Disassembly

Remove the clamps securing the protective covers of the steering rods, and slide the covers along the rods.

Turn the rack gear to the stop of the restrictive ring in the crankcase in one direction and clamp the steering gear in a vice with soft lining.

Bend back tabs of a lock washer of an internal hinge of steering draft, turn out draft from a lath and remove draft.

Turn the rack gear to the stop of the restrictive ring in the crankcase in the opposite direction and remove the other steering rod in the same way.

Note: Before removing, put marks on the rods to put them in their original places when reassembling.

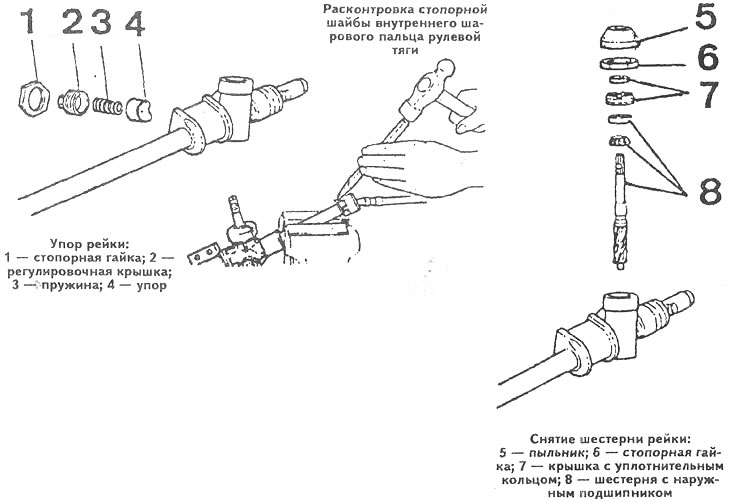

Remove lock nut 1 in series (see picture), adjusting cover 2, spring 3 and rail stop 4.

Remove boot 5 (see picture) from the rack gear, unscrew the lock nut 6, remove the gear cover assembly with the sealing ring 7, remove the gear 8 from the crankcase together with the outer ball bearing.

Remove the rack from the steering gear housing in the direction opposite to the rack support sleeve.

Place the steering gear housing on the side of the gear seat in a tank of water heated to about 80°C, and remove the inner gear bearing by tapping the housing with a mallet.

Remove both crankcase mounting brackets with rubber bushings.

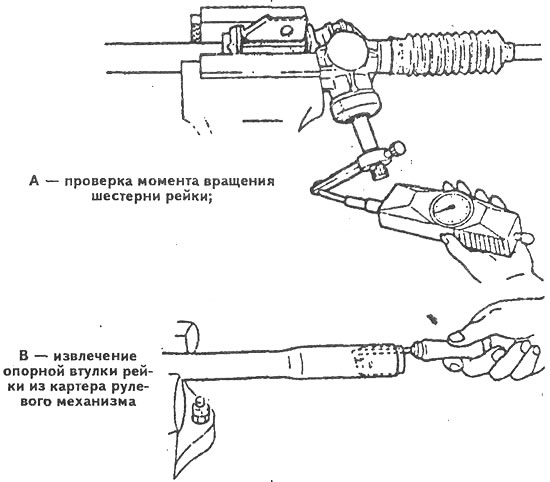

Remove the rack support sleeve from the side opposite the bearing seat with a hook, after first pressing out the three locking tabs on the crankcase tube (see picture).

Checking the technical condition

Before assembling the steering gear, check:

- the condition of the protective covers and rubber bushings of the steering gear mounting brackets;

- the degree of wear, the absence of scoring, cracks on the rack and drive gear;

- asymmetric wear of the working surface of the rail stop;

- play in the internal ball joints of the steering rods;

- play in the bearings of the drive gear and play of the rack support sleeve.

Note: In addition to the obligatory replacement of defective parts, the gear cover oil seal, drive gear outer and inner bearings, and rack support bushing should be replaced each time the steering mechanism is disassembled.

Assembly

Lubricate contacting or rubbing parts with lithium grease before installation.

Lubricate the gear inner bearing liberally and press it into the crankcase seat with the drive gear.

Install the rack support bushing into the steering gear case so that its profile matches the profile of the rack after it is installed, and that the three locking tabs fit into the grooves.

Establish two brackets of fastening of the steering mechanism with rubber plugs.

Liberally lubricate the rack teeth with lithium grease, carefully insert the rack into the steering gear housing from the side opposite the support sleeve.

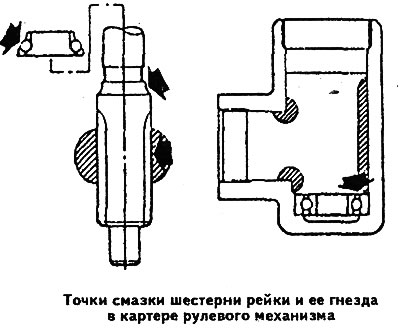

Lubricate the pinion with the outer bearing pressed onto it and the bearing housing at the points indicated in the figure, using approximately 30 g of grease.

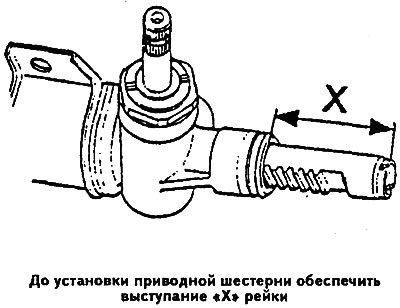

Slide the rack out of the steering box until it protrudes 66.7mm (size «X» see picture), and install the drive gear into the crankcase.

Reinstall the drive gear cover with a new oil seal and tighten the cover with a torque of 7.0-9.0 kgf·m.

Screw and tighten the lock nut of the drive gear cover with a torque of 8.0-10.0 kgf·m, then put the boot in place.

Lubricate the rail stop and install it in the crankcase until it stops against the rail.

Install the spring, screw on the cover and adjust the rail stop in the following order:

- tighten the stop cover with a force of 10 kgf·m and loosen it;

- tighten the cover with a force of 3 kgf·m and unscrew it at an angle of 0-15°;

- tighten the lock nut of the cover with a force of 4.0-6.0 kgf·m;

- attach a dynamometer to the splined end of the drive gear of the rack and measure the torque of the gear, which should be in the range of 1.0-1.4 N·m;

- if the obtained value does not fit within the specified limits, loosen the lock nut and change the position of the stop adjusting cover until the required gear torque is obtained;

- after adjustment, tighten the lock nut of the adjusting cover of the rail stop with a torque of 4.0-6.0 kgf·m.

Turn the rack gear to the stop of the restrictive ring in the crankcase in one direction and clamp the protruding part of the rack in a vice with soft pads.

Install a new lock washer of the inner ball joint of the steering rod, install the rod and tighten its inner joint with a force of 8.0-10.0 kgf·m.

Bend the lugs of the linkage ball joint lock washer.

Turn the rack gear until the restrictive ring stops in the crankcase in the opposite direction and install the other steering rod in the same way.

Install the protective covers of the rods and secure them with clamps.