Removing

1. Mark the position of the wheel disc relative to the hub so that the balanced wheel can be returned to its original position.

2. Loosen the wheel nuts of the car on the ground.

3. Raise the front of the car.

4. Remove the wheel.

Attention! Swapping the pads of the right and left wheels is unacceptable. Swapping can lead to uneven braking action. It is obligatory to replace all pads of one axle at the same time, even if only one pad has reached the wear limit. If the pads are to be installed again, they should be marked before being removed.

5. Cars since 10/89, except models "station wagon": Slightly screw on the 2 wheel nuts to secure the brake disc.

6. Pull the brake caliper outward by hand and press the piston in this way.

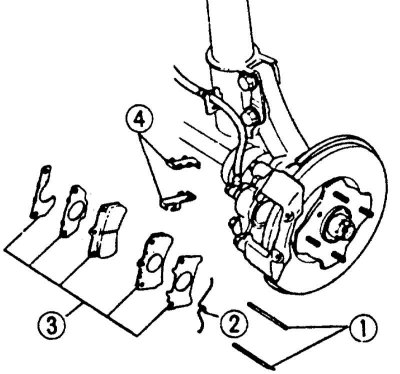

Cars up to 9/89, issue. And "station wagon"

1. Remove individual elements in numerical order. First knock out the fastening pins -1- with a hammer and punch. Instead of a punch, you can use a nail.

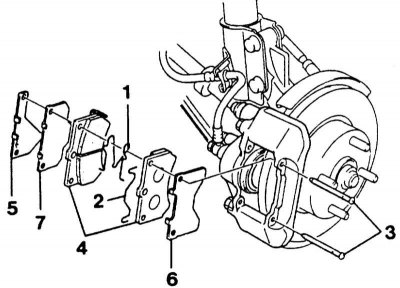

Vehicles since 10/89, except model "station wagon"

1. Remove individual elements in numerical order. First use a screwdriver to remove retaining springs -1- and -2-, paying attention to installation position. Then knock out the fastening pins -3- with a hammer and a drift or a nail.

Attention! Replace loose mounting pins.

2. Remove the brake pads and intermediate (anti-creaking) plate with pliers, a screwdriver or an impact puller. If the pads are rusted, a special puller is needed (e.g. HAZET).

Installation

Attention! When the brake pads are removed, do not press the brake pedal, otherwise the piston will be squeezed out of the housing.

1. Clean the guide surfaces and pad seatings in the housing shaft with a suitable soft metal brush or wipe with a rag and alcohol. Do not use solvents containing mineral oils or sharp-edged tools.

2. Before installing the pads, check the brake disc for grooves by feeling it with your fingers. Grooved brake discs must be replaced.

3. Measure the brake disc thickness.

4. Check the anther and protective cuffs in the caliper for cracks. A damaged cap must be replaced, as penetrating dirt will quickly lead to leaks in the caliper. To do this, the brake caliper must be removed and disassembled (performed in the workshop).

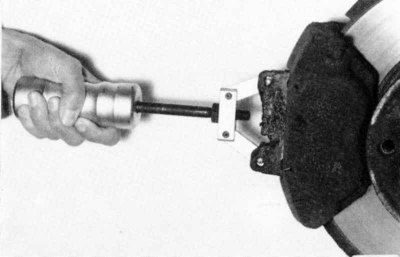

5. Press the brake piston with a special tool. This can also be done with a strong wooden rod (hammer handle), while making sure that it is not warped, and that the surfaces of the piston and boot are not damaged.

Attention! When the piston is pushed in, the brake fluid is forced out of the brake cylinder into the expansion tank. Observe the level of liquid in the tank, it is possible to pump out part of the liquid by suction. To pump out the brake fluid, use a suction pump or a plastic bottle that is intended only for brake fluid. Do not use drinking utensils.

Attention! Brake fluid is poisonous and must never be sucked out by mouth through a hose. After replacing the pads, the mark must not be exceeded "MAX" on the expansion tank, as the liquid expands when heated. The escaping fluid flows down onto the brake cylinder, destroys the paintwork and causes corrosion.

Attention! In case of severe wear of the brake pads, check the ease of movement of the piston.

6. To do this, insert a wooden rod into the caliper and ask an assistant to slowly depress the brake pedal. The brake piston should move in and out easily. To check the other caliper must be removed. Make sure the piston does not fully extend. If the piston stroke is heavy, repair the caliper (performed in the workshop). If the piston accidentally pops out, after installing the piston, the brake system must be bled, see Section Bleeding the brake system.

7. The following step is optional: To prevent disc brake squealing, coat the back and sides of the brake shoe base with anti-squeak paste (e.g. Plastilube, Tunap VC 582/S, Chevron SR/2, Liqui Moly LM-36 or LM-508-ASC). In this case, apply lubricant only on the reverse side.

Attention! The paste must never get on the brake lining or on the brake disc.

8. If necessary, immediately wipe off the paste and clean the place with alcohol.

9. Insert both brake pads with anti-squeal plates into the brake caliper.

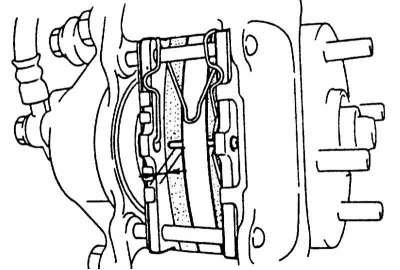

10. Check the springs and pins for fastening the pads, in case of severe corrosion and deformation, replace. Insert individual elements in reverse order, see illustration. Carefully hammer in the fastening pins with a hammer until they stop.

11. Caliper for models from 10/89 y. (except "station wagon"). Check the mounting position of the mounting springs. The outer spring is located in the mounting pin holes.

12. If screwed on, unscrew the wheel nuts. Screw the wheel, taking into account the mark on the hub. Lower the vehicle and tighten the wheel nuts crosswise with force 100 Nm.

Attention! Depress the brake pedal several times until a noticeable resistance is felt.

13. Check the brake fluid in the compensation tank, top up if necessary up to the Max.

14. Carefully run in new pads, to do this, reduce the vehicle speed several times from 80 to 40 km / h by slightly pressing the brake pedal. Take breaks in between to cool the brakes.

Attention! For the first 200 km, full braking should not be performed.