Air conditioning system

1. In order to make sure that the air conditioning system is fully operational, the following checks should usually be performed:

- A) Inspect and check the condition of the compressor drive belt. If it is worn or has signs of decomposition. replace it.

- b) Check and, if necessary, adjust the belt tension (see chapter V.

- V) Inspect the system hoses for cracks, bulges, hardening and decomposition of the rubber Look for possible signs of oiling of the hoses and their connections Replace the hose at the slightest suspicion of a malfunction.

- G) Inspect the condenser core for debris and insects. If necessary, blow out the core with compressed air.

- d) Make sure the system is fully charged with refrigerant.

2. At least once a month, turn on the system and let it run for at least 10 minutes, including in winter.

3. Serious repair of the air conditioning system requires special equipment and experience. For this reason, such works, as a rule, are beyond the power of a motorist, but they are not considered here either. However, some simple maintenance procedures and the replacement of some parts of the system may well be within his power and can be performed without special equipment and special skills.

4. The most common cause of air conditioner not working efficiently is refrigerant leakage. If the system is experiencing a decrease in cooling capacity during operation, the following quick checks will help to determine for sure that the reason lies in the decrease in the level of refrigerant.

Examination

5. Warm up the engine to normal operating temperature.

6. Set the air temperature control to the coldest position and turn on the fan at the highest speed. Open doors to prevent recirculation of chilled air.

7. After the system has reached a steady temperature, feel the two tubes attached to the evaporator on the engine baffle.

8. One of them. the smaller diameter one that connects the condenser to the evaporator should be cold, and the second thicker tube coming out of the evaporator and going to the compressor should be slightly cool (+12...+16°C). If the outlet tube of the evaporator is significantly warmer than the inlet, then the system needs to be recharged. Measure the temperature of the air leaving the central ventilation grill (pic. 14.8) - it should be 20-25 degrees below the outside temperature, up to about +5°C. If the air does not cool as much, then most likely the system needs to be refueled. Further checking of the air conditioning system is beyond the capabilities of the motorist and should be entrusted to specialists.

Topping up the system with refrigerant

Keep in mind: Up until 1993, air conditioning systems were charged with R-12 refrigerant. Since 1994, the refrigerant has been replaced with the more environmentally friendly R-134a. These refrigerants are not compatible, just as the oils used with them in the air conditioning system are not compatible. The systems have different piping connections, so it is not possible to install a part from a new system to an old one and vice versa. When topping up the system or changing the refrigerant, make sure the correct type of refrigerant is being used.

Note. Models charged with R-12 refrigerant should only be serviced at specialized stations.

Release models since 1994 (with R-134a refrigerant)

9. Purchase a refill kit (pic. 14.9,a). The kit includes a 400 gram can of R-134a refrigerant. a faucet and a piece of hose that connects between the faucet and the valve on the low pressure side of the system. System low pressure valve (filling valve) located in the piping leading to the engine bulkhead (pic. 14.9.6). Since one can of refrigerant may not be enough to fully recharge the system, it is better to purchase an additional can just in case.

|  |

Caution: Never add more than two cans of refrigerant to the air conditioning system - this is the capacity of the entire system.

10. Connect the supplied charger to the system, strictly following the manufacturer's instructions. Unscrew the valve of the charger valve to raise the needle and screw the device to the refrigerant can (check if the o-ring inside the charger adapter is in place).

Attention! Wear a face shield when working with pressurized refrigerant.

11. Remove the protective cap from the system charge valve and connect the charge kit hose connector to it.

Attention! DO NOT CONNECT the charging hose to the high pressure side of the system! The hose connector in the kit is designed to connect to the low pressure side only.

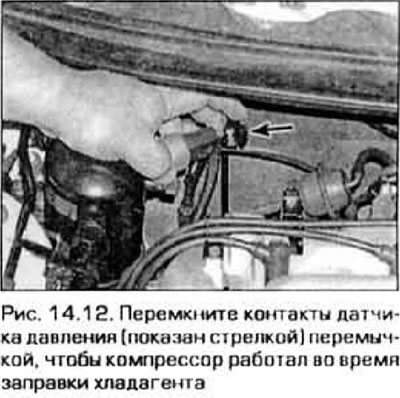

12. Warm up the engine to normal operating temperature and turn on the air conditioner. Make sure that the charger hose does not come into contact with rotating parts of the engine. If the A/C system is heavily discharged, the pressure sensor on the receiver/dryer may not turn on the compressor, so disconnect the sensor connector and bridge the two connector pins with a jumper wire (pic. 14.12).

