2. Mark the position of the wheel disc in relation to the hub so that the balanced wheel can be returned to its original position.

3. Loosen the wheel nuts of the car standing on the ground.

4. Raise the front of the car.

5. Remove the wheel.

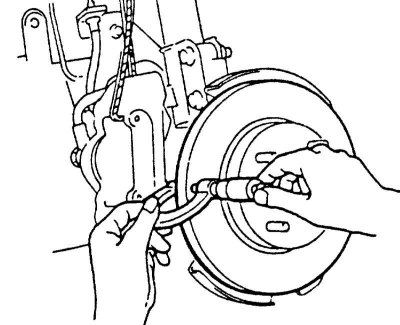

6. Vehicles since 10/89, except models "station wagon": Screw on the 2 wheel nuts so that the brake disc is correctly centered.

7. Measure the thickness of the brake disc. In workshops, a special gauge or micrometer is used for this, because due to wear, an edge forms on the brake disc. The thickness of the disc can also be measured with a standard caliper, but a spacer of known thickness should be placed on each side of the disc. To determine the exact thickness of the disc, subtract the total thickness of the gaskets from the obtained value.

Attention! The measurement is made at several points on the disk.

8. If the wear limit is reached, the brake disc must be replaced. Wear limit see Section Brake system technical data

9. If there are large cracks and grooves deeper than 0.5 mm, the brake disc should be replaced.

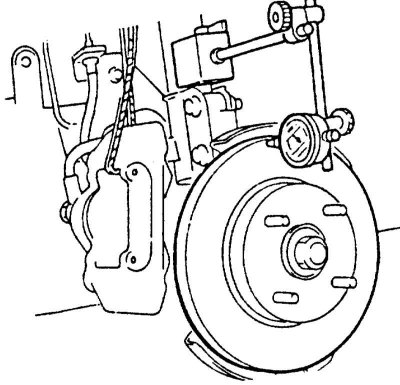

10. If there is a dial indicator, measure the lateral runout of the brake disc in the installed state. Set the indicator to the outer edge. Required value: maximum lateral runout 0.1 mm. Excessive lateral runout can be caused by a broken wheel bearing, have it checked by a workshop.

11. If necessary, unscrew the wheel nuts.

12. Screw the wheel, taking into account the mark on the hub. Lower the vehicle and tighten the wheel nuts crosswise with force 100 Nm.