Tools needed for troubleshooting

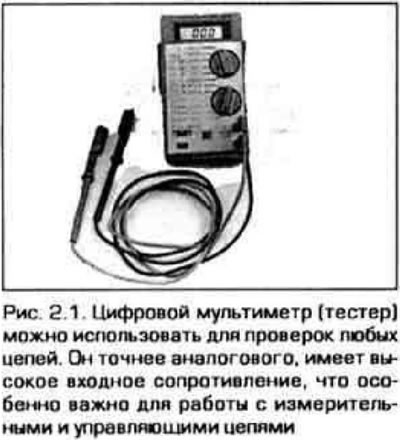

1. A digital multimeter is required to test items related to fuel injection and emissions control systems (pic. 2.1). A digital tester should be preferred over its analog predecessor for the following reasons. An analog tester is not able to detect and show changes in voltage, resistance, or current in hundredths or thousandths, as a digital instrument can. Another advantage of digital instruments is their large input impedance (impedance), which can be several million ohms. Since the voltmeter is connected in parallel with the circuit under test, it is important that the current does not branch into the circuit of the device and does not distort the measurement results. When testing power targets with low resistance and a sufficiently high voltage level, for example, 9-12 V, the resistance of the device does not play a significant role. But when working with high-resistance circuits and low voltages, characteristic of measuring circuits, a large resistance of the device can be very useful. For example, when measuring an oxygen sensor signal, even a voltage of 1 V can be significant in troubleshooting.

2. Hand scanners (pic. 2.2) are the most effective tool for analyzing engine control systems of modern models. The measure of the scanner must match your car - model and year of manufacture. Sometimes the design of the scanner provides for the installation of adjacent cartridges designed for certain manufacturers (Ford. G.M. Chrysler, etc.). Some manufacturers specialize in markets - Asia, Europe, North America, etc.

3. Models since 1996 are equipped with a more advanced OBD-II on-board diagnostic system. To read fault codes in this system, you need a scanner (code reader), specially designed for this system. If there is no scanner and it is not possible to get it, then the system can be diagnosed only at a service station that has such equipment.

OBD-I system (days of models of early releases to 1995)

General information

Note. Major faults are listed in the Troubleshooting section at the beginning of the book.

4. On-board computer (BEU) has a built-in self-diagnosis system or OBD (On-Board Diagnostics) - on-board diagnostics. which detects malfunctions of the system sensors and informs the driver about this with the CHECK ENGINE signal light (check the engine). When a malfunction occurs, the diagnostic system generates a malfunction code and places it in the computer's memory. The fault code is stored until it is forcibly removed from memory or the fault is corrected.

5. When the ignition is turned on, the CHECK ENGINE light should come on. This means that the system is checking if the alarm is working. After starting the engine, the light should go out. If the light does not go out, then the diagnostic system has detected a malfunction.

Reading trouble codes

6. To access the diagnostic system, first find the diagnostic connector, which should be located on the left (from the driver's side) side of the engine compartment next to the battery. Depending on the model, engine, transmission, etc. one of two types of diagnostic connector can be installed on the car (pic. 2.6, a, b). Connect the STI and GND pins of the connector with a short jumper. If desired, you can connect an analog voltmeter or test light to the STO contact (connect the second wire of a voltmeter or light bulb to ground). Fault codes can be read by fluctuations in the voltmeter needle or by flashing a light bulb. The CHECK ENGINE light will flash in the same way.

7. Make sure. that the battery voltage is greater than 11 volts, that the transmission is in neutral, electrical consumers are off, the throttle is closed, and that the engine is at operating temperature. After that, turn on the ignition, but do not start the engine.

8. The fault code is determined by the number of flashes of the CHECK ENGINE light bulb (or control light, if connected). If there are no trouble codes in the memory, the light will turn on for a while and then turn off. If there are fault codes in the memory, then the light will show the first digit of the code with long flashes, and the second digit of the code with short ones. For example, code 34 (idle control valve malfunction) reproduced by a series of three long flashes and four short ones.

Note. If the move consists of one digit, then the light will blink only with short flashes.

