Examination

1. The throttle position sensor is mounted on the throttle body and attached to the throttle shaft. In accordance with the angle of rotation of the damper, the BEU regulates the supply of fuel to the engine cylinders. A malfunction or loose sensor mount can cause unstable engine operation, because the ECU perceives sensor shaking as damper movement. The diagnostic system detects a malfunction of the throttle sensor and generates the appropriate code (see paragraph 2).

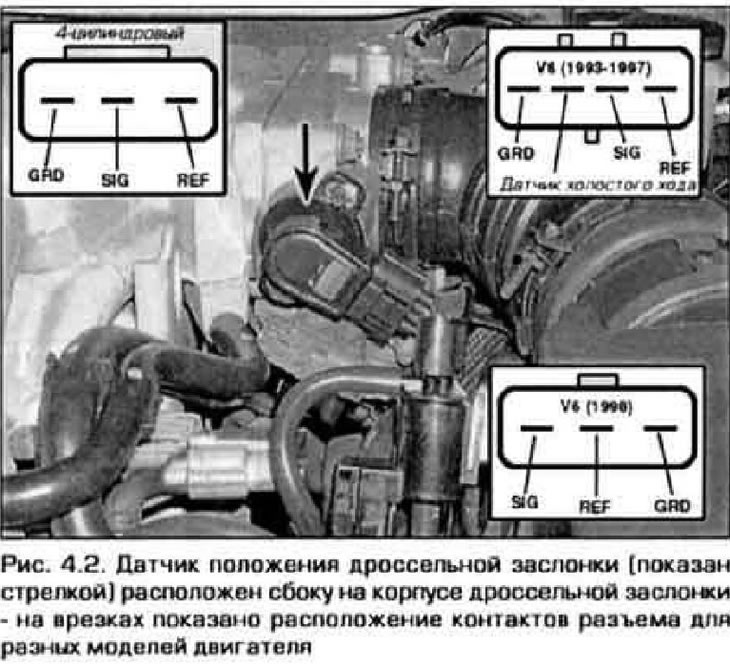

2. Check the voltage supply from the BEU to the sensor. To do this, disconnect the electrical connector of the sensor and connect a voltmeter to the REF contacts (+) and GND (-) (pic. 4.2). With the ignition on (engine not running) the voltmeter should show approximately 5.0 V. If there is no voltage, then either there is a break in the wiring from the BCU to the sensor, or the BEU is faulty.

3. Now check the sensor potentiometer. Connect the sensor connector and connect a voltmeter to the pins of the SIG connector (+) and GNO (-) on the back side (using thin probes or needles). Turn on the ignition (do not start the engine). Fully close the damper. The voltage at the sensor contacts should be within 0.5-1.0 V. Now slowly open the damper and watch the voltage change - it should increase slowly and smoothly. With the damper fully open, the voltage should stop at 3.5-5.0 V.

4. On 1993 4-cylinder engines, the throttle position sensor is structurally integrated into the throttle body and cannot be replaced separately from it. Sensor adjustment is not possible on these models. On all other models, the sensor can be adjusted. If, when checking the sensor, the signal voltage does not change as indicated in paragraph 3, try adjusting the sensor. If the adjustment does not help, replace the sensor.

Adjustment

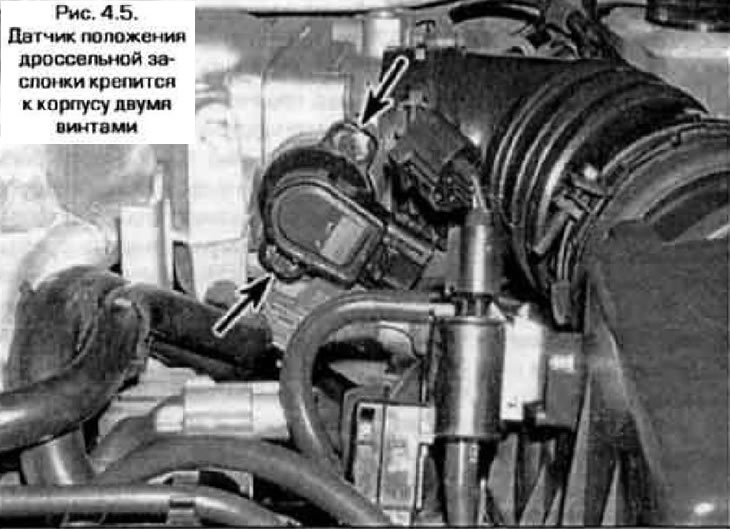

5. Loosen the sensor fixing screws (pic. 4.5).

6. Connect a voltmeter to the SIG and GND pins of the sensor connector (see fig. 4.2).

7. Set the damper to the fully closed position and rotate the sensor until the signal voltage is between 0.5-1.0 V. Tighten the sensor mounting screws.

8. Rotate damper to fully open position. The signal voltage should be in the range of 3.5-5.0 V.

9. If you cannot obtain the desired voltage values in both positions of the damper, replace the sensor.

Replacement

10. This procedure is valid for all models except 1993 4-cylinder engines. On engines of this model, the sensor is made integral with the damper body and can only be replaced as an assembly with the body.

11. Disconnect the sensor electrical connector. Loosen the mounting screws and remove the sensor from the damper body (see fig. 4.5).

12. The sensor is installed in the reverse order of removal. Align the tabs on the sensor body with the cutouts on the damper body. Screw in the screws, adjust the position of the sensor as above, then finally tighten the screws.