Examination

1. When checking, the engine should be raised a lot to crush the load from its supports.

2. Raise the vehicle and place it on jack stands. Place a hydraulic jack under the engine, placing a wooden block on its head so as not to damage the sump. Carefully jack up the engine just enough to relieve the mounts.

Attention! DO NOT work under the engine if it is only on a jack.

3. Inspect the engine mounts. First of all, pay attention to the rubber blocks - are there any cracks in them, delamination from the metal base, whether the rubber has hardened. The destruction of the rubber block usually starts from the central hole.

4. Check for play in the supports. To do this, insert a strong screwdriver or pry bar into the support and shake the engine relative to the support. If play is evident, lower the engine and tighten the support hardware.

5. To reduce the likelihood of rubber decomposition, the supports should be coated with protective compounds.

6. Disconnect the negative cable from the battery, set the parking brake, put blocks under the wheels, raise the front of the car and support it on props (if it hasn't already been done).

Warning! If your car has an anti-theft audio system, make sure you have the unlock code before disconnecting the battery.

Replacement

Right support (passenger side)

7. The support supporting the power block on the side of the drive of the gas distribution mechanism is attached to the chassis of their block. To replace the support, unload it by lifting the engine from above using the lifting eye or support the engine from below with a hydraulic jack. Place a block of wood on top of the jack to secure the pallet.

8. Unscrew the mount pinch bolt, then the mount-to-chassis bolts and pull out the rubber block (pic. 16.8).

9. Installation of the support is carried out in reverse order.

Note. Before final tightening of the fasteners, lower the power block and remove the supporting jack. If several supports have been replaced, see below for final tightening procedures.

Front support

10. The front support is located between the engine and the radiator (pic. 16.10).

11. To remove the front support, follow the steps indicated in paragraphs. 7-9.

12. Installation is carried out in reverse order.

Note. Before final tightening of the fasteners, lower the power block and remove the supporting jack. If several supports have been replaced, see below for final tightening procedures.

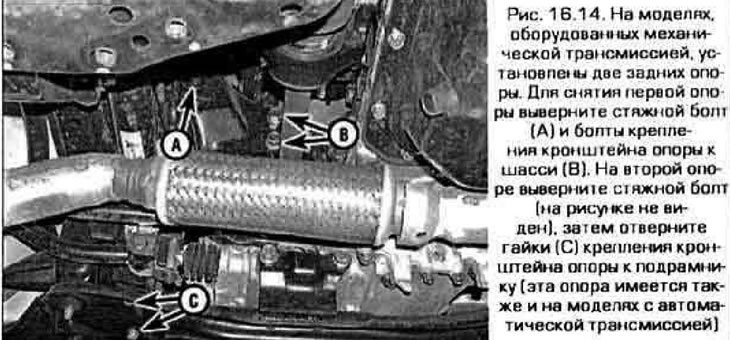

Rear support

13. If you do not remove the intake manifold, access to this support will be difficult and only possible from below. Loosen the pinch bolt and lift the power block to take the load off the support.

14. Turn away nuts of fastening of a support to a stretcher. completely unscrew and pull out the tie bolt and lift the power unit so that it is possible to pull out the support (pic. 16.14).

15. Installation is carried out in reverse order.

Note. Before final tightening of the fasteners, lower the power block and remove the supporting jack. If several supports have been replaced, see below for final tightening procedures.

Left support (from the driver's side)

Upper support

16. The support on the driver's side is attached from above to the transmission and to the chassis (pic. 16.16).

17. Support the power block, turn out the coupling bolt, bolt and nut securing the support to the transmission and remove the support.

19. Install the support in reverse order.

Note. Before final tightening of the fasteners, lower the power block and remove the supporting jack. If several supports have been replaced, see below for final tightening procedures.

Bottom support

19. The lower support connects the transmission to the subframe (pic. 16.19).

20. Support the power block. Remove the two bolts securing the support to the transmission and the two nuts securing the subframe.

Final tightening of all supports

21. When all supports are finally tightened, the vehicle must be level and the weight of the power unit must be on the supports. Fill threaded connections with anti-self-loosening compound. Screw in all fasteners of all supports, first by hand, then gradually tighten it until the required torque is reached.