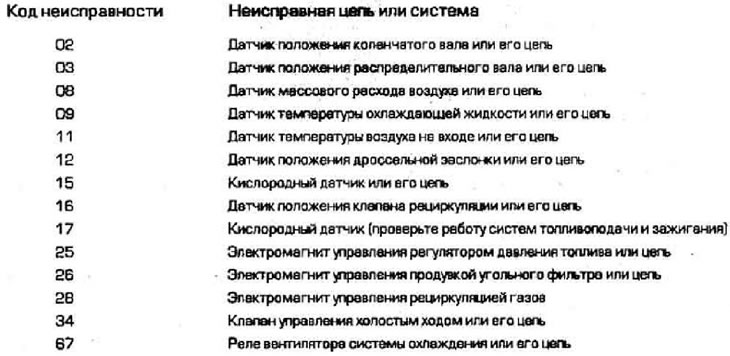

9. Below is a table that lists the stakes and their corresponding faults.

OBD-I system codes (two-digit codes)

OBD-I system codes (three-digit codes)

Deleting codes

10. At the end of the code check, remove the jumper from the diagnostic connector and close the connector with a cover. Check the system or circuit where the problem is found and correct it.

11. After troubleshooting, the trouble code can be given. To do this, disconnect the negative cable from the battery, press the brake pedal and keep it pressed for at least 5 seconds.

12. After clearing the codes, test drive and see if the problem reappears.

OBD II system (release models since 1996)

General information

Note 1. Major faults are listed in section troubleshooting at the beginning of the book.

Note 2: This is not a complete list of trouble codes that are generated by the OBD-fl system. To read the codes in this system, you need special equipment. The text only lists codes that are common to all vehicles manufactured since 1996 and equipped with an OBD-II diagnostic system. This list does not include colas included in the diagnostic system by specific manufacturers. For additional fault codes entered by the manufacturer, you can ask your dealer.

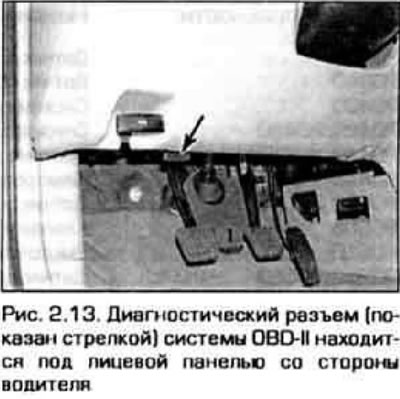

13. Starting in 1994, the Ford Motor Company began equipping its vehicles with a modified OBD-II diagnostic system. This system monitors the emission control system, detects system malfunctions, and stores information about malfunctions in the computer's memory. The diagnostic system also checks the sensors of the engine management system and actuators, determines and calculates the vehicle's operating cycles, updates information and clears codes. Access to the OBD-II diagnostic system is only possible using a scanner that is connected to the system's 16-pin diagnostic connector. This connector is located under the dashboard on the driver's side (pic. 2.13).

Note. Although Ford launched the OBD-II system back in 1994, the models described in this book did not introduce the system until 1996.

14. The BEU is the brain of the system. located under the front foam drink from the front passenger side. The unit receives information from numerous sensors, as well as from other electrical devices (switches. relays, actuators). Based on the information received, the BEU generates output signals for controlling actuators - relays, electromagnets, etc. The BEU is programmed to optimize the traction and dynamic qualities of the car, its efficiency and minimize harmful emissions.

15. In connection with that. that the DBD4I system has an extended warranty, it is not recommended to replace the BEU or sensors of the system yourself during the warranty period, if you do not want to lose it.

Reading trouble codes in the OBD-II system

16. The OBD-II system will illuminate a warning light on the instrument panel after it detects the same fault in the next two consecutive work cycles. The lamp will be on until the system detects this malfunction in three successive cycles. Since special equipment is needed to reset the fault signal, it is recommended that the system be periodically checked by a specialized service station.

17. To extract diagnostic codes, a special scanner is required that connects to the system's diagnostic connector.

Deleting codes

18. To delete codes from the BEU memory, connect the scanner to the diagnostic connector and select the CLEARING CODES mode in the device menu (deleting codes). Then follow the scanner manufacturer's instructions.

Caution: To clear codes, DO NOT DISCONNECT the battery. By turning off the BEU power, you will erase the current information about the state of the engine and the control unit will again have to extract this information. While this is happening, the engine will run intermittently.

