2. Visually inspect the block for cracks and corrosion. Repair stripped threads in holes. It is highly recommended to check the tightness of the cylinder block in car service workshops that have the appropriate equipment. If defects are found, repair or replace the unit.

3. Check for scratches and burrs on the inner surfaces of the cylinders.

4. Measure the inner diameter of the cylinder at the top (right under the ridge), in the middle and in the lower part parallel to the axis of the crankshaft. Then take measurements at the same levels, but in a direction perpendicular to the axis of the crankshaft. Compare the measurement results with the values given in the manual. If there are severe scuffs and scratches on the surfaces of the cylinders, or the ovality and taper of the cylinders exceed the established limits, then the block must be handed over to the workshop for boring and honing. After repair, pistons and rings of repair sizes will be needed.

5. If the condition of the cylinders is acceptable, the wear of the cylinder and the clearance between the cylinder and the piston do not exceed the established norms, then boring is not required. The only necessary operation is honing.

6. Install the crankshaft main bearing caps before honing (without bearings), tighten the bolts to the specified torque.

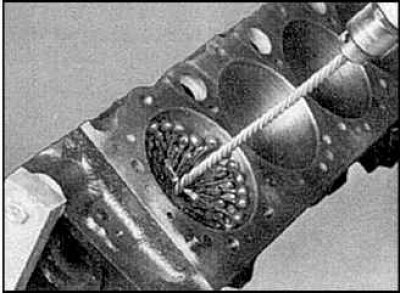

7. For honing, you will need a special device with fine grinding heads, a large amount of oil, rags and an electric drill. Clamp the tool into the electric drill, attach the grinding heads and insert the tool into the first cylinder. Lubricate the surface of the cylinder well with oil, turn on the electric drill and periodically move it up and down in the cylinder.

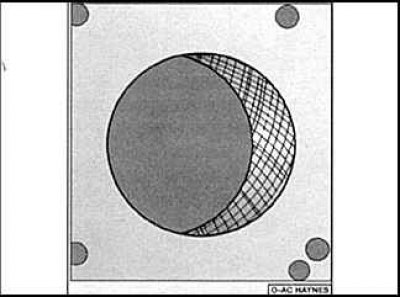

8. In this case, a structure of thin lines intersecting at an angle of about 60°should form on the surface of the cylinder walls.

9. Lubricate the surface of the cylinder liberally at all times. Do not remove the tool during rotation. After turning off the drill, continue to move it up and down until it comes to a complete stop, then squeeze the legs of the tool with the grinding heads and remove it from the cylinder. Wipe the oil off the cylinder and repeat the operation on the remaining cylinders. If the device is not available or there is no desire to do honing yourself, then this operation can be done in workshops for a reasonable fee. Satisfactory results are obtained when using an emery wheel mounted on an electric drill, or even when performing the operation manually with sandpaper.

10. After honing, chamfer the upper edges of the cylinder with a small file to prevent the rings from seizing when the piston is installed.

11. The whole block should be washed again with warm water and detergent to remove the abrasive residue from honing. Brush all channels and rinse with running water. After flushing, dry the cylinder block and apply spindle oil to all machined surfaces. Before assembly, store the unit under a plastic cover.