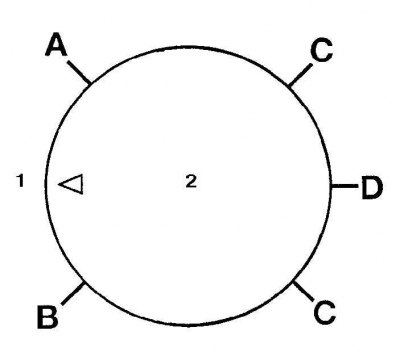

Location of bearing end clearances

1. Engine front

2. Piston top

A. Upper compression ring clearance

B. Second compression ring clearance

C. Oil ring clearances

D. Expansion ring gap

Checking the lubrication clearance of connecting rod bearings

1. Clean the upper connecting rod bearing and install it on the connecting rod. The lubrication holes of the connecting rod and bushing must be aligned.

2. Clean the second bearing and install it in the connecting rod cap.

3. Position the piston ring end gaps as shown.

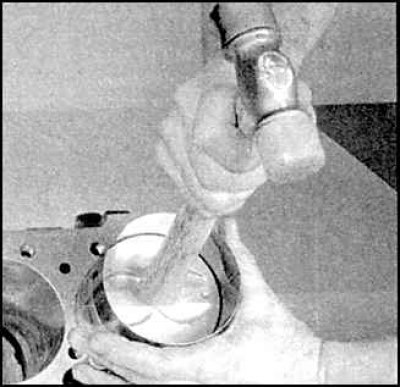

4. Lubricate the pistons and rings and compress the piston rings with a piston ring compressor.

5. Rotate the crankshaft so that the connecting rod bearing of the first cylinder is in the bottom dead center position, and lubricate the cylinder walls.

6. Check that the mark on the top of the piston is facing forward.

7. Press down on the piston and install it into the cylinder.

8. An internal micrometer or other special device can be used to measure the lubrication gap, but the most accurate and easiest method is to use a special plastic gauge.

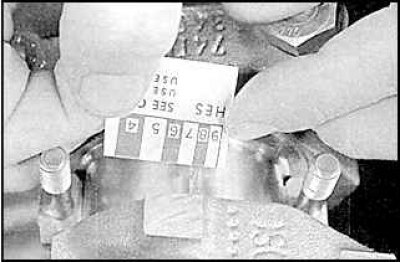

9. After installing the piston in the cylinder, tighten the connecting rod cap bolts and check the connecting rod bearing oil clearance. Lay a piece of plastic on each of the connecting rod bearings parallel to the axis of the crankshaft.

10. Compare the width of the crushed film with a special scale.

11. If the clearance is not correct, the wrong size bushings may have been installed.

Final installation of pistons and connecting rods

1. Remove all traces of plastic. Check that the surface of the bearings is absolutely clean and lubricate them with engine oil.

2. Install the connecting rod on the shaft journal, install the connecting rod cap and tighten the nuts to the correct torque.

3. The rest of the connecting rods are installed in the same way.

4. After installing all the connecting rods, rotate the crankshaft several times and check for ease of movement.

5. Check the end play of the connecting rods.