Removing

1. Relieve pressure in the fuel system (see chapter 4). Disconnect the negative cable from the battery.

Warning; If your vehicle's audio system is equipped with an anti-theft system, make sure you know the unlock code before disconnecting the battery.

2. Remove the inlet duct and air cleaner (see chapter 4).

3. Remove the starter (see chapter 5).

4. Disconnect all electrical connectors and ground rails from the transmission. Disconnect the wiring harness from the transmission.

5. Engage the gearbox in reverse.

6. Disconnect the shift rod and jet link from the transmission (see paragraph 2). It is not necessary to disconnect the linkages from the shift lever housing. Move the rods to the side and tie them from below to the body with a piece of wire.

7. Disconnect the vehicle speed sensor connector (see chapter 6).

8. Remove the clutch slave cylinder from the transmission and tie it up somewhere to the side.

Be careful: Do not kink the clutch actuator pipe and DO NOT depress the clutch pedal while the slave cylinder is removed.

9. Raise the vehicle and place it on jack stands. Mount the engine on the cross beam (see fig. 8.9 in chapter 7B). If there is no such device, tighten the engine with a hoist.

10. Turn out the top bolts of fastening of transmission to the engine.

11. Remove the fuel filter (see chapter 1).

12. Remove the left engine mount (see chapter 2A).

13. Remove the front wheels of the car.

14. Drain the transmission oil (see chapter 1).

15. On a model with a 4-cylinder engine, remove the intake manifold support bracket (pic. 4.15).

16. Remove the exhaust system.

17. Disconnect the steering rods from the steering knuckles (see chapter 10).

18. Remove drive shafts and intermediate shaft (see chapter 8).

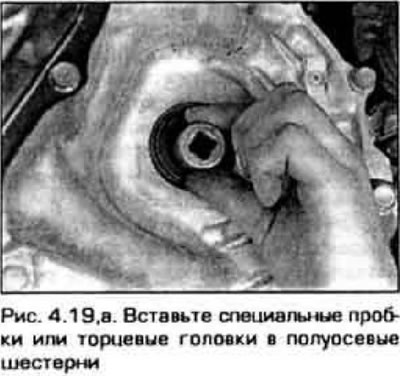

19. Lock the side gears of the differential from mixing. There are special plugs for this, but in the absence of such, you can get by with socket heads of a suitable size (pic. 4.19,a,6) or wooden plugs. Take into account. If you do not fix the side gears and they move, the transmission will have to be disassembled.

20. Remove mud flaps. Unscrew the six bolts securing the cross member to the floor of the transmission and remove the cross member (pic. 4.20, see also fig. 1.1).

21. On vehicles with ABS, release the wheel speed sensor wiring from both sides of the vehicle.

22. Mark position of a basic beam of transmission concerning the bottom of a body.

23. Turn away bolts and nuts of fastening of a basic beam. Photos of the support beam are given in chapter 7B.

24. Remove the shield that blocks access to the clutch (pic. 4.24).

25. Support the transmission from below with a trolley jack Secure the transmission securely on the platform of the trolley with a chain.

26. Remove the transmission standoff and support bracket. For more information about the power block supports, refer to chapters 2A or 2B.

27. Remove the transmission support bolts above the intermediate shaft and the bolt next to the clutch slave cylinder (pic. 4.27). Turn out two bolts of an arm of a back support of the engine.

28. Inspect the transmission again to see if all the hoses and wires are disconnected and if anything will prevent its removal. Separate the transmission from the engine. Once the input shaft is free, lower the transmission jack and roll the transmission out from under the vehicle.

29. After removing the transmission, all clutch parts become available for inspection. It is recommended to make it a rule to change clutch parts (first of all, the driven disk and the release bearing, see chapter 8) if the transmission is removed for some reason.

Installation

30. Install the clutch (if it was taken).

31. Fix the transmission on the trolley-jack, roll it to the installation site and lift it to the installation position. Slide the transmission towards the engine, aligning the dowel pins with the appropriate holes and the input shaft with the clutch disc hub. Do not apply much force to the transmission - if the input shaft does not fit freely into the disc hub, change the angle of the transmission relative to the engine or rotate the transmission input shaft so that its splines are aligned with the splines of the friction disc.

32. Install the lower transmission-to-engine mounting bolts and the rear engine support bracket bolts. Installation of supports is described in detail in chapter 2A.

