Examination

1. An oxygen sensor monitors the oxygen content in the exhaust stream. The oxygen contained in the exhaust gases reacts with the sensor, which leads to a change in the sensor signal voltage ranging from 0.1 V (too much oxygen, lean mixture) up to 0.9 V (little oxygen, rich mixture). BEU receives a signal from the sensor and calculates the ratio of fuel and air in the working mixture. Correction of this ratio is carried out by changing the duration of the open state of the fuel injectors. The ideal working mixture is considered to be 14.7 parts of air and 1 part of fuel. With this ratio of air and fuel, almost complete combustion of the fuel is achieved, which allows the catalytic converter to operate at maximum efficiency. BEU strives to maintain the composition of the working mixture at an optimal level under all engine operating conditions. The OBD-II diagnostic system contains at least two oxygen sensors: the primary sensor is located upstream of the converter and the secondary one is located behind the converter. Late production V-engine models even have four oxygen sensors. Comparing the composition of gases before and after the converter, the sensors allow you to monitor the efficiency of its work.

2. Until the oxygen sensor reaches operating temperature (around 300°C), it does not generate a signal. Therefore, when the engine is warming up, the BEU operates in the open-loop mode.

3. If the engine has reached operating temperature and (or) more than 2 minutes have passed since the start, and the oxygen sensor voltage does not change and does not exceed 0.45 V at an engine speed of 1500 rpm or higher, a DTC will be registered in the diagnostic unit. Additional codes may also appear in the event of a malfunction in the sensor heating circuit.

4. If the oxygen sensor or its target fails, the control unit starts to work in open-loop mode, i.e. the composition of the working mixture is determined by the program stored in the BEU memory and is not corrected in accordance with the oxygen sensor signal.

5. Normal operation of the oxygen sensor depends on four conditions:

- A) Electrical circuit - Low voltage at the output of the sensor may be due to contamination or oxidation of the contacts in the circuit connections. Always check the condition of all contacts in the oxygen sensor circuit first.

- b) Outside air intake - The sensor is designed in such a way that outside air must enter its internal cavity. Whenever removing and installing or replacing a sensor, make sure that the air passages of the sensor are not clogged.

- V) Ensuring operating temperature - The control unit does not receive signals from the sensor until it warms up to a temperature of 320°C. This factor must be taken into account when evaluating the performance of the sensor.

- G) Use of Unleaded Gasoline - Only unleaded gasoline must be used to operate the sensor. Make sure that the fuel in the car's tank is correct.

6. In addition to the above conditions, the following precautions must be observed when servicing the sensor:

- A) The oxygen sensor has a flexible wire with a connector that is not disconnected from the sensor. Damage to the wire or connector may adversely affect sensor performance.

- b) Grease and dirt must not get on the connector and the working surface of the sensor.

- V) Do not use any solvents to clean the oxygen sensor.

- G) Handle the sensor carefully - do not drop it or subject it to shock.

- d) The sensor's silicone boot must be installed correctly to prevent it from melting and to ensure proper sensor operation.

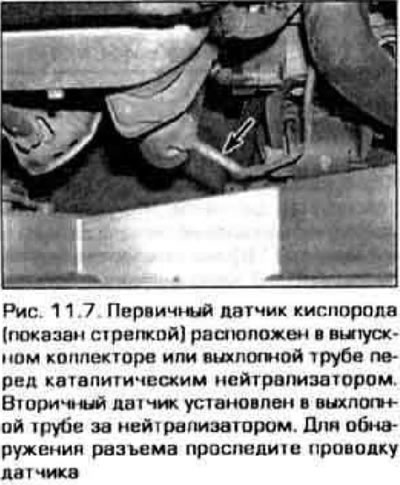

7. Locate the oxygen sensor electrical connector (fig 11.7) and, without connecting it, connect the voltmeter with long thin probes from the outside of the connector to the signal contact and to the ground contact. Apply the parking brake and place the shift lever in the "neutral" (Manual Transmission) or "parking" (Automatic transmission). Raise the front of the car and place it on jack stands.

8. Check the sensor signal under operating conditions. To do this, start the engine and watch the voltmeter reading as the engine warms up.

Attention! Be careful not to burn yourself on the heated elements of the exhaust system.

Note. Secondary oxygen sensors respond to a rich or lean mixture to a much lesser extent than the primary, since the catalytic converter converts CO, HC and NOx molecules into CO2, and H2 O with using excess oxygen.

9. When the engine is cold, the oxygen sensor outputs a constant voltage at the level of, for example, 0.1-0.2 V. The control system works without feedback. After about two minutes, when the sensor warms up and reaches operating temperature. the voltage at its output will begin to rise from 0.1 to 0.9 V (turn on feedback mode). If the sensor does not enter feedback mode or if it takes too long. Replace sensor.

10. Also check the sensor heater Disconnect the wiring from the sensor and connect a voltmeter to the heater contacts (check the connector pins according to the electrical diagrams at the end of chapter 12). The resistance of the heater should be in the range of 10-40 ohms.

11. Check the power supply to the heater (Specify the contacts according to the electrical diagrams). With the ignition on and the engine off, battery voltage must be supplied to the heater. If there is no voltage, check the circuits of the main relay, BEU and sensor.

12. If during the checks any deviations of the sensor parameters from those specified are revealed, replace the sensor.

Replacement

13. Since the sensor is installed in the exhaust system, which contracts when cooled, it may be that the sensor cannot be removed from a cold engine. To avoid overstressing the sensor, start the engine and warm it up for one to two minutes, then shut it off. Be careful not to burn yourself on hot parts of the exhaust system.

14. To access the sensor on some models, it may be necessary to raise the front of the vehicle and support it on stands.

15. From connect from the gauge an electric socket.

16. Carefully unscrew the sensor from the exhaust manifold (primary) or from the exhaust (secondary) (pic. 11.16).

17. When installing the sensor, it is recommended to use a compound that prevents the threaded connections from sticking. The new sensor is already coated with this composition. However, when reusing an old sensor, an anti-tack compound must be applied to the threads of the sensor.

18. Screw in the sensor and tighten it securely.

19. Connect the connector at the end of the sensor wires to the engine wiring harness.

20. Lower the vehicle, test drive it and make sure no trouble codes appear.