Removing

1. Loosen the right front wheel nuts, raise the front of the vehicle and place it on stands. Remove the right wheel.

2. Drain the fluid from the transmission (see chapter 1).

3. Disconnect the hinge of the right lever from a rotary fist (see chapter 10).

4. Pull the inner joint of the input shaft from the intermediate shaft. Take the drive shaft to the side and secure it with wire (otherwise, the external hinge of the drive shaft may break).

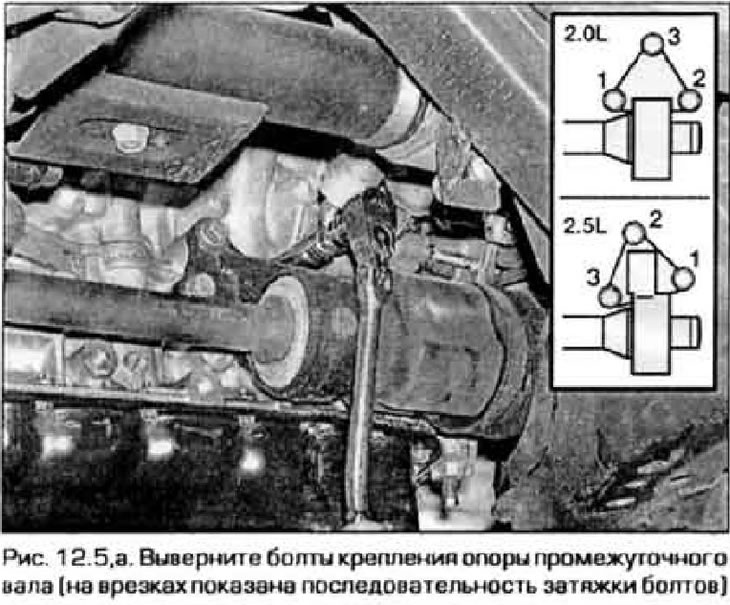

5. Turn out three bolts of fastening of a support of an intermediate shaft to the engine (pic. 12.5,a) and carefully remove the shaft from the gearbox (pic. 12.5, b) Be careful not to damage the seal.

6. Caution: If you also remove the left drive bike. insert plugs to fix the differential gears (see fig. 4.19, a, b in chapter 7A). There are special plugs for this chain, however, you can use suitable homemade fixtures.

7. Check up smoothness of rotation of the bearing of an intermediate shaft. To do this, while holding the shaft, rotate the bearing. If the bearing rotates noisily, contact a service station to replace the bearing.

Installation

8. Remove the plug from the differential gear (if it was installed).

9. Lubricate the differential seal lip with a small amount of universal grease. Carefully insert the intermediate drive into the differential gear, then insert the support mounting bolts. Tighten the bolts to the required torque, working in the sequence shown in fig. 12.5.a.

10. Install a new snap ring on the intermediate shaft (see fig. 11.10, a, 6) and insert the inner horse of the input shaft into the intermediate shaft.

11. Connect the ball joint to the steering knuckle and tighten the coupling bolt to the required torque (see technical data at the beginning of chapter 10).

12. Mount the wheel, tighten the wheel nuts Lower the vehicle and sharpen the wheel nuts to the required torque (see technical data at the beginning of chapter 1).

13. Fill the fluid in the transmission (see chapter 1).