch fully disengaged

If the result is not the desired value, loosen the pedal travel stop jam nut and turn the travel stop bolt (pic. 15.67) until the pedal is in the desired position (on later vehicles, the limiter bolt may be combined with the switch on the clutch pedal).

Tighten locknut.

Free play and clutch pedal height

Depress the pedal by hand and measure the free play (distance from the starting position to the appearance of noticeable resistance to the pedal stroke).

If the result is not as desired, loosen the clutch master cylinder rod jam nut and rotate the rod until the desired free play is obtained.

Check the height of the fully depressed clutch pedal (clutch disengagement height).

Tighten locknut.

Clutch Master Cylinder

Removing

Disconnect the wire from the negative battery terminal.

On some vehicles it may be necessary to remove the relay carrier.

Disconnect the hydraulic tube from the clutch master cylinder. When unscrewing the fitting, it is recommended to hold the tube with a ring wrench, which will prevent it from twisting together with the fitting. Pre-substitute a container or place a rag, as when the tube is disconnected, the working fluid may spill.

Attention! Do not allow brake fluid to get on the car's paintwork, as it will lose its luster.

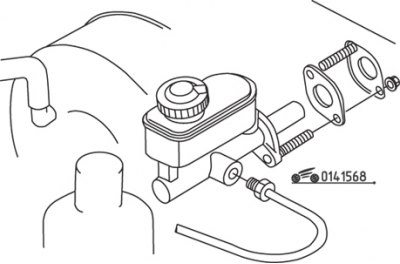

Pic. 15.68. Clutch Master Cylinder Fasteners

Turn away nuts of fastening of the main cylinder to a wall of a motor compartment. One nut is located on the wall of the engine compartment, and the second is under the instrument panel on the brake pedal bracket (pic. 15.68).

Carefully remove the cylinder from the rod and take it out through the wall of the engine compartment.

Installation

Carefully insert the cylinder through the wall of the engine compartment and insert the rod. Tighten the nuts by hand-tightening.

Attach the hydraulic actuator tube to the clutch master cylinder by slightly manipulating the cylinder so that the fitting on the tube is threaded into the threaded hole in the cylinder. Be careful not to damage the thread when screwing in the fitting.

Tighten the mounting nuts and hydraulic drive tube fitting securely.

Fill the clutch reservoir with DOT-3 approved brake fluid and bleed the hydraulic actuator.

Connect the cable to the negative battery terminal and check clutch operation before driving.

Clutch slave cylinder

Removing

Disconnect the wire from the negative battery terminal.

Raise the car and secure it on stands.

Disconnect the hydraulic actuator tube from the clutch slave cylinder. When unscrewing the fitting, it is recommended to hold the tube with a spanner to prevent twisting of the tube together with the fitting. Pre-substitute a container or place a rag, as when the tube is disconnected, the working fluid may spill.

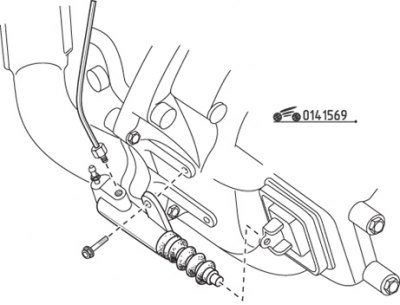

Pic. 15.69. Elements of fastening of the working cylinder of coupling

Loosen the clutch slave cylinder bolts and remove it (pic. 15.69).

Installation

Install the slave cylinder on the clutch housing and make sure that the cylinder rod has entered the recess of the clutch release fork, tighten the mounting bolts.

Connect the hydraulic drive tube to the cylinder and tighten the fitting, being careful not to damage the threads.

Fill the clutch master cylinder reservoir with DOT-3 approved brake fluid.

Bleed air from hydraulic drive.

Connect the cable to the negative battery terminal and check clutch operation before driving.

Bleeding the hydraulic clutch (pumping)

Bleeding of air must be carried out when removing any element of the hydraulic drive system or when the fluid level drops, at which air enters the clutch cylinder. The work is similar to removing air from the brake system (pumping).

Fill the clutch master cylinder reservoir with fresh DOT-3 brake fluid.

Attention! When removing air, it is not allowed to use a liquid that was in use or stored for a long time in an open container.

To access the slave cylinder, raise the vehicle and secure it on stands.

Remove the dust cap from the bleeder fitting and put a piece of plastic hose on the fitting. Place the end of the hose in a clean vessel with brake fluid filled to a level of about 5 cm. The end of the hose must be immersed in the liquid.

Have an assistant depress the clutch pedal and hold it down. Unscrew the bleed valve on the working cylinder so that the liquid flows into the vessel. Close the bleeder while fluid is escaping. After that, ask the assistant to release the pedal.

Repeat this cycle until the air is completely removed from the system, as evidenced by the absence of bubbles in the collection container and in the fluid flowing through the hose each time the pedal is depressed. Keep an eye on the fluid level in the supply tank. If the level drops too low, air can be sucked into the system, necessitating re-priming.

Install the dust cap and lower the vehicle. Check clutch operation.