Sequential fuel injection

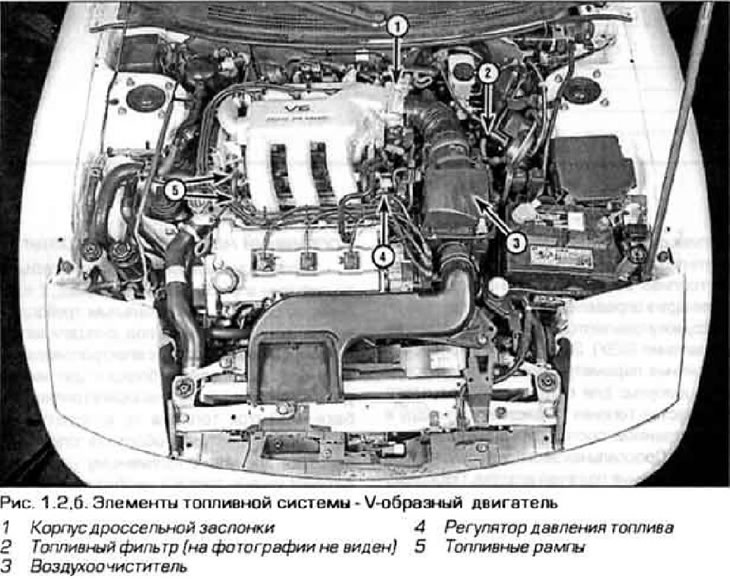

The sequential fuel injection system generates pulses of a certain duration for sequential injection of fuel into the intake channels of each cylinder at a certain point in time. Nozzles are controlled by an electronic control unit (BEU). This block controls various engine parameters and generates an impulse to supply the required amount of fuel to each cylinder in a certain sequence (pic. 1.2, a, b). The throttle valve serves only to control the air supply. Since each cylinder is equipped with an injector mounted next to the intake riveter, the air/fuel mixture is managed very efficiently.

Fuel pump and lines

Fuel circulates from the fuel tank to the fuel injection system and back to the fuel tank through two steel pipes located under the bottom of the vehicle. The electrically driven fuel pump is mounted in one unit with the fuel level sensor installed in the fuel tank. Excess fuel flows back to the fuel tank through the return line. The fuel tank must be removed to access the fuel pump and fuel gauge.

All models have a main fuel system relay located on the fuse box in the engine compartment. The main relay is controlled by several circuits. The relay is turned on by the BEU, which closes its coil circuit to ground when the ignition key is in the START, RUN, or ON positions.

Exhaust system

The lawn exhaust system on a 4-cylinder engine consists of an exhaust manifold in which an oxygen sensor is installed, a catalytic converter, an exhaust pipe and two silencers. The non-V-shaped engine has two exhaust manifolds, a Y-shaped exhaust pipe, a catalytic converter and two silencers.

The catalytic converter installed in the exhaust system is a device for reducing the toxicity of exhaust gases. The neutralizer converts the three main toxic constituents into harmless substances: carbon monoxide (carbon monoxide), unburned hydrocarbons and oxides of nitrogen. For more information about the catalytic converter, see chapter 6.