At home, the following work is possible: disassembly of the cylinder head, flushing and checking it, reassembly and delivery to the dealer's car service or to specialized workshops for valve repair.

In the car service or in specialized workshops, the following types of work are performed: removing springs and valves, grinding or replacing valves and guide bushings, checking and replacing springs, retaining rings and crackers (as needed), replacement of valve stem seals, overhaul of valve parts, checking the height of the spring in a free state. If the deviation from the plane exceeds the norm, the head of the block is polished.

After the inspection and repair of valves and their parts by experienced personnel, the cylinder head is completely restored. Before installing the block head, flush it again to remove abrasive residue from grinding the head or lapping the valves. If possible, blow out all channels and openings with compressed air.

Examination

Valves

1. Carefully inspect the valve heads, replace worn valves if necessary.

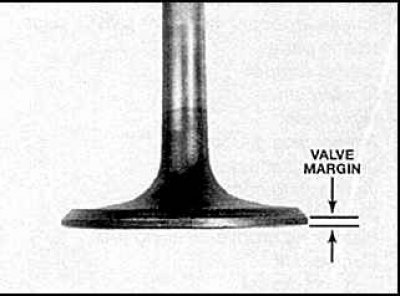

2. Measure the height of the valve head above the chamfer, replace the valve if necessary.

Valve elements

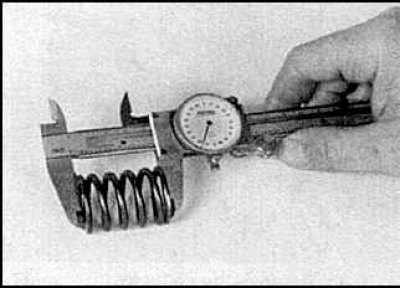

3. Inspect the valve springs and measure the length of each, replace if necessary.

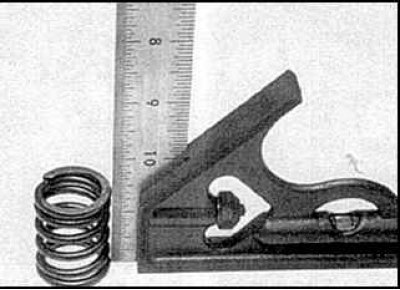

4. Check that the springs are straight, if necessary, replace all the springs at the same time.

5. Inspect the spring seats and cups for cracks and wear, and replace if necessary.

Valve grinding

If the chamfers of the valves and seats have slight wear, or new valves are installed on non-worn seats, then the valves must be lapped to the seats. The lapping operation is performed as follows.

1. Apply a small amount of coarse abrasive paste to the face of the seat.

2. Insert the valve into the guide sleeve and, turning and pressing the valve, lap it against the seat. To perform this work, you will need a device in the form of a tube with a piece of rubber hose inserted inside. Lapping can also be done with an electric drill by inserting this device into the chuck. While lapping, periodically raise the valve to check the result and redistribute the lapping material.

3. When a smooth, continuous band forms on the valve head or seat bevel, remove any remaining coarse abrasive paste and continue lapping with fine paste.

4. After lapping all valves to their seats, thoroughly wash the lapped areas with kerosene to remove abrasive residues, wipe with a rag and blow (if possible) compressed air. Residues of abrasive in the head of the block can cause increased wear of parts.

It should be noted that excessive lapping of old valves may disturb the seating and make it unacceptable, or if new valves are lapped onto old seats, excessive lapping may result in "pockets".