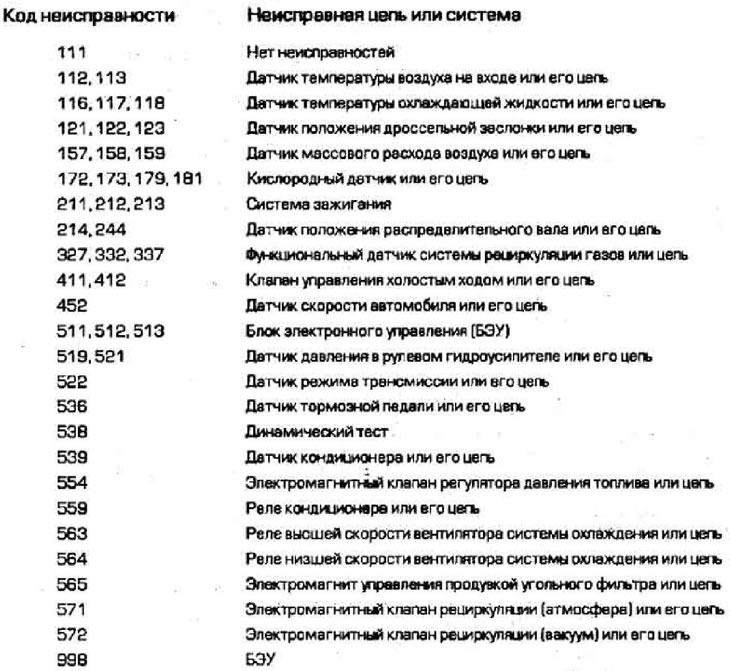

OBD-II system codes

System sensors (OBD-I and OBD-II)

19. The oxygen sensor generates a signal in the form of a voltage, which depends on the difference in the oxygen content in the exhaust gases and in the surrounding air.

20. Crankshaft position sensor 1 - on some models located in the ignition distributor. Notifies the BEU about the position and speed of the crankshaft. The ECU uses this information to calculate fuel cycling and ignition timing.

21. Crankshaft position sensor 2 is installed on late models. They perform the same functions as sensor 1, but are not located in the distributor, but next to the crankshaft pulley.

22. The camshaft position sensor gives a signal by which the ECU determines the position of piston No. 1 to control the fuel injection sequence.

23. Coolant temperature sensor - gives a signal in the form of voltage, according to which the ECU correlates the composition of the mixture, ignition timing and controls the operation of the gas recirculation system.

24. Inlet air temperature sensor - gives the BEU information about the air temperature at the inlet to the air cleaner. The BEU uses the sensor information to adjust the fuel supply, ignition timing and to control the vapor recirculation system.

25. Throttle position sensor - gives the BEU information about the position and movement of the throttle. Based on the signal from the sensor, the BEU determines whether the throttle valve is in the closed, fully open or intermediate static position.

26. Mass air flow sensor - measures the mass of air entering the engine cylinders. The information is used by the BEU to calculate the fuel supply.

27. Knock sensor - detects the presence of detonation and notifies the BEU about it. The control unit, having received a knock signal, begins to reduce the ignition timing until the knock disappears.

28. The vehicle speed sensor transmits information about the vehicle speed to the BEU.

29. Gas recirculation valve position sensor - informs the ECU about the position of the recirculation valve.

30. Fuel tank pressure sensor - is part of the fuel vapor control system and transmits information about the fuel vapor pressure in the tank to the BEU. BEU uses evil information to control the actuators of the carbon filter purge system.

31. Power steering pressure sensor - contact sensor (switch) is designed to increase pressure in the transmission control system when maneuvering a car in cramped conditions at low speed.

32. Transmission sensors - in addition to the speed of the vehicle, the BEU receives signals about the rotational speed of the primary and intermediate shafts of the transmission or parts connected to them.

33. Compressor switch-on sensor - when the compressor is turned on, the sensor contacts close and send a signal to the ECU. The control unit interprets the signal as an increase in engine load and increases the idle speed accordingly so that the engine does not stall.

34. Brake pedal sensor - combined with the brake light switch. When the brake is pressed, the BEU receives a signal, according to which the BEU turns off the mode "Cruise control" (if it's on), reduces the ignition timing and changes the cyclic fuel supply for the period of deceleration of the car.

Executive devices of the system (OBD-I and OBD-II)

35. Fuel injectors - BEU opens the injectors in turn, in accordance with the order of operation of the cylinders. In addition, the BEU controls the duration of the nozzle opening (control pulse width), which determines the amount of fuel supplied to the cylinder per cycle.

36. Ignition control unit - the unit operates under the control of the BEU. It controls the current in the primary winding of the coil (coils) ignition and sets the required advance according to the signals of the ECU. On some models, the ignition control unit is located in the distributor, on other models it is located separately in the engine compartment. For more information about the ignition control unit, see chapter 5.

37. Idle Air Control Valve - Controls the extra air flow around the throttle when it is in the idle position. The valve opening degree is determined by the BEU.

38. Solenoid valve for purge of the coal filter - the coal filter, which contains fuel vapors, is blown under certain engine operating conditions. Fuel vapors enter the intake manifold and further into the engine cylinders, where they burn out in the usual way.