Crankshaft

The crankshaft is cast iron, five-bearing with five counterweights. Main journals diameter, mm:

- nominal: 49.940-49.956;

- wear limit: 0.05.

Diameter of connecting rod journals, mm:

- nominal: 39.940-39.956;

- wear limit: 0.05.

It is possible to regrind the crankshaft journals during repairs with a diameter reduction of 0.25; 0.50 and 0.75 mm. Axial clearance of the crankshaft, mm:

- nominal: 0.10-0.15;

- maximum allowable wear clearance: 0.30.

Pistons

Pistons are cast from aluminum alloy. The piston pin is pressed into the upper head of the connecting rod and rotates freely in the piston bosses. Three rings are installed on each piston: two compression rings and an oil scraper.

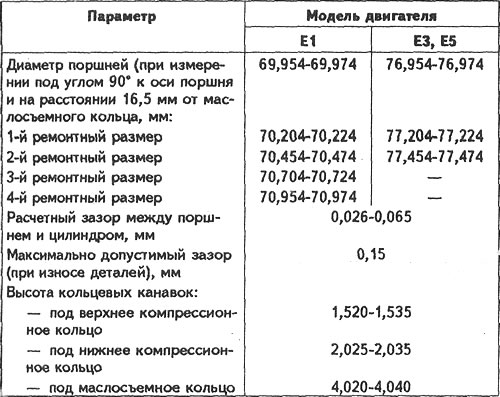

Piston characteristics

Piston rings

Thickness of compression rings, mm:

- upper: 1.47-1.49;

- lower: 1.97-1.99.

Gap between ring and groove, mm:

- top compression ring: 0.03-0.065;

- lower compression ring: 0.035-0.065.

Maximum allowable clearance (when worn), mm: 0.15.

Gap in the lock, mm:

- upper compression ring: 0.15-0.30;

- lower compression ring: 0.15-0.30;

- oil scraper ring: 0.30-0.90.

Maximum allowable clearance (when worn), mm: 1.0.

Piston pins

Diameter, mm: 19.976-19.988.

Gap between pin and piston, mm: 0-0.024.

The force of pressing the piston pin into the upper head of the connecting rod, tf: 0.5-1.5.

Connecting rods

Connecting rod steel, forged, I-section with a cover of the lower head of direct section.

The distance between the axes of the holes of the connecting rod heads, mm:

- E1 and E3: 141.15-142.25;

- E5: 135.95-136.05.

The maximum allowable buckling of the connecting rod,%: 0.04.

Hole diameter, mm:

- connecting rod head: 19.948-19.961;

- bottom end of connecting rod: 43.000-43.016.

The width of the lower head of the connecting rod, mm: 21.838-21.889.

Gap between connecting rod and piston, mm:

- nominal: 0.110-0.262;

- maximum allowable (when worn): 0,30.