Examination

2. Remove the sensor and inspect it. Look for dirt on the intake screen, especially if the vehicle is equipped with an OBD-I diagnostic system and if the system has detected a fault code 158. If the screen is clogged, clean it. On 1993 to 1997 V-twin engines, push the choke on the intake side and make sure it moves back and forth smoothly without sticking. Install the sensor in place and make sure that its seating surfaces are well sealed and do not let air through.

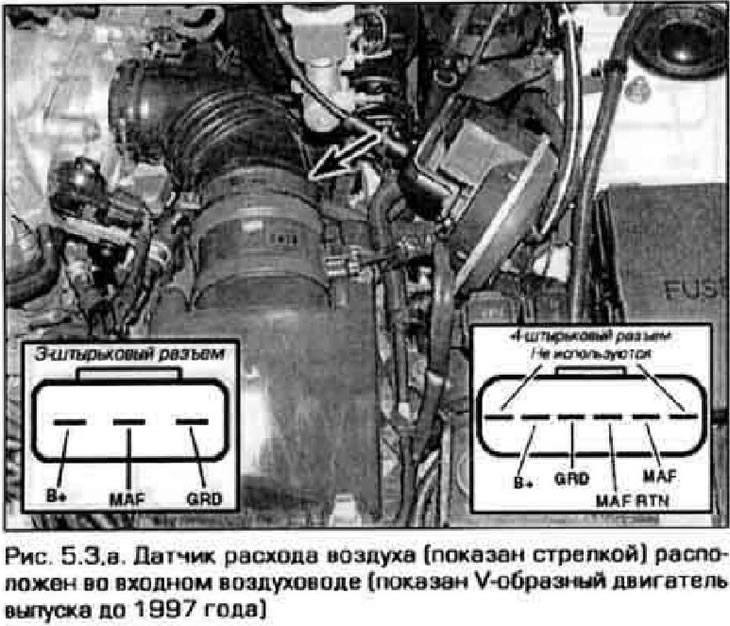

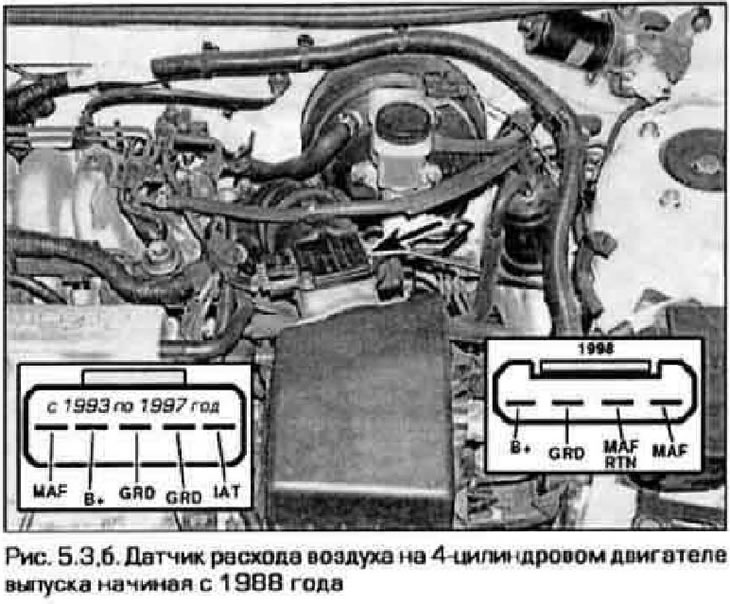

3. Connect the voltmeter with thin probes from the outside of the connector to the contacts B + and GRD (pic. 5.3, a, b). Turn on the ignition. The voltmeter should show battery voltage. If there is no voltage, disconnect the connector and check the integrity of the ground connection to the GRD contact.

- A) No voltage and no earth connection: check the ground circuit.

- b) No voltage, mass connected: check the purpose of the power supply.

Repair the chain if necessary.

All 4-cylinder and V-engines manufactured since 1998

4. Measure the voltage from the outside of the connector on the MAF contact - first with the engine off, then with the engine idling (see fig. 5.3.6).

5. If the sensor has a 3-pin connector, the voltage when the engine is not running should be in the range of 1.0-15 V, and when idling - 1.5-5.0 V.

6. If the sensor has a 4-pin connector, the voltage when the engine is not running should be about zero, and when idling - 0.6-0.7 V (on engines manufactured since 1998. (0.6-1.1V).

7. Raise the engine speed and give it a boost. how the voltage changes. It should gradually increase to about 2.0 V. Voltage spikes indicate that the sensor is faulty.

V-engines produced from 1993 to 1997

8. Disconnect the air duct from the sensor (to do this, push the shutter inside the sensor). Turn on the ignition, but do not start the engine.

9. Measure the voltage at the MAE pin on the outside of the connector (connect the second probe of the voltmeter to the GND pin) (see fig. 5.3a). With the damper closed, the voltage should be 4.0 V. When the damper moves inside the sensor, the voltage should decrease as follows:

- A) 1/4 open - 2.4 V

- b) Opened at 1/2-1.6S

- V) Opened on 3/4-0 Q 8

- G) Fully open - 0.4V

All models

10. Replace the duct (if it was taken).

Note. If there are problems with engine controllability and the tests described above do not reveal any malfunction, have the sensor checked by a specialist. Not all sensor faults can be detected with a voltmeter. The BEU detects this kind of malfunction and the diagnostic system can store the corresponding code.

Replacement

11. Disconnect the negative cable from the battery.

Caution: If your vehicle's audio system is equipped with an anti-theft protection, make sure you know the unlock code before disconnecting the battery.

12. Disconnect the electrical connector from the air flow sensor.

13. Turn away nuts or bolts and remove the gauge (pic. 5.13).

14. Installation is carried out in reverse order.