Removing

1. Disconnect the wires from the battery (first negative, then positive).

Caution: If your vehicle's audio system has an anti-theft protection, make sure you know the unlock code before disconnecting the battery.

2. Remove the inlet duct and air cleaner (see chapter 4).

3. Remove the starter (see chapter 5).

4. Disconnect from transmission an electric socket of the gauge of provision of the selector and the tire of grounding. Unhook the wiring harnesses that are attached to the trans mission.

5. Disconnect the wiring harness connector on the side of the transmission. The connector is rectangular on 4EAT and GF4A-EL transmissions, oval on CD4E and LA4A-EL transmissions.

6. Disconnect the selector cable on the transmission (see paragraph 4).

7. Disconnect the electrical connector from the vehicle speed sensor.

8. Disconnect the cooling hoses from the transmission.

9. Raise the car and place it on supports. Mount the engine on a beam mounted on top of the engine compartment (pic. 8.9). If there is no such device, then the engine can be pulled up with a hoist. The engine must be securely supported while the transmission is removed from the vehicle.

10. Turn out the top bolts of fastening of transmission to the engine (pic. 8.10).

11. Remove the fuel filter bracket together with the filter and move them to the side.

12. Remove the left engine mount (see chapter 2A or 2B).

13. Remove the front wheels.

14. Drain the fluid from the transmission (see chapter 1).

15. On a 4-cylinder engine, remove the intake manifold support bracket.

16. Disconnect steering drafts from rotary fists.

17. Release the intermediate shaft support and disconnect the shaft from the transmission (see chapter 8).

Note. On a V-engine, remove the bolts securing the exhaust pipe to the exhaust manifold and lower the exhaust system.

18. Pull the right drive shaft along with the intermediate shaft from the transmission. Disconnect the left drive shaft from the transmission (see chapter 8). Place a plastic bag over the inner shaft joint to protect it from dirt.

19. Insert into the transmission holes from which the shafts were removed, plugs or long thorium heads to keep the differential side gears in the installation position (see fig. 4.19, a and 4.19, b in chapter 7A). There are special branded inserts for this purpose, however, if homemade plugs or thorium heads are well fixed, then they can serve as a very suitable alternative. Note: If this is not done and the side gears move, the transmission will have to be disassembled.

20. Remove the lower mudguard Remove the six bolts securing the lower cross member and remove the cross member from the vehicle (pic. 8.20).

21. On a V-shaped engine, disconnect the electrical connectors from the left and right oxygen sensors (see chapter 6).

22. On engines with ABS, remove the wheel speed sensors and disconnect their wiring from the body parts.

23. Mark the position of the transmission support beam relative to the body to facilitate subsequent assembly. Remove the six bolts and two nuts securing the transmission support beam and remove the beam (pic. 8.23). When loosening the last bolt, support the beam so that it does not fall.

24. Turn away nuts of fastening of the hydrotransformer to a faceplate. Use the starter hole to access the nuts on models with CD4E/LA4A-EL transmissions, and on 4EAT/GF4A-EL models, remove the protective cover from the bottom of the transmission. Turn the engine crankshaft as needed to loosen the next nut (The torque converter is usually held in place with four nuts).

25. Place a jack under the gearbox (for this purpose, it is preferable to use a special jack). If you are using a mobile jack, place a block of wood between the jack and the transmission pan to protect the aluminum housing. Fix the gearbox on the jack with chains.

26. Remove the transmission support and support bracket. For more information on supports, see chapters 2A or 2B.

27. Turn away the remained bolts of fastening of transmission to the engine.

28. Make sure once again that all hoses and wires are disconnected from the transmission. Carefully move the transmission along with the jack away from the engine. Lower the transmission and pull it out from under the vehicle.

29. After disconnecting the transmission, inspect the torque converter, its seals and other transmission seals (transmission side cover seal, speed sensor seal, etc.) for wear and damage. If necessary, replace seal damage.

Installation

30. If the torque converter has been removed from the transmission, install it.

31. Install and secure the transmission on the jack cart with a chain, roll it under the car and lift it into the installation position. Carefully slide the transmission towards the engine, aligning the transmission dowel pins with the corresponding engine holes and the bolt holes in the faceplate and torque converter. Do not apply too much force when connecting the transmission to the engine. If the torque converter does not fit into place, re-angle the transmission and align it with the engine.

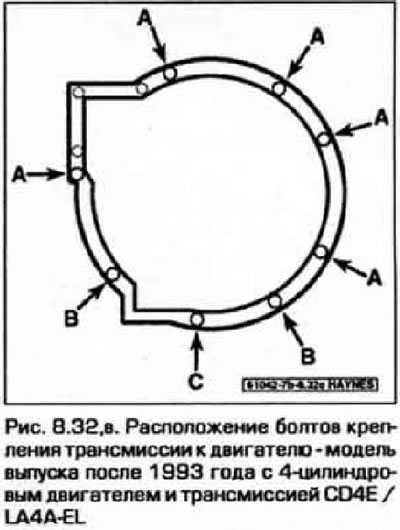

32. Screw in the bolts of the transmission to the engine (pic. 8.32, a-c).

- A) On a 1993 4-line engine model with a 4EAT/GF4A-EL transmission, tighten bolts B, C, D, E, then F to the torque specified in Technical Data at the beginning of the chapter.

- 6J On 1993 or later V-engine models with 4EAT/GF4A-EL transmission, torque bolts A.

- V) On post 1993 4-pin drive models and CD4E/LA4A-EL transaxles, torque bolts B and C.

|  |

33. Tighten bolts to an arm of a back support of the engine. See chapter 2A or 2B.

34. Establish not transmission the bottom left support. See chapter 2A or 2B.

35. Attach the selector cable to the transmission lever (see paragraph 3).

36. Install the transmission support beam. aligning it with the previously marked marks m. Tighten the beam fasteners to the required torque (see fig. 8.23).

37. Install the crossbar (see fig. 8.20) and tighten its bolts to the required torque.

38. Screw in the remaining bolts of the transmission to the engine (see fig. 8.32, a-c).

- A) On a 1993 4-cylinder model with a 4EAT/GF4A-EL transmission, tighten bolts A to the torque specified in Technical Data at the beginning of the chapter.

- b) On a 1993 or later V-engine model with a 4EAT/GF4A-EL transmission, torque tighten bolts B.

- V) On a 1993 Ambassador 4-cylinder model with a CD4E/LA4A-EL transmission, torque bolts A.

39. Remove plugs from transmission outlets.

40. Install intermediate and drive shafts (see chapter 8).

41. Connect the tie rods to the steering knuckles (see chapter 10).

42. Reinstall the lower mudguard, install the front wheels and lower the vehicle to the ground.

43. Screw in the bolts of the front engine mount bracket (see chapter 2A or 2B).

44. Perform the rest of the installation in the reverse order of removal.

45. Fill the transmission with the correct type of fluid (see chapter 1).

46. Take the car for a test drive, make sure that all car systems work properly. Check for leaks.

47. Loosen and retighten the power block supports.

48. Adjust wheel alignment.