33. Install the lower left support on the transmission (tightening torques are given in chapter 2A).

34. Connect to transmission draft of a gear change and reactive draft.

35. Install a support beam under the transmission, aligning the previously applied marks and tighten the bolts of its fastening to the required torque (see fig. 8.23a chapter 7B). Attach the power steering hydraulic line.

36. Remove the plugs from the side gears of the transmission.

37. Install intermediate shaft drive shafts (see chapter 8).

38. Install the cross member under the transmission and tighten its bolts to the required torque.

39. Connect the tie rods to the steering knuckles (see chapter 10).

40. Install mudguard and front wheels. Lower the vehicle to the ground.

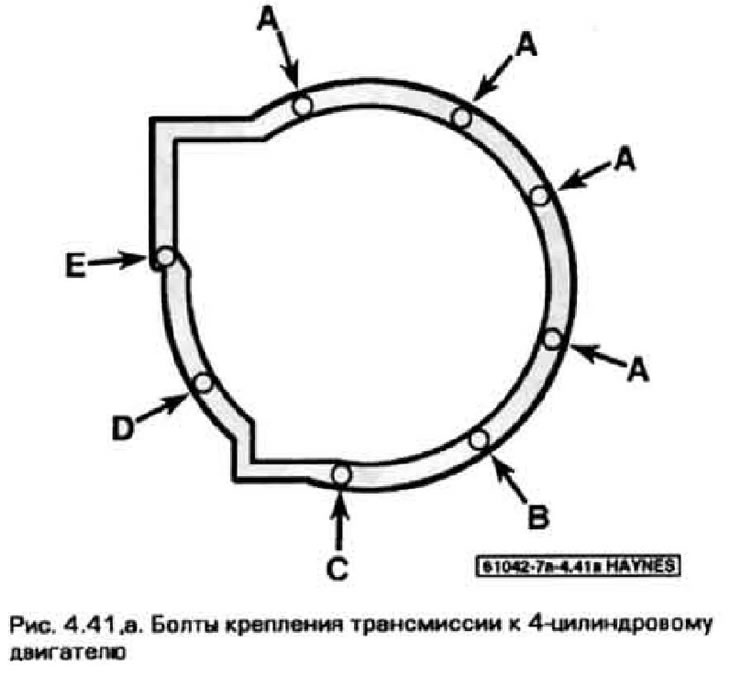

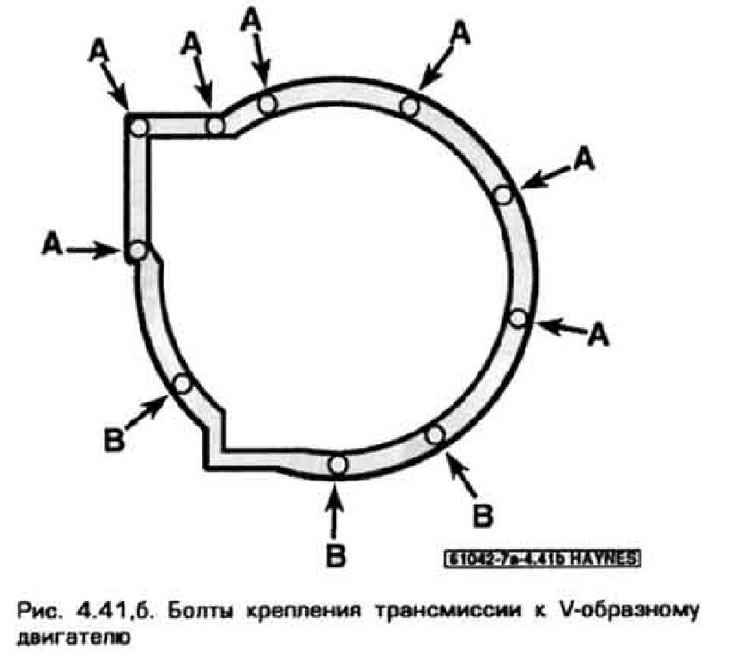

41. Screw in the remaining transmission mounting bolts (pic. 4.41, a, b) and tighten them to the required torque.

42. Screw in the bolts of the front engine mount (see chapter 2A).

43. The remaining parts are installed in the reverse order of their removal.

44. Fill the transmission with oil (see chapter 1).

45. Check the operation of the clutch and release the air from its hydraulic drive.

46. Take a test drive to check the operation of all systems. Make sure there are no leaks.

47. If vibration of the power unit is observed, loosen and re-tighten the support bolts to the required torque.

48. Adjust wheel alignment.