13. Screw in the charger valve until the valve needle pierces the refrigerant can, then turn the valve back to open the refrigerant passage. You should hear the sound of gas entering the system. Charge the system until both evaporator tubes - inlet and outlet - are about the same temperature by touch. Add refrigerant in batches and wait between charges to stabilize.

Note. During the charging process, the refrigerant can will cool down and may freeze to the point that the refrigerant supply to the system will stop. To prevent this from happening, wrap the jar with a towel soaked in hot water.

14. You can measure the temperature of the air leaving the ventilation grille into the passenger compartment with a thermometer (see fig. 14.8). If the system is charged and working properly, the temperature should drop to about 5°C.

15. After emptying the can, turn the filling valve into a closed valve and disconnect the hose from the low pressure valve of the system. Put the protective cap on the valve.

16. Unscrew the filling device from the can and store it for the next filling.

Heating system

17. If the air coming out of the ventilation grilles is not warm enough, this may be the result of the following malfunctions.

- A) The thermostat is stuck open and the engine coolant cannot heat up enough to heat the heater core. Replace thermostat (paragraph 3).

- b) The heater hose is clogged and does not allow the necessary circulation of fluid in the heater radiator. Feel both heater hoses on the engine bulkhead - they should be hot. If one of the hoses remains cold, either the hose or the heater core is blocked or the heater control valve is closed. Disconnect the hoses from the heater core and flush the radiator with clean water from the hose. If the radiator is not clogged and there is no fluid circulation, remove both heater hoses and flush them with water

- V) If the heater core is clogged and flushing fails to remove the clog, replace it.

18. If the heater fan speed does not match the switch setting, the cause may be a faulty fuse, power supply or relay circuit of the motor, speed switch or resistor (see paragraph 10).

19. If no air comes out of the grilles, then:

- A) Turn the ignition on and turn on the fan, put your ear to the ventilation grill and listen to see if the fan is running.

- b) If the fan does not work, although the speed switch and resistor are good, then the fan motor may be faulty (see paragraphs 10 and 11).

20. If the carpet under the heater core has become damp, or steam is escaping through the grates, this may indicate a leak in the heater core. Take it off (see paragraph 13) and replace with a new one (heater radiators, as a rule, are not repaired).

21. Check the drain hose from the heater/evaporator unit on the right side of the engine bulkhead and make sure it is. that it is not blocked (pic. 14.21). If wet steam is coming out of the system ducts, this hose may be clogged with leaves or road grime.

Smells from the air conditioner

22. The unpleasant smell that occurs in the cabin during the operation of the air conditioner is caused by a mold fungus that breeds on the core of the evaporator. The humid warm environment in this place is a favorable habitat for them.

23. On most models, the evaporator is difficult to reach. Some of the workshops that have dealt with this problem use laborious and expensive techniques that include opening the evaporator body, rinsing and treating the core with strong disinfectants. It is possible to perform such disinfection in a garage, but this will require chemical reagents that are stronger than conventional deodorants or disinfectants.

24. Auto supply stores may have aerosol cans for this job, but be aware that effective products are usually expensive. If such an aerosol was obtained, then proceed as follows. Turn on the A/C system, turn on the fan at high speed and let the system run in RECIRC mode (recycling) within approximately 10 minutes. Dry the system elements by setting the maximum air temperature. Then turn off the compressor by disconnecting its electrical connector (see paragraph 16).

25. Usually the spray can is supplied with long hoses with a sprayer. Remove the heater fan resistor (see paragraph 10), aim the atomizer at the left side of the hole, in the area of the evaporator grille (pic. 14.25) and treat the evaporator according to the manufacturer's instructions. Try to cover its entire surface, for which direct the jet down-up-right-left. Follow manufacturer's recommendations for spray duration and reapplication intervals.

26. After treating the evaporator, to prevent mold from reappearing, keep the evaporator drain hose clean (see fig. 14.21). After a long operation of the air conditioner, turn on the defrost mode for a short time (DEF), to dry the evaporator.